271~309 item / All 309 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile271~309 item / All 309 items

We received a request from a semiconductor manufacturer. We accepted the production of a probe holder used for circuit board measurement. We processed fine holes in acrylic material for the probe pins and completed the assembly by actually performing the press-fitting of the probe pins. Our company can also handle requests for engineering plastic processing products related to insulation. Additionally, we can accommodate requests for rubber processing products (such as silicone rubber, urethane rubber, and NBR). *Please feel free to contact us for more details. Our official website contains more detailed information. From metals to plastics, you can trust us with the machining of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In our procurement model, we streamline all points of contact to eliminate the complicated tasks necessary for precision parts procurement! We accommodate a variety of processing needs from ultra-small lots starting from "1 piece" to mass production. "Features" - Easy ordering with a single point of contact - Supports small quantities of 1 to 2 pieces and single-item processing - Addresses various needs such as metal cutting, resin cutting, precision sheet metal processing, wire and discharge machining, gears, and more - Ensures quality assurance through double-checking at our three domestic quality control centers ◎ For VA/VE improvement materials and processing examples of machined parts, please download our free catalog from below. From metal to resin, trust us with your cutting processing for prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received a request from a semiconductor manufacturer to produce resin trays for wafer storage. This product is made using precision machining with polytetrafluoroethylene (PTFE). There is no distortion or tolerance deviation, and the wafers are aligned securely without any risk of scratching, resulting in a perfect finish. Our company can also arrange precision machining with trichloroethylene (PCTFE) and polytetrafluoroethylene (PTFE) in bulk, as well as accept single-item processing. *For more details, please feel free to contact us. Our official website contains even more detailed information. From metals to resins, you can trust us with the machining of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received a request from a semiconductor manufacturer. We have accepted the production of product transport plates made from MC703HL (material manufactured by Quadrant Polymers), a sliding grade MC nylon, for semiconductor manufacturing equipment. MC703HL has a low friction coefficient and excellent sliding properties, allowing for the transport of products and applications in slider systems without damaging the products and maintaining sliding effects without lubrication. Our company can also handle processing of such special resin materials, from single-item processing onwards. *For more details, please contact us. Our official website contains more detailed information. From metals to resins, you can trust us with the machining of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

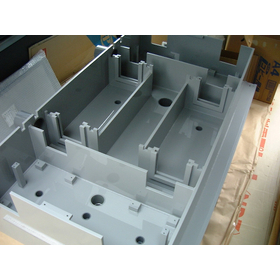

At the request of a major semiconductor manufacturer, we have undertaken the production of PVC tanks for use in lead-free plating lines. Since the tanks will be used for chemical flow, we used PVC that is resistant to alkalis and acids, and we performed welding (double) and adhesion, assembling them without any distortion. *For more details, please feel free to contact us. We handle everything from procurement of various small quantity parts to surface treatment and inspection, including single-item processing. Our official website contains even more detailed information. We can handle machining of prototype and development parts, from metals to resins!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the "Machinery Business" of Agency Assist, designers and experienced machinists are the main staff involved in the design and manufacturing of equipment. Leveraging the "efficiency of procurement" and "information power of industrial machinery" cultivated over 30 years of experience, we will also consider manufacturing together in the field of equipment. Aiming for a functional harmony of coexistence and mutual prosperity between machines and humans, we will shape our customers' ideas into reality. "Handling Achievements" ◎ Conveying Equipment ◎ Drying Equipment ◎ Packaging and Filling Machines ◎ Parts Supply Equipment ◎ Special Inspection Equipment, etc. From metal to resin, we are ready to handle cutting and processing of prototype and development parts. Our official website contains more detailed information. Please take a look. (Link below)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Products for semiconductor manufacturing equipment made from insulating super engineering plastics. We received a request from a certain semiconductor manufacturer to produce chucking claws. This involves ultra-precision cutting of resin using Sumika Super S1000 (formerly known as Econol). There was a specification for dimensional tolerances in the range of 1/100 mm, with a slit part measuring 0.7 mm. Therefore, our technicians used a special metal saw and devised a method for processing. Our company can also handle precision cutting of resin products made from such super engineering plastic materials, from single-item processing to larger orders. For other examples of resin processing and our achievements, please refer to the PDF download of the "Processed Parts Achievement Catalog" or visit our official website for detailed information. We can handle everything from metal to resin! Trust us with your prototype and development part cutting needs.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support resin machining and rubber machining for materials such as PEEK, MC nylon, Teflon, and POM. We accept parts processing for a wide range of industries, including semiconductor manufacturing equipment manufacturers, food, industrial, and medical sectors, as well as prototype and development projects. We offer extensive support for various resin materials, including resin machining, rubber machining, general-purpose plastics, rubber lining, engineering plastics, and thermosetting resins! "We can also accommodate the following requests!" - Manufacturing product chucking claws using insulating super engineering plastics (for semiconductor manufacturing equipment) - Precision resin machining using tetrafluoroethylene (PTFE) for producing resin trays for wafer storage - Processing probe holders using super engineering plastics (PEEK material: PK-450) - Manufacturing PVC tanks for resin plating lines using Unichika's Unilate - Resin machining using paper bakelite material We can accept drawings in either 2D or 3D formats for quotes. Additionally, we can create drawings for items without existing designs. Furthermore, we have catalogs available that include case studies and company profiles below. From metals to resins, you can trust us with your prototype and development part machining needs.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

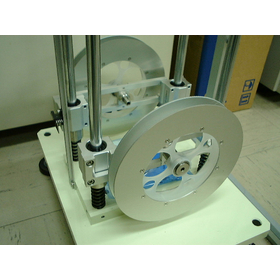

We received a request from a semiconductor manufacturing company to handle the procurement of parts, assembly, and adjustment of a taping winding device. We accommodate a wide variety of materials and types of parts, including aluminum, stainless steel, iron, resin, and plastic! We handle everything in-house, from single-item processing. *Please feel free to contact us for more details. Our official website contains even more detailed information. From metal to resin, you can rely on us for cutting processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We specialize in the fields of prototyping, research, and development, and can accommodate everything from a single part to small quantities of various types. - Metal processing of aluminum, stainless steel, and iron - Sheet metal processing using laser and press - Resin processing of industrial plastics - Alumina, ceramics, insulation materials, insulating materials, rubber, etc. From prototyping and single-item processing to multiple items, please leave the procurement of a wide variety of parts to us. Are you arranging NC milling, machining centers, lathes, wire cutting, electrical discharge machining, precision sheet metal, resin, rubber, hardening, and surface treatment with various specialized processing companies? By switching your order management, delivery management, price management, and quality management, along with material purchasing tasks, to our single-source management (consolidated arrangement), you can free yourself from unnecessary business management and improve operational efficiency with a one-stop service for arranging processed parts and material procurement. For more details, please refer to the catalog download "Company Profile" below. From metals to resins, leave the cutting processing of prototype and development parts to us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Flatness and parallelism 0.03. After flat grinding, EH-H treatment (Edison Hard) HRC 55~ Our company also offers various gas nitriding treatments, and this time we handled the Edison Hard treatment. This is not a surface hardening method that covers the surface, but a nitrogen-based diffusion-type surface hardening method that improves wear resistance and fatigue strength while maintaining dimensional stability, making it specialized for strict precision requirements! It is suitable for various mold components. For company information and details on materials and processing, please refer to the catalog available for download at the bottom under [PDF Download]. Additionally, our official website contains more detailed information. From metals to resins, you can rely on us for cutting processing of prototype and development parts. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Material" SKS3 (Cold Work Tool Steel) It is characterized by the ability to be hardened by air cooling with minimal dimensional changes. It has good machinability and is considered to be cost-effective. "Processing" Complex lathe machining Vacuum hardening Flat grinding Cylindrical grinding Sub-zero treatment It is finished to a hardness of HRC60 or higher through hardening. Sub-zero treatment is applied to prevent dimensional changes over time. Sub-zero treatment is performed for tool steels that require hardness and gauge steels that require dimensional stability. We can handle such multi-process products all at once. Communication is only with our company! Having a single point of contact saves time and effort. For other processing achievements, please refer to the [PDF Download] below. Detailed information is also available on our official website. From metals to resins, please leave the cutting and processing of prototype and development parts to us. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<Material> Stainless Steel / SUS303 <Processing> Fine Hole Electrical Discharge Machining <Size> φ5mm This product is a workpiece that has undergone fine hole electrical discharge machining on small-diameter stainless steel. A total of 8 holes with a diameter of 0.2mm and a depth of 5mm (blind holes) have been processed. Our company also accepts orders for precision micro-machining and fine hole electrical discharge machining like this. For other fine hole electrical discharge machining achievements, please refer to the "Processing Achievement Catalog" below. Additionally, detailed information is also available on our official website. From metals to resins, you can rely on us for cutting processing of prototype and development parts. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a shaft machined from S45C, with dimensions of L size 500mm and a diameter of Φ30mm. The shaft's axis has undergone high-frequency hardening (HRC 40-43). The fit tolerance for the shaft axis is indicated as g6, and it has been finished with cylindrical grinding. We can accommodate various grinding processes such as flat grinding, cylindrical grinding, and profiling grinding, as well as various heat treatments including high-frequency hardening, carburizing hardening, and vacuum hardening. Products with long processes can also be delivered as "finished products." For more details on our achievements, please refer to the achievement catalog available for download in PDF format below. You can view numerous examples of our hardening, grinding, and shaft machining accomplishments. Additionally, detailed information is also available on our official website. We can handle cutting processing for prototype and development parts, from metals to plastics! If you have any questions or concerns, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Strength 1" As a specialized trading company in manufacturing, we provide the necessary quantity at the necessary time and place, at a fair price. "Strength 2" Assistance with procurement of single processed parts We flexibly respond to the supply of small quantities of various parts for prototype development and research and development. "Strength 3" Easy ordering with a single point of contact By consolidating multiple suppliers into our company (single-source purchasing), we can significantly reduce the complicated tasks involved in parts procurement. "Strength 4" A team of procurement professionals on your side With our procurement staff specializing in secondary processing within our own system, we not only handle parts processing but also deliver complete products. "Strength 5" Reliable double-check system In addition to on-site inspections, our quality control department conducts thorough inspections of all items with its unique inspection system. Why not change the way you arrange parts a little to save on costs and time? Our company will support your parts procurement. Our official website contains more detailed information. From metals to plastics, leave the cutting and processing of prototype and development parts to us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

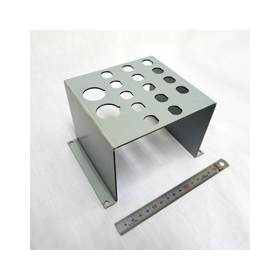

After laser processing, bending processing at 4 locations. Our company offers comprehensive sheet metal processing and laser processing for materials such as iron, stainless steel, and aluminum. For details on company information, processing, and material content, please refer to the catalog available for download in the section below. Additionally, our official website contains even more detailed information. We can handle cutting processing for prototype and development parts, from metals to resins! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a gear processing (spur gear) made of steel material. It is finished with high-frequency hardening to HRC 50-55. Our company can also handle multi-process complex lathe machining, slotting, and hob machining of such machine materials (SS400, S45C), aluminum materials (A2017, A5052), and stainless steel materials (SUS303, SUS304) as a single arrangement. For company information and details on materials and processing, please refer to the catalog available for download in the section below. Our official website contains even more detailed information. From metals to plastics, you can trust us with cutting processing for prototype and development parts. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a urethane rubber product with a hardness of 90°. Our company can also accept orders for rubber processed products such as urethane rubber, NBR, and silicone rubber. For company information and details on materials and processing, please refer to the catalog available for download in PDF format below. Additionally, our official website contains even more detailed information. We can handle cutting processing for prototype and development parts, from metals to resins! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce some examples of parts processing from Agency Assist as a reference in images. Various types of parts processing are possible as shown in the main image. We handle everything from procurement to processing, surface treatment (polishing), and inspection, including delivery management, starting from single-item processing. We process all kinds of materials such as aluminum, stainless steel, iron, resin, and plastic using methods like turning, milling, precision sheet metal, electrical discharge, and wire processing. Company information and helpful materials are provided below. From metals to resins, you can trust us with cutting processing for prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

After blackening the lathe-processed products, we braze a carbide ball with a diameter of φ3. Our company can also accept orders for such lathe-processed products along with blackening as a package. For company information and details on materials and processing, please refer to the catalog available for download at the bottom under [PDF Download]. Additionally, our official website contains even more detailed information. We can handle cutting processing for prototype and development parts, from metals to plastics! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a lathe-processed part made from SUS304 material that has undergone welding and machining. Two stainless steel (SUS304) lathe-processed parts are welded together, and a plug is also welded. Pickling is performed to remove any burnt residue. For company information and details on materials and processing, please refer to the catalog available for download below. Additionally, more detailed information is available on our official website. We handle cutting processing for prototype and development parts, from metals to resins!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using the F grade of Bess Thermo from Nikko Kasei. Finished with a tolerance of ±0.1 for φ71 through NC lathe processing. For company information and details on materials and processing, please refer to the catalog available for download below. Additionally, more detailed information is available on our official website. We handle cutting processing for prototype and development parts, from metals to resins! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

After welding the flat bar (FB) and square pipe, we perform surface finishing. There is a tolerance of ±0.03mm for parallelism on the top and bottom surfaces. Our company also accepts such fabrication and welding work. For company information and details on materials and processing, please refer to the catalog available for download at the bottom under [PDF Download]. Additionally, more detailed information is available on our official website. We handle machining of prototype and development parts, from metals to plastics! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To make more effective use of processing time at the manufacturing site, our company takes responsibility for the entire process from parts collection to delivery to the customer. This allows us to focus on parts production, enabling us to manufacture high-quality parts more quickly and at lower prices. Additionally, to further simplify and streamline the management tasks performed by our customers, we recommend total management services. For example, in a segmented process such as materials → raw materials → processing → heat treatment → painting, we encourage you to place orders for the entire product set. We have established a system where we procure materials and raw materials, transport them to the next process, and deliver the complete set to the customer on time. For more details about our company and business activities, please refer to the catalog available for download at the bottom of this page. Furthermore, our official website contains even more detailed information. Whether it's metal or resin, you can rely on us for cutting processing of prototype and development parts. If you have any questions or concerns, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a milled product made from fabric-reinforced Bakelite (phenolic resin). "Fabric-reinforced Bakelite material" is used for various applications such as insulation and heat resistance. It has higher strength than paper Bakelite and excellent mechanical properties. The surface retains a smooth finish while five sides have been machined. For company information and details on processing and materials, please refer to the catalog available for download at the bottom under [PDF Download]. Additionally, more detailed information is available on our official website. From metals to resins, you can trust us with the machining of prototype and development parts. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For stainless steel (SUS304), machining is performed, followed by wire electrical discharge machining due to the outer diameter being of irregular shape and thin-walled. Our company also accepts orders for wire electrical discharge machining, milling, turning, sheet metal work, etc., for stainless steel, iron, and aluminum. For company information and details on materials and processing, please refer to the catalog available for download in the section below. Additionally, our official website contains more detailed information. From metals to plastics, you can rely on us for cutting processing of prototype and development parts. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Frame / Welding of square pipe 75×75, t3.2. We have also accepted orders for surface grinding finish. Our company can also handle medium to large processing products like this. For company information and details on materials and processing, please refer to the catalog available for download at the bottom [PDF Download]. Additionally, more detailed information is available on our official website. We can handle cutting processing for prototype and development parts, from metal to resin! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a frame welding product (angle frame) made using steel SS400 / angle material (L3×40). The dimensions are approximately W: 800mm, H: 1,000mm, D: 700mm. This frame is for storage equipment that can manage a constant temperature and humidity, with the operation panel and control space on the left and the storage space on the right. We handled everything from material procurement to assembly welding and painting in-house. Please leave the frame, stand, and can manufacturing (bending, welding, assembly) to us. For other welded products, please refer to the processing parts achievement catalog available for download below. Detailed information is also available on our official website. We can handle cutting processing for prototype and development parts, from metal to resin! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

After canning processing, cutting processing was performed. There is a right angle on the top and side surfaces. Our company can also accept cutting processed products of medium size (around 500mm) to large size (around 1000mm). For company information and details on materials and processing, please refer to the catalog available for download in the [PDF Download] section below. Additionally, our official website contains even more detailed information. We can handle cutting processing for prototype and development parts, from metals to resins! If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

One drawing, one part, and we can accommodate various requests from single-item processing to multiple items! We will provide a quick estimate response. Please feel free to contact us. Vertical machining centers, five-axis controlled machining centers, horizontal machining centers, NC milling machines, general-purpose milling machines, and various types of machining and milling processes are available! "We can handle such processing too!" - Special shape processing - Processing of base plates for simple production equipment - Matte black anodizing and white anodizing finishes - Cutting processing for A5052 aluminum to reduce weight - We can also handle cutting processing for small to large items (around 2000mm) - Cutting processing of device parts such as brackets, bases, and manifolds - Processing of pallets for product transportation using A2017 material (Duralumin) You can view our processing achievements by downloading our catalog. From metals to plastics, we are your go-to for cutting processing of prototype and development parts. Simply attach your drawing and send us an email to request an estimate or processing order. We encourage you to give it a try!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Lathe machining is one of the most frequently requested processes, and we excel at it. We handle a wide variety of lathe machining, including general-purpose lathes, CNC lathes, multi-tasking lathes, screw machining, shafts, rolls, pins, flanges, and more! "We can also accommodate the following requests!" - Multi-process cutting of A2017 material (Duralumin) (multi-tasking lathe machining) - Precision lathe parts with h7 tolerance on the shaft and four key grooves (multi-tasking lathe machining) - Production of flange-type machined parts from A5056 material (CNC lathe machining) - C3604 (free-cutting brass) parts (various sizes) - End face grinding as a finishing process You can view our machining achievements by downloading our catalog. We can handle everything from metals to plastics! Leave your prototype and development part cutting to us. Simply attach your drawings and send us an email to request a quote or processing order. We invite you to give us a try!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We can handle everything from sheet metal processing (laser cutting, press bending) to surface treatment, buffing, and polishing. We specialize in prototype and small quantity sheet metal processing. We produce high-quality sheet metal products using laser cutting, turret punching, bending, and welding for aluminum, iron, and stainless steel. We offer a variety of products, from precision sheet metal processing of ultra-thin sheets to simple sheet metal products. We also accept surface treatments, including painting and silk printing. "We can also accommodate the following requests!" - Welding of angle materials - Bending after laser processing - Surface treatments with rust prevention effects such as painting finishes and trivalent & hexavalent chrome treatments - Punching metal t1 staggered pattern (laser → bending → spot welding → pickling → buffing) You can view our processing achievements in the catalog download. We can handle everything from metals to plastics! Leave your cutting processing for prototypes and development parts to us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We manufacture frames, platforms, ducts, and more through bending and welding. We handle everything from cutting and finishing after can processing to painting and plating, accommodating both single-item processing and bulk orders. "We can also accept requests like these!" - Surface finishing after welding - Baked-on painting You can view our processing achievements by downloading our catalog. We can handle everything from metal to resin! Trust us with the cutting of prototype and development parts. You can simply send an email with the drawings attached to request a quote or processing order, so please give it a try!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Wire electrical discharge machining that processes with complexity and precision using wire on narrow paths can handle electrical discharge machining capable of high precision even with hard metals. We can accommodate various machining needs, including shape-cutting electrical discharge machining and fine hole discharge machining. We can also handle the processing of complex-shaped products from single-item processing. We provide prompt quotation responses. "Processing Examples" - After machining, due to the outer diameter being irregular and thin-walled, we responded with wire electrical discharge machining. - Areas with significant material removal were processed using wire discharge, with a width tolerance of 0.05. Finished with Ni plating. - Machining of parallel teeth on the outer circumference; since the production quantity was one piece, it was manufactured using wire discharge, followed by tuft ride treatment. From metals to plastics, we are your go-to for cutting processing of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Manufacturing specialty trading company "Agency Assist." We provide quick estimate responses. Please feel free to contact us. "30 years of proven experience! Over 1,110 partner companies!" We can handle various large-scale machining products such as large gantry machining, frames, large diameter lathes, long lathes, horizontal boring processing, bases, transport shafts, long rolls, etc. "We can also accommodate requests like these!" - Welding square pipes to frames and finishing the top surface - Machining of large plates - Lathe processing of long items, etc. "Single item processing, quick estimate responses." ◎□ We handle everything from metals to plastics! Trust us with your prototype and development part machining. □◎ Our official website contains more detailed information. Please take a look. (Link below)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Manufacturing Specialty Trading Company 'Agency Assist'. We provide prompt quotation responses. Please feel free to contact us. 'Over 30 years of experience! More than 1,110 partner companies!' We handle various grinding processes such as flat parallel grinding, inner diameter grinding, cylindrical grinding, and profiling grinding, as well as quenching and long-process products delivered as finished goods! 'We can also accommodate requests like these!' - High-frequency quenching (HRC 55 and above) with cylindrical grinding finish at coaxiality ±0.01 - Flat grinding finish after high-frequency quenching - High-frequency quenching of shaft parts (HRC 40-43) etc. 'We provide same-day quotation responses!' ◎□ Please be sure to check our catalog download and feel free to contact us. □◎ Our official website contains even more detailed information. From metals to plastics, we are your go-to for machining of prototype and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Gears, gears, 3D printers, brazing, photopolymerization, laser welding, surface treatment, etc. 1. We are partnered with over 100 cooperating companies, allowing us to handle a wide range of processing. We also accept hardening and polishing, and by inspecting at our quality control center before delivery, we can reduce and improve productivity risks. If you are looking for a stable processing supplier, please feel free to contact us. You can rely on us for resin processing and metal processing. "A few examples of our work" - Brazing a φ3 carbide ball after blackening lathe-processed products - EH-H treatment (Edison Hard) Specific production achievements are listed in our production achievement catalog. From metals to resins, we are ready to handle cutting processing for prototypes and development parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"As part of our commitment to quality assurance" We have established the largest quality control department in Kyoto Prefecture and one of the largest in the Kinki region, staffed exclusively by certified inspection specialists. In conjunction with the adjacent logistics section, we efficiently manage the flow from "Receiving" → "Allocation" → "Manual Inspection" → "Precision Inspection" → "Packaging" → "Shipping." With an efficient layout and personnel allocation across each section, we conduct rapid and meticulous inspections of 60,000 products monthly. We have created a space where you can actually observe our consistent management system for product inspections. To ensure our customers' peace of mind, our company offers "Guided Tours" of the Quality Assurance Group. - Introduction to our quality management system - Overview of our business model - Examples of products we handle, and more From metals to plastics, we are your go-to for machining prototypes and development parts. More detailed information is available on our official website. Please take a look (link below).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are pleased to announce that we will be exhibiting at the "22nd Mechanical Components Technology Exhibition" from June 20 (Wednesday) to June 22 (Friday). On that day, we will showcase our company's single-source purchasing and one-stop service system, as well as our processing technologies. ◎ Exhibition Booth → 67-1, East Hall 5 "22nd Mechanical Components Technology Exhibition (M-tech)" ________________________ ◇ Organizer ◇ Lead Exhibition Japan, Inc. ◇ Venue ◇ Tokyo Big Sight Japan's largest specialized exhibition gathering mechanical components and processing technologies Co-located within Japan Manufacturing World 2018 are the following: - 3D & Virtual Reality Exhibition (IVR) - Design & Manufacturing Solutions Exhibition (DMS) - Healthcare & Medical Device Development Exhibition (MEDIX) ______________________________________________________ From metals to plastics, we are your go-to for cutting processing of prototype and development parts. We understand you may be busy, but we sincerely hope you will visit us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration