1~45 item / All 115 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~45 item / All 115 items

This case study collection summarizes the press processing of parts conducted by Hayano Research Institute. It features items such as the "Railway Rail Fastening Parts," which were produced using a dual-purpose mold specification in five processes, as well as "Cart Fixed Fittings for Factories" and "Construction Machinery BRKT." Additionally, we provide an overview of our main equipment, including the fiber laser processing system and 3D laser processing machine that we own. Please take a look. [Featured Cases] ■ Railway Rail Fastening Parts (Mass Production Press 1) ■ Railway Rail Fastening Parts (Mass Production Press 2) ■ Parts for Transformers (Mass Production Press 3) ■ Parts for Construction Machinery (Mass Production Press 4) ■ Cart Fixed Fittings for Factories (Mass Production Press 4) ■ Construction Machinery BRKT (Mass Production Press 5) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document provides an overview of electrical steel sheets, including the terminology and characteristics used by electrical steel sheet manufacturers, as well as examples of processing conducted by our company. It includes sections such as "Classification and Terminology of 'Electrical Steel Sheets'," "Processing Examples of Silicon Steel Sheets (Orient/Highlight)," and "List of Major Equipment." We encourage you to read it. [Contents (Excerpt)] ■ What is Electrical Steel Sheet? - "Electrical Steel Sheet" - Classification and Terminology - "Permeability" - Selection of "Electrical Steel Sheets" ■ Silicon Steel Sheets (Orient) - Directional Silicon Steel Sheets - Processing Examples (Mass Production) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing the main equipment of Hayano Kenko, which specializes in the production of automotive prototype sheet metal that achieves high precision, short delivery times, and a wide variety of products. The 'Keyence Hybrid Laser Marker' owned by Hayano Kenko solves the problems of those who have struggled with printing defects, providing higher quality workpieces. Equipped with an autofocus function, it accurately auto-detects the 【distance】 and 【position】 even for a wide variety of processed shapes, contributing to a reduction in printing errors and cost savings. This single machine resolves issues that arise during the printing process, such as slight tilts, misalignments during transport, and placement errors in manual operations. 【Other Main Equipment】 ■ Fiber Laser Processing System ■ Gantry Machining Center ■ 3D Laser Processing Machine *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco Co., Ltd., we have been handling various press and sheet metal products, primarily focusing on the prototype production of automotive press parts for 25 years. Leveraging our experience and knowledge, we have created the fire pit "Fire Base." This product, crafted by professionals in sheet metal processing, is designed to be "simple" and "easy to use," featuring [10-second assembly] and [compact storage]. It is a must-see fire pit for those who enjoy solo camping or want to experience convenient outdoor activities, which have become popular in recent years. We received the [Grand Prize] at the Tokyo International Gift Show 2021 contest! 【Product Specifications】 ■ Material: Black steel plate (SS400) ■ Size S: w220×d300×h190 (mm) M: w280×d450×h240 (mm) ■ Weight S: 2.5kg L: 4.9kg ■ Thickness: 2.3mm ■ Storage Size S: w300×d40 (including butterfly bolts)×h275 (mm) L: w450×d40 (including butterfly bolts)×h350 (mm) *For more details, please download the materials or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"petokku" is an interior brand for people and pets. With the keyword "living with pets," we create furniture and accessories that incorporate elements fostering the relationship between people and pets into everyday items used in daily life, proposing a rich lifestyle where people and pets can spend time together. We offer a shelf called "SHELF_S," which allows you to rearrange three sizes of shelves at your preferred positions, as well as "PET SPACE," "WALL RACK," and more. 【Lineup】 ■SHELF_S ■SHELF_M ■PET SPACE ■WALL RACK ■WALL HANGER ■DISH STAND *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenko Co., Ltd., we have been specializing in the prototype production of automotive press parts for 25 years, handling a variety of press and sheet metal products. This handbook has been created to leverage our experience and knowledge for the benefit of developers and designers. [Contents] ■ Basics of Prototype Sheet Metal Design ■ Cost Reduction (Process Change Edition) ■ Cost Reduction (Drawing Instruction Edition) ■ Quality Improvement ■ Company Introduction Our company proposes low-cost solutions for the shape processing and drawing of prototype parts by utilizing both sheet metal processing and press processing technologies and know-how. Additionally, we also perform sample processing of materials other than metal (such as titanium, rubber, brass, carbon, acrylic, etc.) using laser processing. Please feel free to consult with us! *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we offer laser processing services for 3D machining (solid work), 2D machining (composite processing), and special material composite processing (fiber). We have experience in prototype laser processing of various materials such as rubber, aluminum, brass, carbon, and acrylic, in addition to iron and stainless steel (SUS). We can accommodate mass production from a single piece using automated cell lines with 24-hour unmanned operation. ★ Please feel free to consult with us! 【We can assist with the following inquiries】 ■ I would like to cut a special material as a trial... ■ I want assistance in finding efficient cutting and processing methods... ■ I was turned down because the laser processing thickness is too thin... ■ I want to process products within my budget... and more. Our company offers cost reduction proposals from the manufacturing side. We will listen to the current issues from our customers and provide proposals that can solve those problems. *For more details, please contact us or download the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Do you have any of these concerns? "I requested machining, but the finished product was far from what I imagined..." "The finishing accuracy was poor..." "I want to try cutting processing with various materials and sizes..." Please consult with us! The textbook "Formulas Needed for Processing" clearly explains the characteristics of each drill and how to derive the appropriate formulas. [Contents] ■ Tools used 1-3 ■ Processing mechanism ■ Processing mechanism ■ Terminology explanation 1-3 ■ Importance of condition calculations ■ Formulas 1, 2 ■ Supplement on rotational speed calculations ■ Actual calculations ■ Flow of calculations ■ Points to note after calculations If you have any questions about materials or are struggling with parts processing, please consult with us. *For details, please view the PDF from the download or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"The Laser Processing Textbook" is a resource that includes essential foundational knowledge for component processing, such as the types of lasers and differences in processing machines that should be used according to various materials and plate thicknesses, as well as the principles of lasers. [Contents] ■ What is laser processing? ■ Characteristics of laser processing ■ What is gas cutting? ■ Principles of laser processing ■ Terminology explanation ■ Assist gas ■ Types of laser processing machines ■ Comparison of CO2 and fiber 《★ Consultations for sample processing of materials other than iron and stainless steel are welcome! Please feel free to contact us.》 *For details, please view the PDF available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"The Basics of Sheet Metal Knowledge - Weight and Pressure Edition" is a document that includes fundamental knowledge necessary for processing sheet metal components, such as calculations of pressure and weight applied to an area, and the tensile strength of materials. [Contents] ■ SI Units ■ About Pressure ■ Specific Gravity ■ Weight Calculation ■ Punching Force Calculation ■ Material Tensile Strength ■ Shearing Pressure Calculation ■ About Bending Pressure ■ Pressure Table *For details, please refer to the PDF available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Basic Knowledge of Sheet Metal - Materials & Surface Treatment Edition" is a document that provides essential knowledge necessary for the design of sheet metal parts, including the types of metals used in sheet metal processing and types of plating. [Contents] ■ Types of Materials ■ Types of Plating ■ Painting ■ Anodizing ■ Zinc Chromate Treatment ■ Cutting ■ Types of Screws ■ Tap Drill Sizes ■ Questions Arising from Drawings *For details, please refer to the PDF available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Prototype Sheet Metal Design VA/VE Technology Handbook】 This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at cost reduction and quality improvement. 【Manufacturing Case Studies / Handbook (Mold Finger)】 This handbook/case study is packed with tips for adopting molds, detailing the structure and manufacturing flow of the transfer mold peripheral device "Mold Finger," along with numerous manufacturing examples. *For more details, please refer to the handbook or case study available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A must-see for those involved with mold fingers! This handbook/case study is packed with tips for adopting molds, including the structure and production flow of transfer mold peripheral devices, "mold fingers," and many production examples. 【Contents】 ■ Basics of fingers (What is a transfer mold? What is a finger?) ■ Conceptual diagrams of fingers ■ Finger drawings ■ Parts production and assembly process from 3D data ■ Various finger case studies ■ Finger performance parts *For details, please refer to the PDF available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Ultra Thick Plate" is a cooking iron plate made by Hayano Kenko, a sheet metal company, known for its excellent heat retention and perfect for outdoor use. It is available in three sizes to suit different needs: - "Large size" for cooking for large groups, such as stews and hot pots - "Medium size" for grilling and enjoying various dishes - "Small size" for easy portability, ideal for solo camping As you use it more, it will develop a sense of wear, such as scorch marks and stains, making it a cherished item. ■ Features - Excellent heat retention - Develops a sense of use and attachment - Available in "Large, Medium, and Small" sizes to suit different purposes *For more details, please download the materials or check our website.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The grill artisan "Gryada" is a charcoal grill that allows you to easily enjoy authentic grilled dishes at small shops, office parties, and at home. It supports skewers, grill nets, and teppanyaki, and its compact size means you can easily cook anywhere without needing a specific space. The cooking results are juicy and tender thanks to the effects of far-infrared rays and steam, and cleanup is a breeze—just change the water in the tray! Please try this authentic grill set that only a metalworking shop can offer. ■ Features - Compact size that is easy to use in small shops and homes - Juicy and tender meat thanks to far-infrared rays and steam - Easy cleanup of ash and grease by simply changing the water in the tray - Low smoke for easier cooking *For more details, please download the materials or check our website.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing the main equipment of Hayano Kenko, which manufactures automotive prototype sheet metal with high precision, short delivery times, and a variety of products. Our company is equipped with both NC (numerical control) machines and a number of non-NC machines, allowing us to respond to prototype and one-off processing needs. From 3D laser processing to handcrafted items, we propose prototypes tailored to our customers' needs. 【Main Equipment】 ■ Fiber Laser Processing System ■ Gantry Machining Center ■ 3D Laser Processing Machine *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a wide variety of products. From 3D laser processing to handcrafted items, we propose prototypes tailored to our customers' needs. Focusing on prototype mold design and production, we realize cost reductions for our customers through VA/VE proposal techniques for existing parts. 【Proposal Example】 ■ Target: Designers/Product Developers ■ Work: Sheet metal products with formed shapes ■ Effect: Cost reduction through labor savings by consolidating press processing steps *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handcrafted items, we propose prototypes tailored to our customers' needs. We will introduce examples of our products, including prototype mold processed items "automotive prototype parts," sheet metal processed items "welded products (mass production)," and welded structural items "aluminum inspection jig bases." 【Main Products】 ■ Prototype mold processed items ■ Sheet metal processed items ■ Welded structural items *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenco specializes in the processing of prototypes using hydraulic presses and manual forging, and has expanded its business into the sheet metal processing industry. Currently, we utilize ZAS and steel simple molds to support everything from prototype processing to mass production, primarily in the automotive sector. We have also been involved in the prototype processing of press products for the automotive industry, starting from mold design and manufacturing. A thorough proposal of value analysis (VA) and value engineering (VE) is required, and through this process, we have accumulated technical skills and processing know-how. Focusing on three-dimensional shapes of sheet metal and press products, we also propose process consolidation using our unique molds. 【Key Technologies】 ■ Support from simple mold manufacturing to prototype processing ■ Process consolidation through the production of prototype simple molds *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

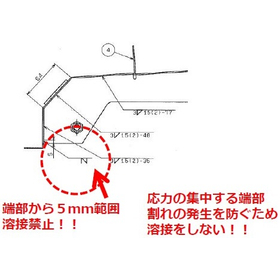

Welding should be performed up to the edge of the joint, and if bead buildup is done, it can lead to rapid progression of cracks in the cover. In cases such as covers for construction machinery and heavy equipment where significant vibrations occur, cracks often initiate from the welded bead at the stress concentration points and progress to the internal welds. To prevent the occurrence of cracks at the edges of covers where stress is concentrated, we intentionally avoid performing bead buildup. When significant vibrations occur, this approach helps prevent situations where the welded bead at the stress concentration points is directly affected, thereby enhancing the durability of the cover. *For more details, please refer to the PDF materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Since the joint section is processed with 'double pull', the weld buildup increases, leading to an increase in welding and finishing labor, which results in variations in the finish of the corners depending on the worker. If strength is not required at the welds, the joint sections can be processed with 'single pull', such as in box bending, to ensure that important dimensions are maintained. Alternatively, this can be noted in the drawing instructions and left to the manufacturer. By doing so, the corner welds can be made uniform and finished neatly. By considering the joint with single pull based on the necessary edges, variations in dimensions and corner finishes can be reduced, allowing for labor savings. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Sheet Metal and Welding Examples] Mass Production Press Forming Products SPHC 6mm Processing 120φ Rise 30mm At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to produce prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold manufacturing, and precision sheet metal. *For more information on Hayano Kenko's know-how, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Case】Welding Jig 1 A jig for clamping and welding two parts consisting of a pipe and six pressed components. Air-operated sliding structure. At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Sheet Metal and Welding Examples] Welding Jig (for Temporary Scaffolding Parts) Size: 1200 x 600 x 500 At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold fabrication, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Case】Prototype Sheet Metal Parts for Vending Machines SGCC 1.0–1.6 mm Parts 12 pieces Size: 900 x 800 x 200 At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal for research and development, automotive prototype sheet metal, mold production, precision sheet metal, and other applications. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Case】 Construction Machinery Duct Parts SPHC 1.6 to 2.3 mm Welding Structure (15 Parts) Robot Welding Size: 700 x 600 x 500 At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Examples】Prototype Parts for Commercial Air Conditioners (SPGZL 1.0mm) Size: 600x500x400 At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Sheet Metal and Welding Examples] Prototype Sheet Metal Parts for Commercial Air Conditioners (SPGZL 1.6mm) Size: 400x250x40 At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold manufacturing, precision sheet metal, and other products. *For more information on Hayano Kenko's know-how, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Examples】Laser Slit Sample 1 SUS304 2mm with 0.15mm Width Slit Processing At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to produce prototype sheet metal for research and development, automotive prototype sheet metal, mold manufacturing, and precision sheet metal. *For additional information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers on sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Examples】3D Laser Processing - Agricultural Machinery Parts Size: 1300 x 600 x 500 At Hayano Kenko, we utilize our expertise in welding technology and 3D laser processing to manufacture prototypes for sheet metal, research and development, automotive prototype sheet metal, mold production, precision sheet metal, and more. *For additional information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Case】3D Laser Trim (590kg High Tensile Material, 1.6mm) Size: 850x200x100 At Hayano Kenko, we utilize our expertise in welding technology and 3D laser processing technology to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for manufacturers regarding cost reduction and quality improvement in sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company handles parts from various industries, including automobiles and construction machinery. We can accommodate with our extensive range of shapes and molds, making mold-less processing possible. We propose the best manufacturing methods from the design stage. For customers who are considering prototype press sheet metal parts or want to reduce initial costs, we gently share our know-how for prototyping. We welcome consultations for prototypes from all types of businesses. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenko Co., Ltd., we offer 3D measurement services. With our measuring device "ATOS Core," we can digitize data from physical objects into 3D CAD, compare and verify physical objects against design data, and measure dimensions that cannot be measured with calipers. If you have any questions about 3D measurement, please feel free to consult with us. 【Service Details】 ■ Digitization of physical objects into 3D CAD ■ Comparison and verification of physical objects against design data ■ Measurement of dimensions that cannot be measured with calipers *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Metal Mahjong Tiles" are metal mahjong tiles that have been faithfully reproduced using precision machining equipment for commercial use, with a plated finish on the surface. They exude a sense of luxury from their delicate designs and substantial weight. They can be used as interior decor, auspicious items, or gifts. Each tile is made to order, allowing you to create the tiles you desire. We offer "Nickel Plating (Silver)" and "24K Gold Plating (Gold)" in our lineup. 【Features】 ■ Faithfully reproduced using precision machining equipment for commercial use ■ Plated finish on the surface ■ Delicate designs ■ Substantial weight and luxurious feel ■ Original product *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】 Agricultural Machinery Rotor Case At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to produce prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold manufacturing, precision sheet metal, and more. *For additional information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Prototype of Band Fittings At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal for research and development, automotive prototype sheet metal, mold production, precision sheet metal, and other applications. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Table Leg Fittings Chrome Plating At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for reducing costs and improving quality from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】SUS Eco Kura-kun At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Sheet Metal and Welding Examples] Vibration Device (Jig) At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Examples】Stair Fixture At Hayano Kenko, we utilize our expertise in welding technology and 3D laser processing technology to manufacture various products, including prototype sheet metal for research and development, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for reducing costs and improving quality from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Sheet Metal and Welding Examples] Other Fixture Manufacturing At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to produce prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold manufacturing, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for reducing costs and improving quality from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Examples】SPB Jig At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Welding Examples】SC Jigs At Hayano Engineering, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal for research and development, automotive prototype sheet metal, mold production, and precision sheet metal. *For additional information on Hayano Engineering's expertise, please refer to the handbook available for download. The handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenco offers prototypes tailored to customer needs, ranging from 3D laser processing to handmade products. "I want to request a prototype, but I don't know where to ask..." "I have a design, but I want to verify if it can be made." "I want to explore ways to reduce costs compared to now." "I'm struggling to keep up with production! I want to discuss mass production methods." "I want to reduce the number of parts and streamline assembly." In response to questions like "Can this product be made?", our company is here to help. Please feel free to consult us about small, one-off, or urgent products that may be difficult to request. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received a request from the customer regarding "drawing production." The content is, "We would like to produce the same specifications based on a product (actual item) obtained overseas." Our company will create product drawings or model data based on the actual item after discussing with the customer, and we will determine the necessary specifications with the customer's agreement. 【Proposal】 ■ Meeting with the customer ■ Creating product drawings or model data based on the actual item ■ Determining necessary specifications with the customer's agreement ■ Results - Understanding of product specifications, which can be used as a prototype - Providing feedback to the customer through production regarding any functional issues and the feasibility of commercialization *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration