1~45 item / All 61 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 61 items

Filter by category

In the lamination process of energy storage devices, positive and negative electrodes and separators are automatically stacked with high precision in any desired number of layers alternately. After lamination, the stacked body is fixed with tape and then aligned on a conveyor for operator retrieval. 【Features】 ■ Automatic tape application while fixed with a retrieval jig Since tape can be applied while the stacked body is securely fixed, it prevents misalignment and variation, ensuring consistently stable quality. ■ Automatically achieves high-quality finishes Regardless of skill level, anyone can achieve uniform and beautiful tape application. ■ Flexible setting of tape application position and quantity In addition to tape application at a total of four locations, two on each side, it can be flexibly set according to customer needs. This simultaneously improves the quality and efficiency of the lamination process, contributing to increased productivity for customers. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "TM-TE-21/46" is a device for necking cylindrical battery cases (such as 21700/4680 batteries). The touch panel allows for the setting and registration of various operation times. It can perform repeated necking operations based on pre-set parameters. Additionally, after necking, a lid can be set on the battery case, and it can be crimped using our crimping device. By changing the mold, necking of battery cans of different sizes can be performed. 【Specifications (partial)】 ■ Device mechanism: Table section (battery case set section)・Necking section (disk rotation section) ■ Safety device: Interlock on the device door, safety ensured by emergency stop button ■ Touch panel: Various operation time settings and registrations (3 types) ■ Device dimensions: w675×d250×h540mm (excluding the patrol light) ■ Device weight: 60Kg *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case regarding the development of a coater device that can use two heads. The request this time was for a roll coater that can use both a comma head and a die head. In the case we are presenting, we decided to forgo the "unit exchange type" because we wanted to minimize human operation during exchanges and reduce risks such as accidents. What the development team came up with was a method that encapsulates the unit, as shown in the image. Since it does not require optional parts and is quite reasonable in terms of cost, the customer was very pleased and decided to adopt it. 【Case Overview】 ■ Customer: Company ■ Application: Prototype of a battery ■ Request: A roll coater that can use both a comma head and a die head *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case where we added a drying oven to a roll coater as an after-installation at our company. In the initial design, the drying oven was configured with two units, but during use, we received a request to "add a drying oven." In response, we decided to add the drying oven after the completion of the equipment. The Sankmetal coater has a modular design for the drying oven section, allowing for the unit to be split and new units to be added even after the equipment is completed. The design allows for the addition of up to six drying ovens to a single coater, accommodating needs like the one mentioned. [Case Overview] ■ Customer: Company ■ Application: Battery prototype ■ Request: To add a drying oven to the existing roll coater *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

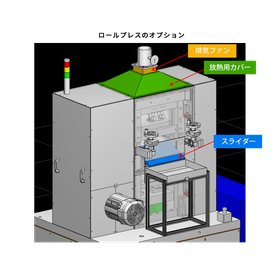

We would like to introduce a development case conducted by our company using the strip method. Unlike the winding method, the strip method requires manually pushing the material close to the roll. At this time, to prevent hands from getting caught in the roll, a safety cover is installed at the material's entry point. Normally, this specification meets safety measures, but the company we are introducing this time requested even higher safety standards. We considered whether it was possible to create a system that would eliminate the need to bring fingers close to the roll in the first place. This led to the creation of the roll press with a slider. [Case Overview] ■ Customer: Company ■ Application: Prototype of a battery ■ Request: To implement thorough safety measures to prevent hands from getting caught in the roll press *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce examples of options for improving work efficiency and heat dissipation measures that we have implemented. When processing materials with a strip-type roll press, collecting the finished materials one by one can be quite a labor-intensive task. To address this, we implemented a slider option. It may seem like a small change, but it has significantly improved work efficiency. [Case Overview] ■ Client: Company ■ Application: Battery prototype ■ Request: Measures for continuous use of the roll press *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CH-40100-3R" is a compact precision coater that uses an integrated unit of heat source and blower in a drying oven. It accurately coats low to medium viscosity materials on various metal foils and films, then dries the coated materials and laminates a film on top. 【Equipment Configuration】 ■ Unwinding Device: Tension control mechanism ■ Coating Head: Direct coat, transfer coat (intermittent, back coating possible) / Gravure coat (optional) ■ Drying Device: Integrated unit of heat source and blower in the drying oven Effective oven length: 1000mm × 3 ovens (optional) Drying capacity: 40℃ to 180℃ ■ Winding Device: Air chuck type, maximum load capacity 50kg ■ Laminating Mechanism: Film laminator *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This device is designed for the stacking process of lithium-ion secondary batteries, where the positive electrode, negative electrode, and separator are alternately stacked manually with precision. In the stacking process, the separator is supplied in a roll and is repeatedly folded in a zigzag manner, with the positive and negative electrodes being alternately supplied and stacked in the folds. 【Features】 - There is a receiving platform that alternately stacks the positive and negative electrodes between the folded separators, which moves up and down to maintain a constant height. - There are plates on both sides that constantly press down on the upper surface of the electrode plates during stacking, preventing misalignment of the stacked body and serving as a guide when folding the separator. - The work holding fixture has grooves for attaching tape, making it easy to apply tape. - It is compact (W900mm × D400mm × H600mm) and lightweight (70kg), allowing it to be installed in various locations. *For more details, please contact us or refer to the PDF download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company established the second and third factories within the premises of our first factory in Kato City, Hyogo Prefecture, in June 2023 to expand our manufacturing capacity for battery prototype equipment and the supply of expanded metal. With the increasing demand for battery prototype equipment against the backdrop of the proliferation of EV cars, inquiries from many companies and research facilities have been rising, as our coaters and press equipment can be utilized not only for battery component prototypes but also for other applications. In response to this, we are adding new machining centers to our existing factory and expanding the factory within the premises of our first factory to aim for an increase in equipment supply, enabling us to accommodate the manufacturing of large-scale equipment. Expanded metal is a mesh-like metal material originally developed by our company, and it is used in various applications beyond battery components, including sports goods, computers, and precision machinery parts. Previously, processing was done only at our Miki factory in Hyogo Prefecture, but recently there have been cases where it is also used in building materials, prompting the decision to expand the factory within the premises of our first factory. *For more details, please refer to the related links or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- This device is designed to accurately stack the positive electrode, negative electrode, and separator alternately during the lamination process of lithium-ion batteries. - The stacking process involves alternately supplying the positive and negative electrodes set in the stocker and the separator supplied by roll. - It is compact (W1200mm x D550mm x H650mm) and lightweight (approximately 80kg), making it suitable for various installation locations. - The stacking platform is equipped with a mechanism that constantly presses down on the top surface of the stacked body to prevent misalignment. - For the extraction of the stacked body, dedicated jigs are provided for different sizes. The dedicated jigs have space for immediately applying tape after extraction, making the taping process easy. - The dimensions of the electrode plates can accommodate sizes ranging from a minimum of 50mm x 50mm to a maximum of 150mm x 150mm. - The separator extraction is automated, extending to the set length and waiting.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing the groove cutting device 'TM-NE-2170' handled by Sunk Metal, which is rich in achievements, experience, and ideas. The cell sizes are 18650/21700, and it supports two sizes with jig replacement. Please feel free to contact us when you need assistance. 【Specifications】 ■ Supports two sizes with jig replacement ■ Cell sizes ・18650 ・21700 *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Vacuum Liquid Injection Device" is a device that injects a specified amount of electrolyte solution into cylindrical, rectangular, and laminated batteries under vacuum conditions. This product is a 'Cylindrical/Laminated Cell Compatible Type.' The cell sizes are □150X□150mm for laminated cells and 18650/21700 for cylindrical types. Please feel free to contact us when you need assistance. 【Specifications】 ■ Cell Size - □150X□150mm (Laminated Cell) - 18650/21700 (Cylindrical Type) ■ Injection Volume: Set according to battery size ■ Includes Measuring Pump / Vacuum Pump *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Vacuum Liquid Injection Device" is a device that injects a specified amount of electrolyte solution into cylindrical, rectangular, and laminated batteries under vacuum conditions. The "LamiCell Type" allows for the selection of suitable devices according to cell size from a wide variety of types. Cell sizes range from □150X□150mm to a maximum of □400X□400mm, and it comes with a metering pump and a vacuum pump. 【Specifications】 ■ Cell Size: □150X□150mm to a maximum of □400X□400mm ■ Injection Amount: Set according to battery size ■ Includes metering pump and vacuum pump *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Vacuum Liquid Injection Device" is a device for injecting a specified amount of electrolyte into cylindrical, rectangular, and laminated batteries under vacuum conditions. The "Cylindrical Type (also compatible with rectangular)" allows for various changes to the injection conditions. By exchanging fixtures, rectangular batteries can be used. The cell sizes are 18650/21700/Φ160, and both cylindrical and rectangular types feature a small vacuum chamber that allows for slight pressurization. 【Specifications】 ■ Cell Size: 18650/21700/Φ160 ■ Injection Volume: Set according to battery size ■ Includes metering pump/vacuum pump *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a compact type of "ultrasonic welding machine" handled by Sunk Metal, which has abundant achievements, experience, and ideas. It is designed for tab welding, and the pressing method uses an air cylinder. The maximum press stroke is 50mm, and the maximum pressing force is 500N, allowing for pressure settings between 0.2MPa and 0.7MPa. 【Specifications】 ■ Pressing method: Air cylinder ■ Press stroke: Maximum 50mm ■ Pressing force: Maximum 500N ■ Pressure setting: Setting range 0.2MPa to 0.7MPa or below *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Spot Welder," an assembly device handled by Sunk Metal, which has abundant achievements, experience, and ideas. It is used for welding the bottom of cylindrical battery cans, as well as for welding the top cap and tab. The control method is PWM control, with a welding current rating of 2kA and a power supply of 200V single-phase. Please feel free to contact us if you have any inquiries. 【Specifications】 ■ Power Supply: 200V single-phase ■ Control Method: PWM control ■ Welding Current Rating: 2kA ■ Output Frequency: 2kHz *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Air-operated Press Device" handled by Sank Metal, which is rich in achievements, experience, and ideas. With an air cylinder, it can crimp cylindrical and coin-type cells. Molds are available for cylindrical (18650/21700) and coin-type (2012). 【Specifications】 ■ Pressing method: Air cylinder (Air source: 0.5MPa, 50L/min) ■ Molds - Cylindrical - Crimping of coin-type cells/punching of electrode plates (Φ15/Φ16) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The device is a motor-driven single-sheet pouch forming machine. It uses a pouch shaping mold and can be easily operated with just a 100V power supply. Please feel free to contact us when you need assistance. 【Specifications】 ■ Press: Motor-driven ■ Mold: Pouch shaping mold *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The device is an air-driven automatic pouch forming machine. It consists of a unwinding device, pressing section, mold, and feeding device, with a stroke of 20mm. It continuously processes the forming of pouches in a roll-to-roll manner. Please feel free to contact us when you need assistance. 【Specifications】 ■Device configuration: Unwinding device / Pressing section / Mold / Feeding device ■Press: Air-operated ■Stroke: 20mm ■Mold: Die set mold / Punching mold / Pouch shaping mold *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "automatic stacking device" is a machine that cuts the positive and negative electrodes set in the stocker and the separator supplied in rolls to any desired length, and automatically stacks them alternately with high precision for any number of layers. The "4-head type" method first sandwiches the positive electrode with the separator from above and below, heat seals the separator into a bag shape, and then stacks the negative electrode on top. Manual or automatic operation can be selected via a touch panel, and the air pressure is above 0.4 MPa. 【Specifications (partial)】 ■ Electrode stock amount: thickness of 30mm or less ■ Electrode size: minimum 40mm x 50mm, maximum 100mm x 100mm ■ Separator width: maximum 100mm ■ Maximum roll diameter: 200mm ■ Inner diameter: 3 inches *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "automatic stacking device" is a machine that cuts the positive and negative electrodes set in the stocker and the separator supplied in rolls to any desired length, and automatically stacks them alternately with high precision for any number of layers. The "3-head type" alternately stacks the separator + negative electrode + separator + positive electrode + separator, and finally spot-welds the ends of the separator. The maximum width of the separator is 100mm, and manual or automatic operation can be selected via a touch panel. 【Specifications (partial)】 ■ Electrode stock amount: thickness of 30mm or less ■ Electrode size: minimum 40mm x 50mm, maximum 100mm x 100mm ■ Separator width: maximum 100mm ■ Maximum roll diameter: 200mm ■ Inner diameter: 3 inches *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "BHW-SII/SIII/SIV" is a compact and simple winding device. You can choose from three models based on the electrode size. The drive method is controlled by a stepping motor, and the winding core structure is round with a diameter of 4mm. Please feel free to contact us when you need assistance. 【Specifications (partial)】 ■Separator size: Width 40-70mm, Maximum winding diameter: Φ200 ■Winding dimensions: Φ8-25mm ■Drive method: Stepping motor control ■Winding core structure: Round Φ4 ■Weight: Approximately 500kg *For more details, please refer to the PDF document or feel free to contact us. *We have a demo unit available for the "BHW-SII" model.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "BHW-S1" is a compact and simple winding device. It is exclusively designed for strip-type electrodes and separators, with a winding core structure of round type Φ4. The drive method is controlled by a stepping motor, and the external dimensions are W1200 x D600 x H1400, with a weight of approximately 200 kg. 【Specifications (partial)】 ■ Electrode plate size: Width 40–70 mm, maximum length 800 mm ■ Separator size: Width 40–70 mm, maximum winding diameter Φ200 ■ Maximum winding diameter: Φ20 mm ■ Drive method: Stepping motor control ■ Winding core structure: Round type Φ4 *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The device is a low-cost, compact winding device. The electrode plate size is 25 to 50 mm in width and 150 to 300 mm in length, with a maximum winding diameter of Φ40 mm. The drive method is manual handle operation, and reverse rotation is also possible. Please feel free to contact us when you need assistance. 【Specifications (partial)】 ■ Electrode plate size: 25 to 50 mm in width, 150 to 300 mm in length ■ Separator size: 25 to 55 mm in width, 370 to 680 mm in length ■ Maximum winding diameter: Φ40 mm ■ Drive method: Manual handle operation (reverse rotation possible) ■ Winding core structure: Slotted winding core *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Slitter & Cutter." This machine can perform both slitting and cutting, with the slitting blade being a shear blade and the cutting blade a guillotine blade. It is driven by a variable-speed motor, and the material width ranges from 350 to 600mm. 【Specifications (partial)】 ■ Material width: 350–600mm ■ Slitting blade: Shear blade ■ Cutting blade: Guillotine blade ■ Slitting width: From 20mm ■ Drive: Motor-driven (variable speed) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Roll Press" is used by the coater to compress the applied composite material on the substrate to increase its density. The "Hydraulic 50t Roll Press" can handle up to 50 tons and a maximum roll width of 600mm. It comes with a digital clearance display device and a roll load indicator, with dimensions of W1800 x D2490 x H1920mm and a weight of approximately 6000kg. 【Specifications (partial)】 ■ Pressing capacity: 10 to 50 tons ■ Roll diameter: Φ360 ■ Roll width: 350mm (MAX 600mm) ■ Heating capacity: MAX 180℃ (optional) ■ Power supply voltage: AC200V/125A *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Roll Press" is used by the coater to compress the applied composite material on the substrate to increase its density. The "Hydraulic 30t Roll Press" can handle up to 30 tons and a maximum roll width of 600mm. The roll diameter is Φ400, and the heating capacity is up to 180℃ (optional). We offer a variety of options, including the "Roll Heating System," "Roll Widening (in 50mm increments)," "Area Sensor (Entrance)," and "Load Distribution Plate," so please choose according to your application. 【Specifications (partial)】 ■ Pressing capacity: 6–30 tons ■ Roll diameter: Φ400 ■ Roll width: 350mm (MAX 600mm) ■ Heating capacity: MAX 180℃ (optional) ■ Power supply voltage: AC200V/50A *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Roll Press" is used by the coater to compress the applied composite material on the substrate to increase its density. The "Air-Hydraulic 20t Roll Press" has a pressing capacity of 5 to 20 tons, with a roll diameter of Φ350 and a roll width of 350mm (MAX 500mm). We offer a variety of options, including the "Roll Heating System," "Roll Widening (in 50mm increments)," "Area Sensor (Entrance)," and "Load Distribution Plate," so please choose according to your application. 【Specifications (partial)】 ■ Pressing capacity: 5 to 20 tons ■ Roll diameter: Φ350 ■ Roll width: 350mm (MAX 500mm) ■ Heating capacity: MAX 180℃ (optional) ■ Power supply voltage: AC200V/50A *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Roll Press" is used by the coater to compress the applied composite material on the substrate to increase its density. The "Air-Hydro Type 10t Roll Press" is compact and high-pressure due to its air-hydro design. Its dimensions are W950 x D1250 x H1840 mm, and it weighs approximately 2000 kg. It has a pressing capacity of 2 to 10 tons, and the heating capability is up to 180°C (optional). 【Specifications (partial)】 ■ Pressing capacity: 2 to 10 tons ■ Roll diameter: Φ250 ■ Roll width: 250 mm (MAX 350 mm) ■ Heating capability: MAX 180°C (optional) ■ Power supply voltage: AC200V/40A * For more details, please refer to the PDF document or feel free to contact us. * A demo unit is available.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Roll Press" is used by the coater to compress the applied composite material on the substrate to increase its density. The "Mechanical 1-Ton Roll Press" is cost-effective and operates mechanically, equipped with a digital clearance display device. With a roll diameter of Φ160 and a roll width of 150mm, it has a maximum heating capability of 150°C (optional). 【Specifications (partial)】 ■ Pressing capacity: 1 ton ■ Roll diameter: Φ160 ■ Roll width: 250mm ■ Power supply voltage: AC200V three-phase/10A *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Coter" is a device that accurately applies a coating of a certain thickness to copper foil, aluminum foil, and films. The 'TH-C type Coter' is a precision type three-roll coater, with coating methods including direct coat and transfer coat (intermittent application). There are plenty of options available, and depending on your requirements, you can select the necessary options to provide the suitable coating device. 【Specifications (partial)】 ■ Coating method: Direct coat, transfer coat (intermittent application) ■ Coating head: Replaceable structure ■ Roll width: 350mm to 600mm (in 50mm increments) ■ Drying oven: 1000mm X 1 to 4 ovens (hot air method) ■ Power supply voltage: AC200V/100A *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Coter" is a device that accurately applies a coating of a certain thickness to copper foil, aluminum foil, and films. The "Small Precision Coating Machine 3-Roll Coter" allows you to choose between direct coating and transfer coating (intermittent application) methods. The coating head has an exchangeable structure, and the drying oven is 1000mm x 2 ovens (hot air method). There are plenty of options available, and depending on your requirements, you can select the necessary options to provide a suitable coating device. 【Specifications (partial)】 ■ Coating method: Direct coat / Transfer coat (intermittent application) ■ Coating head: Exchangeable structure ■ Roll width: 250mm to 500mm (in 50mm increments) ■ Drying oven: 1000mm x 2 ovens (hot air method) ■ Power supply voltage: AC200V/60A *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Coter" is a device that accurately applies a coating material to copper foil, aluminum foil, and films at a consistent thickness. The "Small Precision Coating Machine 2-Roll Coter" is a standard type of direct coater, featuring an exchangeable coating head. The roll width ranges from 200mm to 500mm (in 50mm increments), and the drying oven is 800mm x 1 unit (hot air type). There are many options available, and depending on your requirements, you can select the necessary options to provide the appropriate coating device. 【Specifications (partial)】 ■ Coating method: Direct coat ■ Coating head: Exchangeable structure ■ Roll width: 200mm to 500mm (in 50mm increments) ■ Drying oven: 800mm x 1 unit (hot air type) ■ Power supply voltage: AC200V/50A *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a small vacuum stirrer developed for LIB (Lithium-ion Battery). Available in 1-liter, 3-liter, and 6-liter types. The planetary blade has one unit with a revolution speed of up to 100 rpm and a rotation speed of up to 240 rpm, while the high-speed blade has one unit with a revolution speed of 10 to 100 rpm and a rotation speed of 300 to 3000 rpm. 【Specifications (partial)】 ■ 1-liter type ■ 3-liter type ■ 6-liter type ■ Options: jacket tank, hot water circulation (cold water circulation) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Sunk Metal, we buy and sell unused machinery. If your company is having trouble disposing of machinery other than battery prototype equipment, please feel free to contact us. *For more details, please check the link below or feel free to reach out to us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- In the electrode plate coating process, thickness measurements can be sampled as needed at any time. - The punching dies can accommodate sizes from Φ5 to Φ25 in increments of 0.01mm. - The standard type for the main body has a mold size ranging from Φ5 to Φ15.9, the large type ranges from Φ16 to Φ20, and the custom type ranges from Φ20.01 to Φ25. The standard type has a length of 50mm from the center of the punched hole to the insertion end face, but longer lengths can also be accommodated, with a maximum length of up to 200mm.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features - The size of the workpiece can be adjusted from 5 mm to 35 mm by changing the jig. - The front and rear bar heaters can be individually temperature controlled. - Temperature control of the bar heaters is managed through a digital setting device for both setting and display. It includes a safety device for over-temperature settings. - Additional safety measures include the installation of covers on high-temperature parts and a limit switch on the front cover. - Pressure can be adjusted using an air cylinder system with a regulator. - The pressurization time can be set.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Automatic Stacking Device" is a machine that automatically stacks a specified number of layers with high precision by cutting the positive and negative electrodes set in the stocker and the separator supplied in rolls to any desired length, alternating them. There are two types based on the method of sealing the separator: the 3-head type and the 4-head type. The "3-head type" alternates layers of separator + negative electrode + separator + positive electrode + separator, and finally spot welds the ends of the separator. The "4-head type" first sandwiches the positive electrode with the separator above and below, heat seals the separator into a bag shape, and then stacks the negative electrode on top. 【Features】 ■ A device that automatically stacks a specified number of layers with high precision in an alternating manner. ■ Available in two types: 3-head type and 4-head type. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Roll Press" is used by the coater to compress the applied composite material on the substrate to increase its density. This product has a standardized pressing force ranging from 1 ton to 50 tons. Depending on the pressing force, there are three types of pressing methods: mechanical, air-hydraulic, and hydraulic. Additionally, we offer a compact air-hydraulic heating roll press "R-THCH1516," designed for use even when a 200V power supply is not available at the installation site. 【Features】 ■ Used to compress the applied composite material on the substrate to increase its density ■ Standardized pressing force ranging from 1 ton to 50 tons ■ Three types of pressing methods: mechanical, air-hydraulic, and hydraulic *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Vacuum Liquid Injection Device" is a device that injects a set amount of electrolyte into cylindrical, rectangular, and laminated batteries under vacuum conditions. The device is standardized in several types depending on the battery type and size. The injection process is carried out separately, and there is also a vacuum sealing device that alternates between vacuum and atmospheric release to seal under vacuum conditions (VD110/VD1200). 【Features】 ■ A device that injects a set amount of electrolyte under vacuum conditions ■ The device is standardized in several types depending on the battery type and size ■ For cylindrical and rectangular types, the vacuum chamber is small, allowing for slight pressurization ■ The laminated type finishes with a shorter injection time compared to cylindrical and rectangular types *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "slitter" is a device that slits the plates that have been compressed with a roll press after being coated with a coater. Slitting can involve only slitting the uncoated sections at both ends, or slitting into several strips at both ends and a specified width. We also offer a slitting & cutting device that cuts to a specified length after slitting. 【Product Lineup】 ■ Roll-to-roll slitter ■ Slitter & cutter *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Coter" is a device that accurately applies a coating of a consistent thickness to copper foil, aluminum foil, and films. Our products offer three types of coating methods: comma head type, die head type, and gravure head type, depending on the application method. We have a wide range of options available, allowing you to select the necessary options based on your requirements, and we provide the appropriate coating device. 【Features】 ■ Product testing is possible ■ Three types of coating methods ■ Abundant options ■ The appropriate method can be selected based on the materials to be coated and the coating conditions ■ Choose the necessary options, and we will provide the suitable coating device *For more details, please refer to the materials. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document provides a clear explanation of the equipment used for battery prototyping, such as lithium-ion batteries, step by step. We encourage you to read it! 【Features of Our Equipment】 ■ Equipment for battery "prototyping" ■ Short delivery time (as short as 3 months) ■ Coating thickness can be adjusted in 1-micron increments ■ Customization is also possible! Please consult with us. ■ Prototyping is also possible in our rental lab We can also provide the necessary substrates. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This device can perform unstable coating tasks that were previously done manually at a constant speed, allowing for the reproducible production of a specified film thickness. In addition to the bar coater, applicators such as doctor blades and baker-type applicators can also be attached and used.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- The test (prototype) battery can set includes two types of cylindrical cans and one type of coin can. - At Sunk Metal, we have various equipment available to prototype sample batteries using these battery can sets. - If you do not have the necessary prototyping equipment in-house, please use our rental lab. - The rental lab is fully equipped with all the necessary facilities to manufacture prototype batteries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration