We also accept requests for pump maintenance modifications, relocations, and holiday support.

We provide vacuum deposition equipment and related maintenance services.

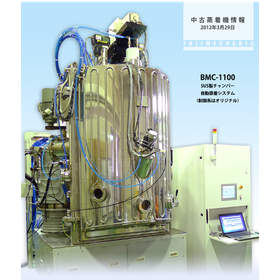

Vacuum deposition machines require maintenance once every 1 to 2 years under normal operating conditions. Our company has been involved in the maintenance, repair, relocation, and customization of various types of both old and new vacuum deposition machines and vacuum pumps. In particular, during maintenance work, we make it a point to disassemble the equipment down to its finer components and perform thorough cleaning.

Inquire About This Product

basic information

Please download the materials for information on handling and achievements.

Price range

Delivery Time

Applications/Examples of results

Vacuum deposition equipment, pump-related - Maintenance - Repair (including emergency parts lending) - Relocation (domestic and international) - Sale and brokerage of used equipment - Sale of parts and consumables (O-rings, gaskets, etc.) Manufacturers of equipment with maintenance records (deposition machines, MBP, RP): Synchron, Opttran, Showa Vacuum, ShinMaywa Industries, Vacuum Technology Institute, ULVAC, Maruyama Vacuum, Osaka Vacuum, Shibaura Eletech (Tokuda), Kashiyama Industries, Edwards, Alcatel, Leybold, Shinko Seiki, Shimadzu Corporation, etc.

catalog(1)

Download All CatalogsCompany information

At Fujimechanic, we uphold the principle of "sincerity" and strive to engage with our customers with a sincere attitude. We are constantly looking towards the new era, incorporating creativity and ingenuity to respond swiftly to our customers' needs, and we work diligently every day to improve. Since our founding, Fujimechanic has been involved in the manufacturing of thin films and the processing of lenses for various purposes, including the camera industry, semiconductors, and medical devices, and has grown to become one of the leading manufacturers of optical tooling in the industry. An important aspect of producing deposition tooling is understanding the deposition process and considering the shape of the substrate and the deposition area. By using fixtures designed with the deposition process in mind, we can create products that fully satisfy the film characteristics and deposition area. Fujimechanic, as a specialized manufacturer of optical tooling, is committed to consistent tooling production from design to manufacturing, based on the know-how and achievements cultivated over many years, providing our customers with peace of mind and satisfaction. To further enhance our services in the field of optical thin films, we will continue to strive for improvement in technology and quality, in collaboration with our group companies.