1~25 item / All 25 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~25 item / All 25 items

The "Tooling Production Case Studies and Problem-Solving Examples" is a collection of case studies featuring examples of tooling production and problem-solving by Fujimechanic Co., Ltd., including the "production case of quick-tightening nuts," which can be easily fixed without the need for specialized tools. For issues related to material selection and reducing processing time, we propose solutions that consider corrosion resistance, machinability, and processing time. 【Featured Cases】 ■ Production case of quick-tightening nuts ■ Clip-type detachable and easy to handle, ideal for process management ■ Wipers for wiping in clean rooms and laboratories ■ Usable work sizes ■ Material selection and reduction of processing time ■ Improved tearing due to insufficient strength. Soft taffeta towels ■ Review of cleaning processes and cleaning tools ■ Simple operation. Quick attachment and detachment of workpieces and tools ■ Cost reduction from tool selection ■ Eco-friendly lubricants for the environment and human health ■ Cleaning tools for small parts (glass, etc.) ■ Modification of in-house designed inspection tools ■ Reduction of working time. Transport racks ■ Processing methods that do not require deburring For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an example of a processing method that eliminates the need for deburring. **Issue** How to eliminate the deburring process after machining. **Solution** When using a right-hand twist end mill and machining from a consistent direction, burrs will form at the last edge, resulting in a deburring operation in the subsequent process. By using both right-hand and left-hand twist tools, it is possible to prevent the formation of burrs, leading to a reduction in machining time. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study on the production of a "transport rack" aimed at reducing work hours. 《Customer's Challenge》 We want to shorten the time taken to set up the equipment and reduce setup time. We also want to protect the fixtures from dirt and dust. 《Solution》 The fixtures are inserted and removed using a horizontal slide. A φ3 SUS rod at the back allows for adjustment of the extraction position. By attaching the handle slightly in front of the center, the rack is designed to lift at an angle, preventing the product from falling. 【Product Description】 ■ Custom-made racks tailored to your company's needs when off-the-shelf products are not suitable. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of a "Inspection Measurement Device Modification Jig." 《Customer's Challenge》 The inspection device was measuring surface accuracy from above, but we wanted to enable measurements from the side as well. 《Solution》 We designed the lens fixing part to be vertically adjustable, allowing it to be aligned parallel to the object at all times. 【Product Description】 ■ Material: Aluminum (lightweight) ■ Post-processing: Black anodizing ■ We also handle modification jigs for measuring devices used by the customer. ■ From in-house design to manufacturing. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is a case study of a "cleaning fixture for small parts (such as glass)." 《Customer's Challenge》 They want to clean small parts without scratching the products during the cleaning process. 《Solution》 The parts are surrounded by Teflon resin, making them less prone to scratches. The design ensures that the parts do not fall off during cleaning and that no liquid remains on the parts. 【Product Description】 ■ Ideal for cleaning parts with a diameter of 5mm or less or square parts of 5mm or less. ■ Custom fixture design is possible to match the product. * Coordination on specifications such as cleaning methods is necessary. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "chlorine-free water-soluble cutting and grinding oil S2015," which is friendly to the global environment and the human body. 《Customer's Challenge》 It can be applied to most work materials, but there are particular concerns about corrosion of aluminum. They want to continue using the liquid for 3 to 5 years and reduce waste liquid disposal costs. 《Solution》 There is no worry about discoloration or corrosion for non-ferrous metals such as copper and aluminum, and excellent results can be achieved with difficult-to-cut materials such as low carbon steel, stainless steel, titanium, and Inconel. Additionally, because it can be used for a long time, waste liquid disposal costs can be reduced. 【Product Description】 ■Packaging: 20-liter pail / 200-liter drum ■Samples available ■Ideal for companies certified with ISO 14001 For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"We select the appropriate cutting tools from various processed shapes to meet our customers' requests." Here is a case study. 《Customer's Challenge》 There was a relief groove at the bottom of the counterbore, making it impossible to process with commercially available end mills. Therefore, we collaborated with a tool manufacturer to create a custom tool. 《Solution》 The selection of cutting tools involves choosing the optimal tool shape, base material, and coating based on the workpiece, the machine tool used, the processing content, and the processing method. We also modify the processing content in-house to meet customer requests, which helps reduce tool costs. For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Easy operation! Quickly attach and detach workpieces and jigs. We would like to introduce a case of using spring roll pins. <Customer's Challenge> We want to reduce the assembly time of jigs. <Solution> Using a method that clamps the workpiece from both sides with plates and secures it with screws and nuts can be cumbersome during mass production when attaching and detaching. Therefore, we used spring roll pins to shorten the work time. <Product Description> ■ Customizable to your desired shape ■ Samples available For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Improving yield and workability through a review of the cleaning process and cleaning fixtures!" Here are some case studies. 《Customer Challenges》 We want to review the workability of the cleaning process and cleaning fixtures. We want to address contact scratches and stains on the workpieces. 《Solution》 Over 400 delivery achievements and a lineup of more than 1,000 types. We securely hold the workpieces and can accommodate all shapes. We also have a wealth of delivery experience in addressing contact scratches and stains. 【Product Description】 ■ High durability and corrosion resistance with stainless steel shafts, frames, and baskets. ■ Use of Teflon to reduce workpiece damage. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

If you are struggling with tears due to insufficient strength, we would like to introduce a case study of our "Soft Taffeta Towel Unbleached, which is resistant to tearing whether wet or dry." 《Customer's Challenge》 Paper wipers tear easily. We want to increase the strength a bit more. 《Solution》 For wiping and polishing tasks in a "wet state" with solvents, and for wiping off water and oil stains in a "dry state." We enhanced the strength both vertically and horizontally. 【Product Description】 ■ Sheet Size: 380×280mm ■ Individual Package Size: 50 sheets ■ Case Quantity: 24 packs ■ Material: 100% pulp ■ Form: Band-wrapped (Samples available / Purchase from case units) For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is a case study on "Material selection and reduction of processing time." 《Customer's Challenge》 The material needs to be corrosion-resistant, so stainless steel is preferred. The delivery time is urgent. 《Solution》 SUS304 is the most commonly used stainless steel, but we recommend SUS303. Compared to 304, it has better machinability, which can reduce processing time. 【Product Description】 ■ SUS303 contains sulfur (S) and phosphorus (P), which are elements that enhance machinability. ■ If welding is required, SUS304 will be used. ■ In addition to stainless steel, we can also process aluminum, brass, copper, iron, and plastics. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here are examples of "work sizes that can be accommodated." 《Customer's Challenge》 There are inquiries about processable sizes. The available machine tools vary depending on the processing method and content. 《Solution》 For large or thick workpieces, we propose a modular split design. For small or thin workpieces, we suggest reviewing the processing methods. 【Product Description】 By selecting equipment that matches the desired product size from a wide range of machine tools, you can reduce processing time and costs. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of creating "affordable-sized wipers with minimal lint and fiber shedding," which are ideal for wiping in clean rooms and laboratories. 《Customer's Challenge》 The standard size is too large for wiping optical components like lenses, resulting in poor work efficiency. 《Solution》 The standard size is 250×250mm, but due to its large size and poor work efficiency, we manufactured a custom size of 80×450mm. (Shipped in carton units) 【Product Description】 ■ Minimal lint and fiber shedding for wiping lenses and other optical components in clean rooms, and the affordable size improves work efficiency. ■ Custom sizes can be discussed based on usage. ■ Samples are available for shipment. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of "clip-type detachable and easy-to-handle laser-marked barcodes and QR codes," which is optimal for production management. 《Customer's Challenge》 They want to use barcodes and QR codes for production and inventory management. 《Solution》 We performed laser marking of barcodes and QR codes, making them resistant to fading even in strong alkaline cleaning lines and solvent lines, and reducing aging deterioration. We made them detachable with a clip design, facilitating their integration into existing processes. 【Product Description】 ■ Detachable clip shape made of stainless steel ■ High-precision engraving of barcodes and QR codes through laser marking For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce a case study of the "Quick Tightening Nut," which allows for easy and convenient fastening of screws, improving work efficiency. 《Customer's Challenge》 The customer requested a way to simplify the fastening process using screws and nuts. 《Solution》 Fastening with screws and nuts requires tools such as screwdrivers and wrenches, and can take more time than expected, especially for products that require frequent fastening. With the Quick Tightening Nut, fastening can be done in just a few seconds. 【Product Description】 ■ A nut that can be easily fastened without the need for special tools ■ Customizable to your desired shape ■ Fastens in approximately two and a half turns ■ Samples available for shipment For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Fujimechanic Co., Ltd. is the sales agent for cado air purifiers and humidifiers. Air Purifier [Features] Starting with the AP-C710S, which boasts the world's number one purification speed, cado's air purifiers are equipped with powerful fans. The filter captures particles as small as 0.09μm or less, effectively trapping PM2.5 as well. The filter is self-regenerating with photocatalysis. Humidifier [Features] With Zeoclear technology, it simultaneously suppresses bacteria in the water tank and in the air. Please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Metalworking Fluids ◆ Water-soluble type: Grinding fluids, Cutting fluids ◆ Oil-based type: Grinding fluids, Cutting fluids Maintenance Oils ◆ Lubricating oil ◆ Rust prevention oil ◆ Grease ◆ Vacuum pump oil Engine Oil (Verity brand) ◆ Automotive engine oil ◆ Motorcycle engine oil ◆ Racing engine oil ◆ Chemical products Factory Lubricating Oils (SAMIC brand) ◆ Processing oil ◆ Equipment lubricating oil ◆ Rust prevention/Removal agents ◆ Special lubricants

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

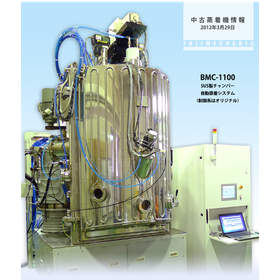

Vacuum deposition machines require maintenance once every 1 to 2 years under normal operating conditions. Our company has been involved in the maintenance, repair, relocation, and customization of various types of both old and new vacuum deposition machines and vacuum pumps. In particular, during maintenance work, we make it a point to disassemble the equipment down to its finer components and perform thorough cleaning.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The products handled by Fujimacanic Co., Ltd., "Elieair Pro Wipe," are made from paper and non-woven fabric and are used in clean areas, research and development facilities, and production factories. The clean area wipers are high-quality wipers suitable for wiping and maintenance, designed to minimize fluff and fiber shedding by being washed with high-pressure water flow and thermally bonding the fibers at high temperatures. You can choose from a rich lineup of paper wipers, paper cloths (brown/white), non-woven cloths, etc., according to the usage scene and application. [Features] ■ High quality ■ Selectable according to usage scene and application ■ Extensive lineup For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Case Studies of Tooling Production and Problem Solving" is a collection of examples featuring the production of "quick-tightening nuts," which can be easily fixed without the need for specialized tools, as well as examples of tooling production and problem-solving by Fujimechanic Co., Ltd. For issues related to material selection and reducing processing time, we propose solutions that consider corrosion resistance, machinability, and processing time. [Featured Examples] ■ Production case of quick-tightening nuts ■ Clip-type detachable design, easy to handle, optimal for process management ■ Wipers for wiping in clean rooms and laboratories ■ Available work sizes ■ Material selection and reduction of processing time ■ Improved tearing due to insufficient strength. Soft taffeta towels ■ Review of cleaning processes and cleaning tools ■ Simple operation. Quick attachment and detachment of workpieces and tools ■ Cost reduction from tool selection ■ Environmentally friendly lubricants for the earth and human body ■ Cleaning tools for small parts (glass, etc.) ■ Modification of in-house designed inspection tools ■ Reduction of work time. Transport racks ■ Processing methods that do not require deburring For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We manufacture various types and materials of polishing jigs, including coat jigs, cleaning jigs, lens wiping holders, core drilling holders, and rough grinding chucks. We also sell cleaning agents for optical lenses, glass substrates, and cleaning agents for precision cleaning. 【Other Jigs Available】 ○ Various types and materials ○ Proven track record in polishing jig manufacturing ○ Speedy processing ○ Production of new tools and jigs For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We can design and manufacture cleaning frames and cleaning rods suitable for each cleaning machine, taking into account the different sizes of cleaning tanks, water flow, and drainage depending on the manufacturer. The materials used for the cleaning rods mainly include PTFE (Teflon), POM (Delrin), and stainless steel. Upon request, we can adopt our unique special riveting method for the cleaning rods, which minimizes shrinkage of the blades due to temperature and special solvents. 【Features】 ○ Compatible with various manufacturers and sizes ○ Minimizes blade shrinkage through our unique riveting process ○ Shapes suitable for cleaning jigs For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company performs most of the processing processes such as material cutting, deep drawing, heat treatment, and hole processing for coating domes in-house, allowing for speedy designs tailored to customer requests. Additionally, we investigate and compare the residual stress distribution of coating domes before and after heat treatment, striving to minimize residual stress and produce coating domes with minimal deformation. 【Features】 ○ One-stop processing ○ Speedy design ○ High-precision hole processing ○ SUS material (stainless steel) For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company primarily engages in the design and manufacturing of corner jigs, round jigs, coat rings, triangular jigs, and more. We select blank shapes according to various lens types and design them under optimal conditions. Utilizing the know-how we have cultivated over many years regarding coating areas and usage conditions, we strive to design unique jigs and tools that satisfy our customers. In addition, during processing, we employ unique methods that minimize deformation, such as work clamping techniques and processing procedures. As a result, we can reduce dimensional errors associated with deformation. 【Features】 ○ Designed under optimal conditions ○ Simultaneous coating of multiple surfaces ○ Full surface coating ○ Reduced processing costs For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Fujimechanic has been continuously manufacturing tools related to the production of thin films and lens processing for various purposes such as the camera industry, semiconductors, and medical equipment since its establishment, and has grown into one of the leading manufacturers of optical tools in the industry. An important aspect of producing deposition tools is understanding the deposition process and considering the shape of the substrate and the deposition area. By using tools designed with the deposition process in mind, we can create products that fully satisfy the film characteristics and deposition area. Fujimechanic, as a specialized manufacturer of optical tools, is committed to consistent tool production from design to manufacturing, based on the know-how and achievements cultivated over many years, providing customers with peace of mind and satisfaction. To further enhance our services in the field of optical thin films, we will strive for improvement in technology and quality in collaboration with our group companies. 【Business Activities】 - Design, manufacturing, and sales of tools for polishing and coating optical device lenses - Machining of parts for optical devices - Optical glass polishing and cleaning systems - Sales of other consumables For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration