181~225 item / All 1735 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF181~225 item / All 1735 items

Filter by category

In the semiconductor manufacturing industry, precise dimensional control at each stage of the manufacturing process is required to improve product quality and yield. In particular, the accuracy of parallelism in the processing of wafers and substrates significantly affects product performance. If parallelism is not properly managed, it can lead to the occurrence of defects in the manufacturing process and deterioration of product performance. This video explains the basics of "parallelism," a type of geometric tolerance, and contributes to quality control in semiconductor manufacturing. [Application Scenarios] - Quality control in semiconductor manufacturing - Processing processes for wafers and substrates - Acquisition of basic knowledge regarding parallelism [Effects of Implementation] - Deepens understanding of parallelism and helps improve manufacturing processes. - Reduces the occurrence of defects and improves yield. - Contributes to the enhancement of product quality.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the medical device industry, precise manufacturing of parts is essential to ensure product reliability. Particularly in medical devices that require precise movements, the parallelism of parts significantly impacts product performance. Deficiencies in parallelism can lead to malfunctions or failures of the equipment. This video explains the basics of "parallelism," a type of geometric tolerance. It covers the definition of parallelism, examples of its use, how it is represented in drawings, and points to consider when using it. Please use this video as a reference to enhance the quality of medical devices. 【Application Scenarios】 - Quality control of parts in medical device manufacturing - Understanding parallelism indications during the design phase - Learning measurement methods in the manufacturing field 【Benefits of Implementation】 - Improved product reliability - Reduction of quality issues - Strengthened collaboration between design and manufacturing departments

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the machine tool industry, the machining accuracy that affects product quality is extremely important. In particular, if the parallelism of parts is not properly maintained, it can lead to assembly defects and performance degradation. This video explains the basics of "parallelism," which is a type of geometric tolerance. 【Application Scenarios】 * Design and manufacturing of machine tools * Engineers aiming to improve machining accuracy * Skill enhancement in reading drawings 【Benefits of Introduction】 * Understanding the definition and importance of parallelism * Learning how to interpret parallelism on drawings * Contributing to the improvement of machining accuracy

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the mold industry, dimensional stability is a crucial factor that affects product quality. Particularly in molds that require high precision, the accuracy of parallelism significantly impacts the finish and durability of the product. If parallelism is not properly managed, it can lead to dimensional errors in the product or early failure. This video explains the basics of "parallelism," a type of geometric tolerance, and deepens understanding in mold design and manufacturing. It covers the definition of parallelism, examples of its use, how it is represented in drawings, and points to be aware of. This video will be beneficial for mold designers, manufacturing engineers, and quality control personnel in improving the quality of mold production. 【Application Scenarios】 - Understanding drawings in mold design - Quality control during mold manufacturing - Manufacturing products that require dimensional accuracy 【Effects of Introduction】 - Deepening understanding of parallelism and improving quality in mold design and manufacturing - Reducing defective products and costs - Enhancing product reliability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the precision machinery industry, quality control is highly dependent on the accuracy of products. Parallelism is an essential factor in ensuring the precise assembly and operation of components, as even slight deviations can affect the overall performance of the product. A lack of understanding of parallelism can lead to the occurrence of defective products and a decline in product performance. This video explains the basics of "parallelism," a type of geometric tolerance. It covers the definition of parallelism, examples of its use, how it is represented in drawings, and points to consider when using it, so you can enhance your quality control. 【Application Scenarios】 - Quality control in the manufacturing process of precision machine parts - Understanding parallelism indications during the product design phase - Measuring parallelism in quality inspections 【Benefits of Introduction】 - Deepening understanding of parallelism and improving the accuracy of quality control - Reducing defective products and cutting costs - Enhancing product reliability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, the precise manufacturing and assembly of parts are essential for ensuring the safety of aircraft. Particularly for parts that require high precision, a correct understanding of parallelism and appropriate instructions are crucial. Deficiencies in parallelism can lead to malfunctioning parts or structural weaknesses, potentially resulting in serious accidents. This video explains the basics of "parallelism," a type of geometric tolerance. It covers the definition of parallelism, examples of its use, how it is represented in drawings, and points to consider when using it. By watching this video, you can deepen your understanding of parallelism and contribute to safe product design. [Application Scenarios] - Manufacturing of aircraft parts - Manufacturing of space rocket parts - Manufacturing of precision instruments [Effects of Implementation] - Improvement in part quality - Enhancement of product safety - Reduction of design errors

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, the assembly precision of parts greatly affects the quality and performance of products. Particularly in critical components such as engines and transmissions, even a slight deviation in parallelism can lead to performance degradation or the occurrence of abnormal noises. This video explains the basics of "parallelism," a type of geometric tolerance. By understanding the definition of parallelism, its usage examples, how it is represented on drawings, and points to consider when using it, you can contribute to improving quality in the design and manufacturing of automotive parts. 【Application Scenarios】 - Design of automotive parts - Quality control in manufacturing sites - Inspection of parts 【Effects of Introduction】 - Improvement of assembly precision of parts - Enhancement of product quality - Reduction of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the measurement equipment industry, accurate measurements are essential to ensure product quality. In particular, the precision of perpendicularity greatly affects the performance of the equipment. If the understanding of perpendicularity is insufficient, measurement errors may occur, leading to a decline in product quality. This video explains the basics of "perpendicularity," which is a type of geometric tolerance. 【Usage Scenarios】 - Manufacturing of measurement equipment - Utilization in quality control departments - Streamlining measurement operations 【Benefits of Implementation】 - Understanding the definition of perpendicularity and improving measurement accuracy - Understanding the indications of perpendicularity on drawings - Grasping points to note during measurements

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the 3D printing industry, the accuracy of the printed objects greatly affects the quality of the products. Particularly in additive manufacturing, precise alignment of each layer is crucial, and understanding perpendicularity is essential. If perpendicularity is not properly managed, dimensional errors and distortions in the printed objects may occur, potentially adversely affecting the functionality and appearance of the products. This video explains the basics of "perpendicularity," a type of geometric tolerance. It covers the definition of perpendicularity, how it is used in drawings, and points to consider when using it, supporting problem-solving in 3D printer manufacturing. 【Application Scenarios】 - When producing prototypes with a 3D printer - Manufacturing parts that require high precision in printed objects - When defects occur that differ from the design drawings 【Benefits of Implementation】 - Improvement in the quality of printed objects - Achieving prints as per the design - Reduction of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the robotics industry, precise assembly of products and stable operation are required. Particularly for robots that perform precise positioning and repetitive movements, the perpendicularity of components is crucial. Errors in perpendicularity can lead to malfunctioning of the robot and a decline in product quality. This video explains the basics of "perpendicularity," a type of geometric tolerance. 【Application Scenarios】 - Assembly of robotic arms - Manufacturing of precision equipment - Processes requiring positioning accuracy 【Benefits of Implementation】 - Improved operational accuracy of robots - Enhanced product quality - Reduction of defective products Matsui Manufacturing Co., Ltd. offers a consistent production system from hot forging to machining, pipe bending, brazing, and unit assembly, focusing on non-ferrous metals such as copper, brass, and aluminum. We propose suitable QCD (Quality, Cost, Delivery) solutions to our customers from our production bases located in four locations (Osaka, Tottori, Himeji, and China).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, precise manufacturing of components is essential to ensure product reliability. In particular, the accuracy of perpendicularity significantly affects the assembly precision and performance of products. If perpendicularity is not properly managed, it can lead to component distortion or poor contact, potentially resulting in product failure or performance degradation. This video explains the basics of "perpendicularity," a type of geometric tolerance. It covers the definition of perpendicularity, examples of its use, how it is represented in drawings, and points to consider when using it, contributing to the improvement of quality in electronic devices. 【Application Scenarios】 - Design and manufacturing departments of electronic devices - Quality control departments - Procurement departments for components 【Benefits of Implementation】 - Deepen understanding of perpendicularity and improve quality in design and manufacturing - Contribute to enhancing product reliability - Reduce defective products and cut costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the machine tool industry, there is a demand for high precision in products. In particular, the assembly precision and machining precision of parts are crucial factors that influence the overall performance of the product. A lack of understanding of perpendicularity can lead to a decrease in these precisions, potentially resulting in defective products and performance degradation. This video explains the basics of "perpendicularity," which is a type of geometric tolerance. 【Application Scenarios】 - Design and manufacturing of machine tools - Quality control in parts processing - Improvement of drawing comprehension 【Effects of Introduction】 - Deepening understanding of perpendicularity and improving design and manufacturing precision - Reduction of defective products and cost savings - Improvement of product quality and customer satisfaction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the semiconductor industry, high precision is required in microfabrication. In particular, even slight deviations in perpendicularity can significantly affect product performance. Understanding perpendicularity is crucial in quality control. This video explains the basics of "perpendicularity," which is a type of geometric tolerance. 【Application Scenarios】 * Reading drawings in microfabrication * Understanding measurement methods in quality control * Troubleshooting in manufacturing sites 【Effects of Introduction】 * Improvement in knowledge regarding perpendicularity * Enhancement of quality control capabilities * Reduction in the rate of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the medical device industry, accurate dimensions and shapes of components are essential to ensure product safety and reliability. Particularly in medical devices that require precise assembly, the perpendicularity of components significantly affects product performance. Errors in perpendicularity can lead to equipment malfunctions and risks to patients. This video explains the basics of "perpendicularity," one of the geometric tolerances, and supports problem-solving in medical device design and manufacturing. 【Usage Scenarios】 - Design phase of medical devices - Quality control in the manufacturing process - Incoming inspection of components 【Benefits of Implementation】 - Deepening understanding of perpendicularity, leading to improved design and manufacturing quality - Enhanced ability to read technical drawings - Cost reduction through the reduction of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the precision machinery industry, understanding geometric tolerances is essential for maintaining product accuracy and reliability. In particular, perpendicularity greatly affects the assembly accuracy of parts and influences product performance. Understanding the definition of perpendicularity and its application in drawings is important for quality management of products. This video clearly explains the basics of perpendicularity and contributes to maintaining the performance of precision machinery. 【Usage Scenarios】 - Design and manufacturing of precision machinery - Education in quality control departments - Engineers aiming to improve product accuracy 【Benefits of Introduction】 - Deepening understanding of perpendicularity and improving design and manufacturing accuracy - Enhancing product quality and reducing defect rates - Skill enhancement for engineers

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the mold industry, understanding perpendicularity is essential to guarantee the dimensional accuracy of products. If the perpendicularity of a mold is inaccurate, it can lead to dimensional defects in molded products or assembly issues, potentially resulting in a decline in product quality. This video explains the basics of "perpendicularity," a type of geometric tolerance, including its definition, examples of use, how it is represented in drawings, and precautions for use. By deepening the understanding of perpendicularity, we contribute to quality improvement in mold design and manufacturing. 【Application Scenarios】 - Creating drawings during the mold design phase - Dimensional management during mold production - Quality inspection of molded products 【Benefits of Implementation】 - Acquisition of knowledge regarding perpendicularity - Improvement of quality in mold design and manufacturing - Reduction of defective products and cost savings

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the machinery manufacturing industry, product quality and cost management are important issues. In particular, the precision of parts greatly affects product performance and durability, potentially leading to an increase in defective products and rework. Understanding geometric tolerances, especially perpendicularity, enhances the accuracy of drawing interpretation, reduces waste in the manufacturing process, and contributes to cost reduction. This video explains the definition of perpendicularity, examples of its use, how it is applied in drawings, and points to be aware of, supporting problem-solving in design and manufacturing. 【Usage Scenarios】 - Design and manufacturing of machine parts - Education in quality control departments - Companies aiming for cost reduction 【Effects of Implementation】 - Improved drawing interpretation skills - Increased efficiency in manufacturing processes - Reduction of defective products - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, the precise manufacturing of parts is essential to ensure the safety and performance of products. Particularly in components such as aircraft parts, even a slight deviation in perpendicularity can significantly impact overall functionality. This video explains the basics of "perpendicularity," a type of geometric tolerance. It covers the definition of perpendicularity, examples of its use, how it is represented in drawings, and points to consider when using it, supporting the resolution of quality management challenges in the aerospace field. 【Application Scenarios】 - Manufacturing of aircraft parts - Manufacturing of space development-related components - Manufacturing of precision instruments 【Benefits of Implementation】 - Deepening understanding of perpendicularity and improving design and manufacturing quality - Enhancing drawing interpretation skills - Early detection of issues in quality management

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, precise manufacturing of parts is essential for quality control. In particular, perpendicularity significantly affects the assembly accuracy of components and is a crucial factor that influences the performance and safety of the product. A lack of understanding of perpendicularity can lead to defects in parts and assembly errors, potentially resulting in a decline in the quality of the final product. This video explains the basics of "perpendicularity," a type of geometric tolerance, and supports problem-solving in quality management of automotive parts. 【Usage Scenarios】 - Design and manufacturing departments of automotive parts - Quality control personnel - Engineers on the manufacturing floor 【Benefits of Introduction】 - Understanding the definition and importance of perpendicularity - Improved ability to interpret perpendicularity on drawings - Early detection of issues in quality management - Enhanced quality of parts and increased reliability of products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the energy industry, particularly in the manufacturing and maintenance of pipelines, dimensional accuracy is crucial. If the roundness of the pipes is not properly managed, it can lead to leaks at the joints and a decrease in strength, potentially affecting the safety of energy supply. This video explains the definition of roundness, examples of its use, how it is represented in drawings, and precautions for its use. Please utilize this for pipe quality management. 【Usage Scenarios】 - Pipeline manufacturing - Pipe quality management - Drawing creation 【Benefits of Implementation】 - Improved pipe quality - Increased product reliability - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the optical equipment industry, the quality of precision components such as lenses and barrels greatly affects product performance. In particular, understanding cylindricality and providing appropriate specifications are crucial for ensuring optical axis accuracy. Misunderstanding or improper specifications of cylindricality can lead to decreased optical performance and assembly defects. This video explains the basics of "cylindricality," which is a type of geometric tolerance. 【Usage Scenarios】 - Design of optical lenses - Manufacturing of barrels - Calibration of measuring instruments 【Benefits of Introduction】 - You will understand the definition of cylindricality and be able to provide appropriate specifications on drawings. - It will contribute to the improvement of optical component quality. - It will lead to increased product reliability.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the watch industry, the precision of gears is a crucial factor that affects the quality of the product. In particular, the roundness of gears is essential for ensuring smooth operation and durability. Deficiencies in roundness can lead to gear wear, unusual noises, and even failure of the entire product. This video explains the basics of "roundness," a type of geometric tolerance. 【Application Scenarios】 * Gear design * Gear manufacturing * Quality control 【Benefits of Implementation】 * Improvement in gear quality * Increased product reliability * Reduction of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the home appliance industry, the performance of motors is a crucial factor that influences product quality. To ensure the smooth operation of motors, the precision of components is essential, and among these, cylindricity is a key element. Understanding cylindricity leads to a reduction in defective products and an improvement in product lifespan in the design, manufacturing, and quality control of motors. This video explains the definition of cylindricity, examples of its use, and measurement methods, addressing your questions. 【Application Scenarios】 - Design of motor components - Evaluation of cylindricity in quality control - Interpretation of drawings 【Benefits of Introduction】 - Deepening understanding of cylindricity to enhance design quality - Reduction of defective products and cost savings - Improvement of product reliability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the robotics industry, precise joint movement is required. Particularly in joints that undergo repetitive motions or are subjected to high loads, smooth movement and high durability are essential. A lack of understanding of cylindricity can lead to joint play and premature wear. This video explains the basics of "cylindricity," a type of geometric tolerance. 【Application Scenarios】 - Design of robotic joints - Manufacturing of precision instruments - Quality control 【Benefits of Introduction】 - Understand the definition of cylindricity - Learn how to interpret cylindricity on drawings - Understand the points to be cautious about when indicating cylindricity

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the semiconductor manufacturing industry, particularly in wafer production, high precision is required. Cylindricity is one of the important factors that influence the quality of the wafer manufacturing process. Understanding cylindricity contributes to ensuring the shape accuracy of the wafer and improving yield. This video explains the definition of cylindricity, examples of its use, how it is represented in drawings, measurement methods, and points to note. 【Usage Scenarios】 - Shape accuracy management in wafer manufacturing - Quality improvement in semiconductor manufacturing processes - Acquisition of basic knowledge about cylindricity 【Effects of Introduction】 - Promotion of understanding quality issues in wafer manufacturing - Streamlining operations through the acquisition of knowledge about cylindricity - Skill enhancement for semiconductor manufacturing engineers

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the mold industry, the precision of the mold shape is crucial to ensure product accuracy. In particular, the precision of cylindrical shapes, which affects the quality of molded products, is an important factor in the design and manufacturing of molds. A lack of understanding of cylindricity can lead to molding defects and a decrease in product accuracy. This video explains the basics of "cylindricity," which is a type of geometric tolerance. 【Application Scenarios】 - Mold design - Mold manufacturing - Quality control of molded products 【Benefits of Implementation】 - Deepening the understanding of cylindricity to improve the precision of mold design and manufacturing - Reducing molding defects - Stabilizing product quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the precision machinery industry, especially in lens manufacturing, high accuracy is required. The performance of a lens is crucially dependent on its shape accuracy, particularly cylindricality. Understanding cylindricality is essential for providing appropriate instructions during the design phase and for quality control during the manufacturing process. By understanding the definition of cylindricality, how it is used in drawings, and the points to be aware of, the performance of the lens can be maximized. 【Application Scenes】 - Lens designers - Engineers involved in lens manufacturing - Quality control personnel 【Benefits of Implementation】 - Improved drawing interpretation skills - Early detection of quality issues - Enhanced product accuracy

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the machine tool industry, the high precision operation of spindles is a crucial factor that affects processing quality. If the cylindricity of the spindle is not properly managed, it can lead to a decrease in processing accuracy, resulting in defective products or machine failures. This video explains the basics of "cylindricity," a type of geometric tolerance, and provides information useful for managing spindle precision. 【Usage Scenarios】 - Design and manufacturing of spindles - Maintenance of spindles - Quality control of machine tools 【Benefits of Implementation】 - Improvement in spindle precision - Enhancement of processing quality - Reduction of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, particularly in turbine design, the precision of components significantly affects performance and safety. Cylindricity is crucial for ensuring the accurate shape of the turbine's rotational axis and other important parts. A lack of understanding of cylindricity can lead to premature wear of components, performance degradation, and in the worst case, serious accidents. This video will explain the definition of cylindricity, examples of its use, how it is represented in drawings, and important considerations. 【Application Scenarios】 - Design of turbine components - Quality control - Education in manufacturing settings 【Benefits of Implementation】 - Deepening understanding of cylindricity and improving design quality - Enhancing the accuracy of quality control in manufacturing processes - Streamlining the education of engineers

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the design and manufacturing of automobile engines, the precision of parts is a crucial factor that affects performance and reliability. Particularly for parts with cylindrical shapes inside the engine (such as cylinders and pistons), accurate management of cylindricity is required. If cylindricity is not properly managed, it can lead to increased friction between parts, decreased sealing capability, the occurrence of abnormal noises, and ultimately result in reduced engine performance or failure. This video explains the basics of "cylindricity," which is a type of geometric tolerance. 【Application Scenarios】 - Design and manufacturing of engine parts - Education in quality control departments - Training for engineers 【Benefits of Implementation】 - Deepening understanding of cylindricity and improving quality in design and manufacturing - Enhancing drawing interpretation skills - Early detection of issues in quality control

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

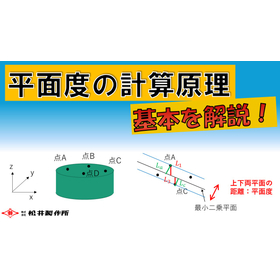

In the 3D printing industry, the accuracy of the printed objects greatly affects the quality of the products. In particular, poor flatness can lead to problems in assembly and functionality. In this video, I would like to outline the calculation method for "flatness," which is a type of geometric tolerance. Understanding the significance of flatness calculations will help in quality management of printed objects. 【Application Scenarios】 * Quality management of 3D printed objects * Consideration of printing accuracy during the design phase * Inspection processes after printing 【Benefits of Implementation】 * Improvement in the quality of printed objects * Reduction of defective products * Strengthening collaboration between design and manufacturing

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the robotics industry, high-precision positioning is required. Particularly in the assembly and processing of parts, the accuracy of flatness becomes a crucial factor that influences product quality. If the flatness is not appropriate, misalignment can occur in the movements of the robotic arm, potentially leading to assembly defects and decreased processing accuracy. In this video, I would like to outline the calculation method for "flatness," which is a type of geometric tolerance. Through this video, I hope you gain a deeper understanding of the significance of flatness calculations and find it useful for improving positioning accuracy. 【Application Scenes】 * Precise positioning of robotic arms * Quality control in the parts assembly process * Improvement of processing accuracy 【Effects of Implementation】 * Enhanced positioning accuracy * Stabilization of product quality * Increased efficiency of processes

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the optical industry, optical path control is essential to ensure the accurate propagation of light. Flatness is a crucial factor that affects the performance of optical components and directly influences the precision of light reflection and refraction. Understanding how to calculate flatness is vital for optimizing performance in the design of optical systems. 【Application Scenarios】 - Design of optical lenses and mirrors - Construction of fiber optic systems - Manufacturing of precision measurement instruments 【Benefits of Implementation】 - Improved performance of optical components - Enhanced accuracy of optical path control - Increased product quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, accurate manufacturing of components is essential to ensure product reliability. In particular, the flatness of items such as circuit boards and enclosures greatly affects product performance and durability. Understanding the calculation methods for flatness is helpful for quality control during the design phase and for identifying issues in the manufacturing process, leading to improved product reliability. This video explains the principles of flatness calculation and contributes to enhancing the reliability of electronic devices. 【Usage Scenarios】 - Quality control in the design and manufacturing of electronic devices - Measurement of flatness for circuit boards and enclosures - Evaluation of product reliability 【Benefits of Implementation】 - Improvement in product quality - Reduction of defective products - Increased customer satisfaction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the machine tool industry, high precision is required, and understanding flatness, which affects product quality, is crucial. Understanding the calculation method for flatness is essential for maximizing the performance of machine tools and achieving high-precision machining. This video provides an overview of the calculation method for flatness and contributes to improving the performance of machine tools. 【Usage Scenarios】 * Design and manufacturing of machine tools * Inspections in quality control departments * Improvement of machining accuracy 【Effects of Implementation】 * Promotion of understanding the calculation method for flatness * Improvement of machine tool performance * Enhancement of product quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the precision measurement industry, especially in calibration work, the accuracy of measurement results is essential. Understanding flatness is crucial for ensuring the reliability of measurement results. By understanding the calculation methods for flatness, one can appropriately carry out the calibration of measuring instruments and evaluate measurement results, leading to improvements in quality control. This video clearly explains the principles of flatness calculation and supports the efficiency of calibration work. 【Usage Scenarios】 * Calibration of precision measuring instruments * Evaluation of measurement results in quality control * Inspection work in manufacturing sites 【Benefits of Implementation】 * Improved reliability of measurement results * Increased efficiency of calibration work * Enhanced level of quality control

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the medical device industry, precise manufacturing of components is required to ensure product safety. Particularly in medical devices that require precise assembly, the flatness of components becomes a crucial factor that influences the product's performance and safety. Understanding the calculation of flatness is essential for quality control of components. This video provides an overview of the method for calculating flatness and is structured to help deepen the understanding of its significance. 【Application Scenarios】 - Quality control in the manufacturing of medical device components - Precision evaluation of components during the design phase - Early detection of issues in the manufacturing process 【Benefits of Introduction】 - Improvement in component quality - Enhancement of product safety - Reduction of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the mold industry, the precision of molds, which affects product quality, is crucial. Particularly for molds that require high precision, an accurate understanding and calculation of flatness is essential. If the calculation of flatness is inaccurate, it can impact the dimensional accuracy of the product, potentially leading to defects and decreased performance. This video provides an overview of the method for calculating flatness and contributes to improving the precision of mold manufacturing. 【Usage Scenarios】 - High-precision mold manufacturing - Mold quality management - Mold design 【Benefits of Implementation】 - Deepen understanding of flatness calculations - Improve precision in mold manufacturing - Reduce defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry's quality management, ensuring product precision is essential for securing safety and reliability. In particular, the flatness of parts significantly affects assembly accuracy and functionality. Understanding the calculation method for flatness is important for quality management personnel to evaluate product quality and implement improvements. In this video, I would like to outline the calculation method for "flatness," which is a type of geometric tolerance. 【Usage Scenarios】 - Quality management in the manufacturing process of automotive parts - Flatness evaluation during the design phase of parts - Training for quality management personnel 【Benefits of Introduction】 - Improvement in part quality - Reduction of defective products - Skill enhancement for quality management personnel

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the semiconductor industry, high precision is required in fine processing. Flatness is one of the important factors in evaluating processing accuracy. Understanding the calculation method for flatness is essential for improving processing quality. In this video, I would like to outline the calculation method for "flatness," which is a type of geometric tolerance. Rather than following specific formulas, I aimed to explain the "meaning of the formulas" and what goals are pursued in the calculations. I hope this video helps you gain a deeper understanding of the significance of flatness calculations. 【Application Scenarios】 * Fine processing processes in semiconductor manufacturing * Quality control of parts requiring flatness measurement * Education of processing engineers 【Benefits of Introduction】 * Improvement of processing accuracy * Reduction of defective products * Enhancement of quality control capabilities

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, reducing the weight of components is essential for improving performance and reducing costs. Flatness is a crucial factor that determines the precision of components, and understanding flatness is vital in lightweight design to maintain the strength of parts while minimizing unnecessary materials. This video provides an overview of how to calculate flatness and supports problem-solving in lightweight design. 【Application Scenarios】 * Design of aircraft components * Design of spacecraft components * Design of structures requiring weight reduction 【Benefits of Implementation】 * Contributes to weight reduction of components * Enhances design efficiency * Reduces costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the mechanical manufacturing industry, a precise understanding of geometric tolerances is required to ensure product quality. In particular, flatness significantly affects the accuracy of components and directly relates to product assembly and performance. Understanding the calculation method for flatness is essential for quality management of products. This video outlines the calculation method for flatness and contributes to improving quality management by understanding the significance of the calculations. 【Application Scenarios】 * Quality management in the manufacturing of mechanical parts * Tolerance setting in product design * Measurement and inspection in manufacturing sites 【Effects of Introduction】 * Promotion of understanding the calculation method for flatness * Improvement of quality management capabilities * Enhancement of product accuracy

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, the quality of the circuit board significantly affects the performance of the product. In particular, ensuring the accuracy of electronic component placement and the reliability of connections requires the straightness of the circuit board to be maintained. Poor straightness can lead to component placement defects or connection failures, potentially resulting in product malfunctions. This video explains the measurement method for "straightness," a type of geometric tolerance, and supports quality improvement in circuit board design and manufacturing. 【Usage Scenarios】 * Straightness management in circuit board design * Inspection during the circuit board manufacturing process * Utilization in quality control departments 【Benefits of Implementation】 * Improved quality of circuit boards * Enhanced product reliability * Reduction of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the optical equipment industry, particularly in lens manufacturing, the precision of lenses significantly affects the performance of the products. The straightness of the lens influences light refraction and image distortion, making it a crucial factor in product quality. Measuring straightness is essential to ensure that the lens performs as intended in its design. This video explains the measurement method for "straightness," a type of geometric tolerance. 【Application Scenarios】 - Measuring straightness in the lens processing stage - Confirming the axis in the lens assembly stage - Quality control of optical equipment 【Benefits of Implementation】 - Improved lens quality - Reduction of defective products - Increased efficiency in the inspection process

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the watch industry, particularly in the manufacturing of gears, high precision is required. The precise positional relationship of each point on the circumference of the gear directly affects the accuracy of the watch, and even slight errors can lead to malfunctions. Roundness is one of the critical factors that influence the performance of gears. This video will explain the definition of roundness, how it is used in drawings, and points to be aware of when using it. By understanding roundness, we can contribute to improving the quality in the design and manufacturing of gears. 【Usage Scenarios】 - Design phase of gears - Quality control in the manufacturing process of gears - Acquisition of basic knowledge regarding roundness 【Effects of Introduction】 - Improvement in gear quality - Reduction of defective products - Streamlining of design and manufacturing processes

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration