1~45 item / All 51 items

Displayed results

Filter by category

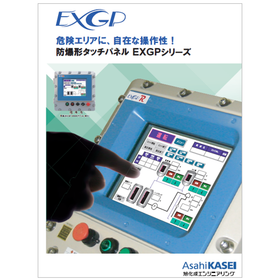

防爆製品

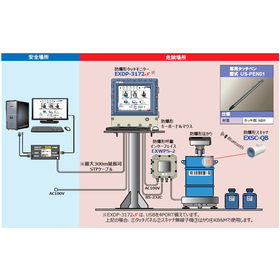

旭化成エンジニアリングは多様な防爆製品の開発・販売を行っております。導入前のご支援から保守(オンサイト修理)まで、経験豊富な技術者が一貫してご対応します。 製品ラインアップには防爆形タッチパネル、防爆形シンクライアント、防爆形無線アクセスポイントなどをご用意しております。