181~225 item / All 309 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile181~225 item / All 309 items

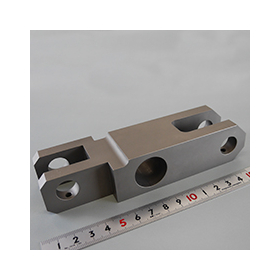

Introduction of processed parts achievements! 〇 Material: SUS304 〇 Processing method: Wire processing 〇 Surface treatment: Fluororesin (Teflon) coating These are wire-processed products made from SUS304. Wire processing allows for high-precision machining even for complex shapes. It enables the creation of products without knife R that cannot be processed with end mills, and by moving the upper and lower wires separately, taper shapes can also be machined. It is also possible to apply key grooves or finish with gear-cutting shapes. For surface treatment, a fluororesin (Teflon) coating is applied, which possesses properties such as non-stick, slip resistance, insulation, wear resistance, heat and cold resistance, etc. In this way, our company can provide one-stop solutions for processing, treatment, and inspection. We have production achievements in various industries, including industrial machinery, semiconductors, electronic devices, machine tools, printing machinery, construction machinery, etc. We specialize particularly in small quantities of various types, prototype parts, and development parts. We can handle everything from metals to plastics! Please leave the cutting processing of prototype and development parts to us. For company information and product details, please refer to the catalog available for download below, and feel free to contact us if you have any questions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◎Benefits of Using Our Services The procurement contact is exclusively with our company! Leave everything from processing to surface treatment to us! We also manage everything from process management to quality control in one go. Our strength lies in our "unique procurement system" that enables the efficiency and simplification of procurement operations. ◎Reasons With about 30 years of experience in procuring processed parts, we have built an extensive network in industrial machinery since our founding. We are now partnered with over 1,100 cooperating companies both domestically and internationally, capable of handling all types of processing needs. ◎Unique Strengths (Quality Assurance) We conduct inspections of all processed parts at our quality control center equipped with the latest digital measuring instruments such as 3D measuring machines and image dimension measuring devices. Issuance of inspection reports is also possible. ◎Features - Accepts small quantities of various types, starting from just one drawing and one part! - Contract processing technologies / MC cutting, lathe work, precision sheet metal, resin cutting, can manufacturing, wire, discharge machining, gears, etc. - Supported materials / Aluminum, iron, stainless steel, steel, steel plates, brass (copper alloy), plastic, etc. For processed parts achievements, refer to the catalog "100 Processed Parts." This is a "web-exclusive" catalog, featuring parts that are only listed here! We handle everything from metals to plastics! Trust us with the cutting and processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Material" Aluminum / A2017 (Duralumin) "Processing" NC milling processing This product is machined from aluminum material / A2017 (Duralumin). All processing is done by milling. The edges of the cut-out sections (tapered parts) are processed using the inclined part of the end mill. Since the plate thickness is about 3mm, care is taken during processing to avoid warping and distortion. For high-precision machining of aluminum plates and thin aluminum processing, please leave it to us. If you have any issues with precision aluminum parts, from milling and turning to sheet metal, please feel free to contact Agency Assist! We especially handle small quantities of various types, development parts, prototype parts, semiconductor manufacturing equipment-related parts, optical equipment parts, and industrial robot parts. We also accept surface treatments such as anodizing as a complete service. For our production achievements, please refer to the catalog available for download below. We can handle machining of prototype and development parts from metals to plastics!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Processing" Complex Lathe Processing "Material" Aluminum / A5052 (General-purpose Aluminum) This is complex lathe processing using A5052 (a5052). It fits perfectly with the same shape. We are particularly skilled at handling small items ranging from fingertip size to palm size. If you have any issues with precision parts made of [aluminum], please feel free to contact Agency Assist! We specialize in small quantities of various types, development parts, prototype parts, semiconductor manufacturing equipment-related parts, optical device parts, and industrial robot parts. For product details and company information, please refer to the catalog available for download below and feel free to contact us if you have any questions. Metal to resin is OK! Leave the cutting processing of prototype and development parts to us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

(1) Precision Aligned Palette (SUS430) Due to the specification of stainless steel, burrs were likely to occur, but we minimized them through processing methods and tool selection, finishing them to zero burrs as per the specifications. (2) Wafer Storage Case (Teflon / PTFE) There is no distortion or tolerance deviation, and the wafers are firmly aligned without any scratches, resulting in a perfect finish. (3) Vacuum Chuck Tip (A5052) We process with strict attention to avoid scratches and dents, ensuring that burrs do not affect product transport. Additionally, there are requirements for machining accuracy such as roundness and concentricity. (4) Probe Holder (PEEK / PK-450) This is precision machining of fine holes using PEEK material (PK-450), a super engineering plastic. Other achievements include numerous products! Pallets for product transport, specially shaped machined products, product transport plates, probe holders for substrate measurement devices, trays for work transport, cleaning mesh baskets, etc. For more achievements, please refer to the catalog "100 Processed Parts." Our official website contains more detailed information. We handle cutting processing for prototype and development parts, from metals to plastics!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

(1) Product Transport Plate (MC703HL) The MC703HL has a low friction coefficient, excellent sliding and gliding properties, allowing for the transport of products and use in slider applications without damaging the products and maintaining a sliding effect without lubrication. (2) Specially Shaped Processed Products (SKD11) We accept the production of processed products made from tool steel (SKD11). (3) Production Equipment Parts (A5052) Even with aluminum material (A5052), we have implemented machining to reduce weight by cutting out material in various places. The structure is lightweight, with no distortion or tolerance deviations after the material removal, resulting in a perfect finish. (4) Product Chucking Claws (Econol / Sumika Super S1000) The slit section is specified with a dimension tolerance of 0.7mm to the 1/100mm range, and the actual processing was done by a technician using a special metal saw with ingenuity. Additionally, we have numerous achievements! Vacuum chuck tips, wafer storage cases, precision alignment pallets, product transport pallets, probe holders for substrate measurement devices, work transport trays, cleaning mesh baskets, etc. The catalog contains more detailed information. From metals to plastics, we handle cutting processing for prototype and development parts with confidence!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

(1) Probe holder for base measurement device (Acrylic material) We processed fine holes for probe pins in acrylic material and completed the assembly by performing the actual press-fitting work for the probe pins. (2) Pallet for product transportation (A2017/Duralumin) Precision machining has been performed using a machining center. (3) Tray for work transportation (A5052S) We accepted the production of product positioning trays. We can arrange everything from anodizing to shot blasting. (4) Mesh basket for cleaning production equipment parts (SUS304) We finely welded a mesh made of stainless steel (SUS304) and assembled it with a reinforcing frame. Additionally, we have many achievements! Precision alignment pallets Probe holders Wafer storage cases Vacuum chuck tips Product transport plates Specially shaped processed products Production equipment parts Product chucking claws, etc. Our catalog contains more detailed information. From metals to plastics, we handle cutting processing for prototype and development parts with confidence!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Customer" Automotive Parts Manufacturer "Specifications" This is a device that checks for issues such as pinholes. It applies pressure with air to conduct leak tests on resin molding tanks. "Purpose of Introduction" The goal is to thoroughly manage the production of products and parts while also leading to labor savings through semi-automation of inspections. The washer tank pressure leak testing device (leak tester) can accurately detect minute leaks. This time, since there was a request for the inspection equipment to be arranged by the customer, we designed it based on that request and manufactured everything up to the connection parts, including assembly, adjustment, and wiring of sensors. Additionally, we can accommodate a wide variety of inspection items such as dimensional checks, identification of defective products by appearance, and foreign object detection. We provide devices that apply sensor and image processing technology for high-speed inspections. For more details about the devices and jigs, please refer to our company brochure. From metal to resin, we can handle cutting processing for prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Processing" Machining Center + Hard Anodizing "Material" A5052 (General-purpose Aluminum) Precision cutting processing using A5052 (a5052). We also handle various anodizing, plating, hardening, polishing, and other secondary processing in-house. If you have any concerns regarding [surface treatment], please feel free to contact Agency Assist! Especially for small quantities of various types, prototype parts, development parts, semiconductor manufacturing equipment-related parts, optical device parts, and industrial robot parts, please leave it to us. Additionally, our website features achievements in anodizing (black, white, color, hard), radiant, hardening, electroless nickel plating (Kanizen), gold and silver plating, etc. for precision parts. Please take a look. For company information and product details, please refer to the catalog available for download in the [PDF Download] section below, and feel free to contact us if you have any questions. From metals to plastics, we are ready to handle cutting processing for prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

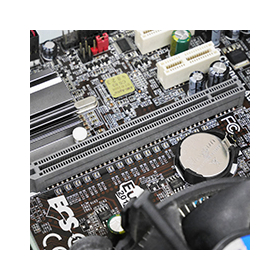

The Internet of Things (IoT) has advanced, and electronic components, including semiconductors, are now used in all kinds of products. There is a significant demand, and in some cases, supply cannot keep up, but there are things we can do. While our company cannot manufacture electronic components, we specialize in the design and manufacturing of equipment for automating, streamlining, and reducing labor in manufacturing lines, automatic assembly machines, parts feeders, inspection machines, and more, as well as parts procurement. For example, we can handle a wide range of needs from individual components related to printed circuit board manufacturing, plug components, winding machines, socket components, deposition equipment, and more, to complete sets of equipment. By becoming the sole procurement contact for our clients, we simplify procurement operations, improving efficiency and reducing labor. Additionally, we perform precise dimensional measurements in-house. We can deliver products even under strict precision requirements, such as components for semiconductor manufacturing equipment. To date, we have a track record of transactions with over 3,420 companies, including semiconductor, electrical, and electronic component manufacturers, as well as machinery manufacturers from various industries. We can handle machining of prototype and development parts made from materials ranging from metals to plastics. For more details, please refer to the catalog available for download below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the field of semiconductor packaging, there are various types of equipment such as wire bonding (bonder) machines, molding machines, forming machines and dedicated jigs, X-ray inspection equipment, and laser markers. Our company specializes in the procurement of processed parts for such precision machinery. ◎ Our Strengths - We handle a wide variety of small quantities, from a single drawing to one part, with processing capabilities including machining, turning, sheet metal, wire electrical discharge, and resin cutting. - We have numerous transactions with semiconductor manufacturers! With about 30 years of experience, achievements, and a network built around processed parts, we are well-established in the industry. - One-stop procurement from a single source for efficient purchasing operations. Dealing with multiple companies for different processing needs can be cumbersome. Our company can procure various processed parts in bulk based on a network of around 1,100 partner companies, simplifying the procurement process for our customers and enhancing production efficiency! We can handle everything from metals to resins! Leave the cutting and processing of prototype and development parts to us. For our production achievements, please refer to our catalog "100 Processed Parts."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the process of manufacturing electronic components such as resistors, filters, capacitors, power supplies, switches, and connectors, various devices and equipment are used to improve production speed and accuracy, as well as to streamline and enhance efficiency. As a fabless manufacturer specializing in precision machining parts, we have numerous transactions with electronic and electrical manufacturers. ◎ Production Achievements (Partial) *Due to confidentiality agreements, detailed descriptions will not be provided. For more information, please contact us. (1) Client: A certain major electronics manufacturer We accepted the production of maintenance parts for measurement devices. (2) Client: A certain semiconductor manufacturer This is a flange processed product made from aluminum A5052 (a5052). Details: It involves multi-process cutting using a composite lathe machining machine. (3) Client: Confidential This is a cutting process using Unichika's Unilate. It does not easily chip like paper bake, and is a very cost-effective material for semiconductor device parts and electronic devices. From metals to plastics, we can handle cutting processing for prototype and development parts. For details about our products and business, please refer to the [PDF Download] below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- Processed Parts Achievements 〈Material〉Steel / SS400 〈Size〉φ30mm 〈Processing〉Lathe Processing / Keyway Processing This product is a lathe-processed item made from SS400 (steel). It features keyway processing on the inside to prevent the shaft's rotational power from slipping. Additionally, we can accommodate spline processing with multiple keyways. We also support surface treatment and hardening polishing after processing. By requesting our services, you can eliminate the hassle of searching for specialized processing contractors! We provide comprehensive support from each stage of parts manufacturing to inspection, making it easy to procure parts. If you have any issues with keyway processing (slitting processing) or spline processing, please contact us! We have been providing processed parts to various industries for over 30 years. We offer quality assurance and have strong inspection technology. We are particularly well-equipped to handle small quantities of diverse types, development parts, prototype parts, semiconductor manufacturing equipment parts, industrial robot parts, and optical equipment parts. For more information on our processing achievements, please refer to the achievement catalog available for download below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Dear Customer" To the Comprehensive Machinery Parts Manufacturer "Purpose of Implementation" The goal is to automate the deburring process, which is currently done manually, through the use of robots. "Specifications" Burrs generated at the split of ring-shaped workpieces will be removed using a multi-axis robot. We received an inquiry about automating the deburring process, which is currently done manually and requires significant time and effort. We proceeded with the design of the robot. Taking into account the various sizes of the workpieces, we designed and manufactured everything from assembly to adjustment as a complete package. Our company offers a wide range of solutions, from original industrial robots to simple robots. For details about the deburring robot, equipment, and jigs, please refer to the "Company Information" section below. We handle cutting processing of prototype and development parts, from metal to resin! *Due to confidentiality agreements, we do not publish photos of the manufactured equipment. The images displayed are for illustration purposes only and do not represent the actual equipment.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have a wealth of experience in delivering prototype parts to industries such as industrial machinery, semiconductors, and electronics manufacturers. We specialize in small-batch, diverse projects for prototyping and research and development, and we can handle drawings with different processing technologies, accepting each part for "individual processing." We can accommodate all types of processing, including MC, lathe, sheet metal, resin cutting, wire, discharge, and gear processing, covering a wide range of projects! Additionally, - You can entrust us with all processing with materials provided. - We handle surface treatment comprehensively. - We perform precise dimensional measurements with our own inspection equipment, ensuring quality assurance. In other words, if you leave it to us, you can easily procure quality-assured "prototype parts" in single units, whether they are square or round, made from the appropriate materials. From metals to resins, we are your go-to for cutting and processing prototype and development parts. For our processing achievements in prototype parts, please refer to the "Achievement Catalog" below or visit our official website for detailed information. We invite you to take a look.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We often hear concerns about not having enough time for incoming inspections of machined products or pre-shipment inspections! As the required precision for quality increases, the burden of inspection tasks grows, leading to issues such as difficulty in measurement and insufficient man-hours. Our measurement services aim to clarify the problems related to "measurement and evaluation," thereby reducing the burden of inspection tasks. ┗ It is also possible to attach a "calibration certificate" for the equipment used in the inspection. ┗ We will provide the actual measured values of precise dimensional measurements and geometric tolerances in the "inspection report." Using the latest measuring equipment, such as CNC three-dimensional measuring machines, we inspect 60,000 parts monthly at our own inspection facilities. * For more information on our available equipment, please download the catalog for "Measurement Services (Precision Inspection)." We can accommodate various cases, including spot usage only when needed. We handle everything from metals to plastics! Leave the cutting and processing of prototype and development parts to us. For more details about our measurement services, please refer to our company brochure.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We can handle everything from quotes to processing, arrangements, and quality control as a one-stop service. 〔1〕Consultation Please let us know your requirements. Our dedicated technical sales team will assist you. 〔2〕Drawing Estimates We can accept drawings with different processing requirements, starting from just one part. We will provide a quick estimate response. 〔3〕Order We will fully comply with confidentiality agreements. 〔4〕Part Manufacturing and Arrangement We have various processing technologies such as MC, lathe, sheet metal, wire, and resin cutting. We can process a wide range of materials including aluminum, iron, stainless steel, resin, brass, and plastic. 〔5〕In-house Inspection 〔6〕Surface Treatment We accept surface treatments, hardening, plating, and various anodizing processes all in one go. 〔7〕Final Inspection Using CNC three-dimensional measuring machines and image dimension measuring devices, our inspection technicians conduct thorough inspections to ensure quality assurance. 〔8〕Delivery With an in-house logistics department, the process from inspection to delivery is smooth. For more details, please refer to the company information below. We handle everything from metal to resin! Trust us with your prototype and development part machining.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company utilizes the latest digital inspection equipment to conduct over 60,000 inspections monthly, and we would like to introduce the flow of our measurement services. 1. Consultation on inspection items 2. Meeting: We will understand the inspection issues you are facing and provide proposals for solutions. 3. Quotation 4. Order and receipt of inspection items → We will also fully comply with confidentiality agreements. 5. Inspection: Our inspection technicians will conduct inspections at one of the largest precision inspection rooms in Kyoto Prefecture. 6. Return of inspection report and inspection items → Upon request, we can also attach calibration certificates for the equipment used in the inspection. 7. Delivery Using image dimension measuring instruments and CNC three-dimensional measuring machines, we can perform high-precision dimensional measurements that cannot be measured with calipers, such as geometric tolerance measurements. For measuring curved surfaces and virtual lines, we use a non-contact 3D scanner-type three-dimensional measuring machine to scan the actual item and handle everything from drafting to production in one go. We also possess numerous evaluation equipment, including component analyzers, surface roughness measuring instruments, Rockwell hardness testers, and roundness and cylindrical shape measuring instruments. From metals to plastics, you can trust us with the machining of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Material" A5056 (Aluminum Round Bar) "Processing" Composite Lathe Processing We have received a project for pin manufacturing. Our company can handle precision machined parts from "1 piece to several items." For aluminum cutting processing, please leave it to us. We can accommodate round shapes, square shapes, and complex geometries. With diverse processing technologies including milling, lathe work, precision sheet metal, wire, electrical discharge machining, and anodizing, we can respond to all types of processing needs. If you have any issues with [aluminum], please feel free to contact Agency Assist! We especially welcome inquiries for small quantities of various types, development parts, prototype parts, semiconductor manufacturing equipment-related parts, optical device parts, and industrial robot parts. For product details and company information, please refer to the catalog available for download below under [PDF Download], and if you have any questions, do not hesitate to contact us. From metals to plastics, we are ready to handle cutting processing for prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company is a fabless manufacturer specializing in precision machining parts. We can handle all processing from milling, turning, sheet metal, wire, electrical discharge, resin cutting, hardening, polishing, to surface treatment, all with material supply! "Materials handled are listed in the catalog." We have a track record of responding to 487,983 drawings annually, from small to large items, and from square to round shapes. ◎Point - We have partnerships with over 1,110 cooperating companies nationwide! We can handle various projects with diverse processing technologies. - We have approximately 30 years of experience and a robust network. - Our unique procurement system allows for a one-stop purchasing process, consolidating procurement contacts into our company for efficiency. - We conduct precise dimensional measurements with our in-house inspection equipment! Our inspection technicians ensure quality assurance using the latest digital measuring instruments. We can handle everything from metals to resins! Leave the cutting and processing of prototype and development parts to us. *For more details, please download our [Comprehensive Catalog] company brochure! ★Our Three Business Areas★ 1. Processing Parts and Procurement Business (from single part processing of various small quantities) 2. Machinery Business (from design to installation of equipment and jigs) 3. Measurement Service Business (measurement and evaluation of processed parts and developed products)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Material" SKS3 (Alloy Tool Steel) It has minimal deformation after quenching, and compared to SK material (tool steel), it deforms less than half. "Processing" Vacuum quenching + Sub-zero treatment "Features" - Excellent brightness due to vacuum quenching. - HRC (Rockwell hardness) is over 60, making it an ultra-high hardness product. - Achieved high precision dimensional tolerances and surface roughness through cylindrical and flat grinding. - Improved dimensional stability and wear resistance mechanical properties through sub-zero treatment. We also accept orders for multi-process products such as processing, quenching, and grinding all at once. For company information, details on processing and materials, please refer to the catalog available for download below. Additionally, our official website contains more detailed information. From metals to resins, please leave the cutting processing of prototype and development parts to us. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Crysta-Apex S7106 is equipped with a standard temperature compensation system that ensures the accuracy of the measuring instrument within an environment of 16°C to 26°C. It monitors temperature using temperature sensors for the measured object and sensors mounted on each axis scale, making it unaffected by temperature conditions. It allows for accurate and rapid measurements while guaranteeing the inherent precision of the measuring instrument, accommodating various shapes of workpieces. In our measurement service business, we take custody of inspection items, and specialized inspection technicians conduct inspections using the latest inspection equipment in a precision inspection room, tailored to customer requests. Please leave the creation of inspection reports and the inspection of processed parts and development items to us. Additionally, we can handle everything from metal to resin! Please trust us with the cutting processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◎Number of Partner Companies: 3,420 As a leading company in the procurement of processed parts, we have a vast network in the industrial machinery industry accumulated since our founding. We are creating a system where customers who require processed parts and industrial machinery can mutually benefit. ◎Drawing Response Capability: 487,983 sheets/year We receive various requests from numerous customers nationwide. To meet our customers' expectations, we are actively developing new partner companies to handle as many drawings as possible and have responded to a wide range of requests, including bulk orders across different fields. ◎Inspection Defect Rate: "Aiming for 0%" To deliver all products with assured quality, we have established a quality assurance system and conduct inspections in our quality control department. Under the customer-first principle, we are expanding our inspection environment and facilities to provide quality support that allows customers to use our products with confidence. For product details and company information, please refer to the catalog available for download below. Additionally, our official website contains more detailed information. From metals to plastics, you can rely on us for cutting processing of prototype and development parts. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Dear Customer, Automotive Parts Assembly Machine Manufacturer "Purpose of Introduction" The goal is to design the system not only to accommodate the material and shape of the items to be cleaned but also to consider the degree of dirt and the type of cleaning solution, thereby achieving effective cleaning. "Specifications" We have manufactured a cleaning device for oil filter painting cups. It is a simple structure ultrasonic cleaning device that includes a pump station, tank (SUS), wiring rack, ultrasonic oscillator (amplifier) installation shelf. Designed to meet your requirements and desired cost, it demonstrates low cost and high performance. To ensure sufficient strength for the device itself, we particularly paid attention to the welding strength of the tank section. In addition, our company can provide solutions tailored to various applications, including solvent cleaning, pure water cleaning, and complex cleaning devices. We aim to automate the cleaning process and improve cleaning quality to enhance labor efficiency. For more details regarding the device and fixtures, please refer to the company brochure available for download below. From metals to plastics, we are your go-to for machining prototypes and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Processing" Composite Lathe Processing "Material" A5052 (Aluminum Material) This is composite lathe processing using A5052 (aluminum material). There are variations and different sizes, but all were processed by our company. Our company can handle requests for high-precision, diverse, and small-lot composite lathe processing, from single-item processing to bulk arrangements. If you are in need of precision parts made from aluminum, please feel free to contact Agency Assist! In particular, we specialize in prototype parts, development parts, diverse small lots, semiconductor manufacturing equipment parts, optical device parts, and industrial robot parts. For product details and company information, please refer to the catalog available for download below. Additionally, our official website contains even more detailed information. We handle cutting processing for prototype and development parts, from metals to plastics!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"In August 2018, we upgraded our image dimension measuring device to the latest version." ◎IM-7030 [Image Measurement] Field of View: Wide Field Measurement Mode: 300 x 200 mm (Corner R50) High Precision Measurement Mode: 225 x 125 mm Minimum Display Unit: 0.0001mm (0.1μm) XYZ Stage: 200 x 100 mm x 75 mm (Electric) Load Capacity: 7.5kg [Light Probe Measurement] Measurable Area (XY): 190 x 90 mm Maximum Measurement Depth: 30 mm *We also have another model of the image dimension measuring device, "IM-8000." "Features" Measures 100 workpieces at up to 99 locations in just a few seconds. Height and depth can be measured simultaneously. Automatically reproduces the lighting conditions set once, and automatically recognizes edge areas, eliminating human error. For details on our measurement service business and company information, please download the PDF from the link below. From metal to resin, we handle cutting processing for prototype and development parts with confidence.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will take custody of your products and our inspection technicians will perform precise dimensional measurements. This is a measurement service that we can offer because our company has pursued and achieved high-quality management through the procurement of processed parts. ◎ Features 1: Inspection of 60,000 processed parts per month We possess one of the largest "precision inspection rooms" in Kyoto Prefecture, along with numerous digital measuring instruments such as "image dimension measuring devices" and "CNC three-dimensional measuring machines," allowing us to conduct inspections of 60,000 items monthly. 2: Creation of inspection reports We will provide the actual measured values of precise dimensional measurements and geometric tolerances in an "inspection report." It is also possible to attach the "calibration certificate" of the equipment used for the inspection. 3: Abundant inspection equipment - Image dimension measuring device (Keyence) - CNC three-dimensional measuring machine (Mitutoyo) - Roundness and cylindrical shape measuring machine (Mitutoyo) - Eccentricity measuring gauge (Universal Punch Co.) - Rockwell hardness tester (Mitutoyo) - Surface roughness measuring instrument (Mitutoyo) - Digital height gauge 700 (TESA) and many others From metals to plastics, we are ready to handle the cutting and processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Material" S45C (Carbon Steel) "Processing" NC Milling + Wire Processing This is milling and wire processing using S45C (carbon steel for machine structures). The right angles of the square holes are well-defined. Our company can handle requests for high-precision, small-batch, and diverse NC milling + wire processing in a consolidated manner. If you are having trouble with precision parts made of [iron], please feel free to contact Agency Assist! We especially welcome inquiries for diverse small-batch production, prototype parts, development parts, semiconductor manufacturing equipment parts, optical device parts, and industrial robot parts. For product details and company information, please refer to the catalog available for download below. Additionally, our official website contains even more detailed information. From metals to plastics, you can rely on us for cutting processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our strengths lie in "procurement efficiency" and "information capability in the industrial machinery sector" for parts procurement. In the field of equipment manufacturing, we utilize our network to provide a one-stop service from design to production and installation. "Flow until delivery (example)" [1] Inquiry We will hold discussions based on the specifications. [2] Proposal (Concept review / Quotation preparation) Our technical sales team will provide proposals. [3] Order placement We will ensure comprehensive measures regarding confidentiality agreements. [4] Design (Mechanical & Electrical) [5] Design approval [6] Parts arrangement We manage procurement and quality comprehensively! / Purchased items & custom orders [7] Assembly & adjustment (Electrical assembly) Debugging / IO check [8] Supervision (Running test) [9] Delivery We will also handle installation. [10] Trial operation We will bring it to a state ready for immediate use. [11] After follow-up We will provide support even after delivery. For more details, please download the catalog! From metals to plastics, we handle cutting processing for prototype and development parts with confidence.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Material" Iron / S45C (Carbon Steel) "Processing" Machining Center This is machining using S45C (carbon steel for machine structures) on a machining center. We also accept processing of complex shapes like this. If you are having trouble with precision parts made of [iron], please feel free to contact Agency Assist! We especially welcome orders for small quantities of various types, prototype parts, development parts, semiconductor manufacturing equipment-related parts, optical equipment parts, and industrial robot parts. Additionally, our website provides detailed explanations about precision parts made from steel (S45C, SS400), aluminum (A5052, A2017), and stainless steel (SUS303, SUS304), so please take a look. For product details and company information, please refer to the catalog available for download below. Don't hesitate to contact us. Moreover, our official site contains even more detailed information. From metals to plastics, you can trust us with your machining needs for prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Features" Measurements can be taken even for objects with protrusions or where the circumference of the circle is not fully established. Not only roundness and circularity, but also flatness and other parameters can be measured with high precision. - Maximum measurement diameter: φ300mm - Maximum load capacity: 30kg - Equipped with automatic centering adjustment function In our measurement service business, we take custody of your inspection items and conduct a thorough inspection with the latest inspection equipment and a team of 10 inspection technicians in our precision inspection room. Do you have production equipment but cannot perform pre-shipment inspections? Are you facing issues with the time it takes for inspections? Our company has one of the largest inspection rooms in Kyoto Prefecture and numerous digital measuring instruments, allowing us to understand and solve the problems you face in measurement and evaluation. For more details about our measurement service business and company information, please refer to the catalog available for download at the bottom under "PDF Download." Additionally, our official website contains even more detailed information. From metals to plastics, you can trust us with the machining of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Material" A5052 (General-purpose aluminum) "Processing" Composite lathe processing + black anodizing After composite lathe processing of A5052 (aluminum material), black anodizing treatment is applied. Our company offers comprehensive services, including surface treatments such as anodizing, starting from single-item processing. Even for products involving multiple processes, our company manages everything in-house and takes responsibility for finishing them to completion. If you are facing issues with precision aluminum parts, please feel free to contact Agency Assist! We especially welcome inquiries for small quantities of various types, development parts, prototype parts, semiconductor manufacturing equipment-related parts, optical equipment parts, and industrial robot parts. For product details and company information, please refer to the catalog available for download at the bottom under [PDF Download]. Additionally, our official website contains even more detailed information. From metals to resins, you can trust us with the machining of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

As the demands for the precision of mechanical parts and surface treatment increase, surface roughness measurement is important for managing the finished state and mechanical properties. "Touch Probe Surface Roughness Measuring Instrument Features" - Capable of measuring long distances - Clear shape waveforms can be obtained "Measurement Range" - X-axis (horizontal direction) 100mm - Z1-axis (detection part) 8μm, 80μm We provide actual measurements of geometric tolerances in the inspection report. Additionally, we can attach calibration certificates for the equipment used in the inspection upon request. Our company actively introduces various digital measuring instruments, including the evaluation-type surface roughness measuring instrument (Mitutoyo) SV-3200S4. Please trust us with the inspection of development products and processed parts. For details on our measurement services and company information, please refer to the catalog available for download at the bottom under "PDF Download." Furthermore, our official website contains more detailed information. From metals to plastics, please leave the cutting processing of prototype and development parts to us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you struggling with the time and cost of sourcing parts from different suppliers? Our company can handle various processing and stages (metal cutting, precision sheet metal, grinding, etc.) all at once! By taking care of ordering, delivery, and quality control, we aim to simplify and streamline your procurement operations. Additionally, we support the procurement of small quantities of various parts for research and development and prototypes, starting from single-item processing! ◎ Features 1: We can handle single-item processing for a wide variety of small quantities of parts. We work with materials such as aluminum, stainless steel, iron, and resin, covering everything from small to large items, including heat treatment and surface treatment. 2: Single-source purchasing We can handle everything from milling, turning, sheet metal, laser cutting, welding, wire and discharge machining, can manufacturing, to resin and rubber, heat treatment, polishing, and surface treatment, consolidating your procurement sources into one. This achieves simplification and efficiency in your operations. 3: Quality assurance We have the latest inspection equipment, such as three-dimensional measuring machines and image dimension measuring devices, and we conduct inspections at all locations in our company. ◎ Partner Companies We have a network of over 110 companies that can handle various processing and surface treatment. ◎ Transaction Records We have dealings with 3,420 companies (industrial machinery manufacturers, semiconductor manufacturers, and various other manufacturers). From metals to resins, we are your go-to for cutting and processing of prototype and development parts!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There are size differences and variations, but all have been processed by our company. We can also handle requests for small quantities of various types and precision NC milling machine processing in a consolidated manner. If you are having trouble with precision parts made of aluminum, please feel free to contact Agency Assist! In particular, please leave it to us for small quantities of various types, development parts, optical device parts, prototype parts, industrial robot parts, and semiconductor manufacturing equipment-related parts. Additionally, our website provides detailed explanations about precision aluminum and stainless steel processed parts. (Link below) From metals to plastics, leave the cutting processing of prototype and development parts to us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company can handle orders for a variety of low-volume, high-precision MC machining products in a consolidated manner. If you are facing issues with precision parts made of stainless steel, please feel free to contact Agency Assist! In particular, we welcome inquiries for a variety of low-volume, development parts, prototype parts, optical device parts, industrial robot parts, and semiconductor manufacturing equipment-related parts. Additionally, we can handle machining for both metal and resin! Please leave the cutting of prototype and development parts to us. We also provide detailed explanations about aluminum precision machining parts and stainless steel precision parts on our website, so please take a look. (Link below)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In quality management engineering, hardness testing plays an important role. Rockwell hardness (HRC) - It is the most common evaluation method. - It is suitable for most metals. - It can measure samples with a maximum size of height 180mm and depth 165mm. - Due to the relatively high measurement pressure, it is not suitable for thin materials. - The evaluation is based on the depth of indentation after a single push, which reduces the effect of surface hardening. Are you struggling with inspection issues, such as being unable to issue inspection certificates? Our company actively expands inspection facilities and environments, including the Rockwell hardness testing machine (hardness tester) Mitutoyo HR-110MR and the latest digital measuring equipment, allowing us to understand and solve the problems you face in measurement and evaluation. For details on our company and measurement services, please refer to the catalog available for download at the bottom under "PDF Download." Additionally, our official website contains more detailed information. From metals to plastics, you can rely on us for cutting processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The area of response for procurement of processed parts covers all 47 prefectures in Japan! We provide precision processed parts with small lots, prototype development components, quality assurance included, and delivery management. By eliminating invisible costs, you can focus on improving your original productivity. We solve the complexities of purchasing and procurement, as well as the challenges related to manufacturing, to maintain quality and enhance productivity. "30 years of proven results! Over 1,110 partner companies!" Point 1: Supports single-item processing and small lots of various types. Point 2: Consolidates contact points with a dedicated technical sales guarantee system. Point 3: Inspections are conducted at our quality control center, specializing in quality assurance. Point 4: Drawings for estimates can be in either 3D or 2D. Point 5: We can handle drafting even without possible drawings. Point 6: We have a wide range of industry experience, including automotive, semiconductors, food, and medical sectors. Point 7: You can request parts made from various materials, including metals and plastics. "Commitment to Quality and the Environment" We have established an environmental management system compliant with ISO 14001 and promote environmental conservation activities. Aiming for "zero quality defects," we conduct final inspections in our quality control department. From metals to resins, leave the cutting and processing of prototype and development parts to us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer a wide range of design and manufacturing services for various specialized machines and jigs. Our "information power in the industrial machinery sector" enables us to provide "one-stop solutions" for parts procurement! In the field of equipment, we can handle the entire process from "meetings" → "design" → "parts procurement" → "assembly" → "quality control" → "delivery" all in-house. Former designers and experienced machinists serve as our main staff, solving all of our customers' requests and challenges. ◎ Features 1: One-stop solutions for the entire process from meetings to delivery. We handle the design and manufacturing of specialized machines and jigs all in-house. 2: We accommodate all cases, whether it’s "design and jigs only," "manufacturing with provided drawings," or "assembly." Our main staff consists of former designers and experienced machinists who solve all of our customers' requests and challenges. 3: Diverse lineup of design and manufacturing services "Jig design and manufacturing" / Mechanical design, electrical design, robot manufacturing, etc. "Machine design and manufacturing" / Automatic assembly machines, conveyors, mixers, semi-automatic devices, automatic supply devices, production equipment, etc. *For achievements, please refer to the basic information below. For more details, please download our company brochure. We can handle cutting processing for prototype and development parts, from metals to plastics!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company can also handle orders for various small quantities and high-precision NC composite lathe processed products in a consolidated manner. If you are having trouble with precision parts made of stainless steel, please feel free to contact Agency Assist! In particular, we specialize in various small quantities, optical equipment parts, prototype parts, development parts, industrial robot parts, and semiconductor manufacturing equipment-related parts. Additionally, we can work with materials ranging from metal to resin! Please leave the cutting processing of prototype and development parts to us. We also provide detailed explanations about aluminum precision processed parts and stainless steel precision parts on our website, so please take a look. (Link below)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We can process all variations in thickness and sizes of ultra-thin stainless steel materials at our company. We also accept orders for a variety of low-volume, high-precision laser-processed products in a consolidated manner. If you are having trouble with precision parts made of stainless steel, please feel free to contact Agency Assist! In particular, we specialize in prototype parts, low-volume diverse products, optical device parts, development parts, industrial robot parts, and semiconductor manufacturing equipment-related parts. Additionally, we can handle machining for both metals and plastics! Please leave your prototype and development parts machining to us. Our website also provides detailed explanations about precision aluminum and stainless steel parts, so please take a look. (Link below)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To differentiate our similar products, we individually engrave and finish each one. All processing has been done by our company. We can also handle orders for a variety of small quantities and high-precision NC milling products in a consolidated manner. If you are having trouble with precision parts made from S45C, please feel free to contact Agency Assist! In particular, we are well-equipped to handle a variety of small quantities, prototype parts, industrial robot parts, development parts, optical device parts, and semiconductor manufacturing equipment-related parts. Additionally, we can process materials ranging from metal to resin! Please leave the cutting of prototype and development parts to us. Our website also provides detailed explanations about aluminum precision processed parts and stainless steel precision parts, so please take a look. (Link below)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Features" This measuring instrument is designed and manufactured to sandwich the reference surface of the workpiece being measured with a three-point support roller, allowing for rapid and high-precision measurement of runout, concentricity, perpendicularity, cylindricity, etc. against the reference surface. The measurement accuracy is 2.5 to 4 microns. "Model Number": A-10/110-10FP Workpiece Diameter: 3.1 to 25mm, Workpiece Length: 76mm, Gauge Width: 114mm, Gauge Length: 216mm, Gauge Height: 73mm, Gauge Weight: 3.0kg "Model Number": B-40/140-40FP Workpiece Diameter: 20 to 102mm, Workpiece Length: 6.3 to 203mm, Gauge Width: 152mm, Gauge Length: 368mm, Gauge Height: 76mm, Gauge Weight: 7kg Our company possesses a wide range of measuring instruments. Additionally, we have a team of 10 inspection technicians dedicated to accommodating various measurements. For more information about our company and measurement services, please refer to the catalog available for download at the bottom under "PDF Download." Furthermore, our official website contains even more detailed information. From metals to plastics, you can rely on us for cutting processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is used as a tray for transporting workpieces in semiconductor manufacturing equipment. Our company can also handle requests for small precision machined parts with a variety of types and low quantities, along with shot blasting processing, all in one arrangement. If you are having trouble with precision parts for NC milling products, please feel free to contact Agency Assist! In particular, please leave the handling of various types and low quantities, prototype parts, industrial robot parts, development parts, optical device parts, and semiconductor manufacturing equipment-related parts to us. We can accept drawings in either 2D or 3D for quotations. Additionally, we can also create drawings for items without existing designs. Furthermore, we have catalogs available below that include examples and company profiles. We handle cutting processing for prototype and development parts, from metals to plastics!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company can handle high-precision NC lathe machining products and gear processing (hobbing) along with electroless nickel plating as a comprehensive service. These are used by our customers as gears for drive components. *Please feel free to contact us for more details. We accommodate everything from procurement of small quantities of various parts to surface treatment and inspection, including single-item processing. Our official website contains more detailed information. We can handle cutting processing for prototype and development parts, from metals to plastics!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration