46~84 item / All 84 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registrationContact this company

Contact Us Online46~84 item / All 84 items

Filter by category

In the infrastructure industry, continuous monitoring is required to maintain the integrity of structures such as bridges and tunnels. In particular, vibrations are an important indicator of deterioration or abnormalities in structures. Nearline-PM enables quantitative and objective management of infrastructure equipment's vibrations through wireless vibration sensors, allowing for early detection of anomalies. It does not require wiring and is easy to retrofit, making it simple to implement in existing facilities. 【Usage Scenarios】 - Bridges - Tunnels - Plant equipment 【Benefits of Implementation】 - Early detection of equipment abnormalities, reducing repair costs - Enables planned maintenance, contributing to the longevity of equipment - Improves the efficiency of inspection work through remote monitoring

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the energy industry's equipment maintenance, stable operation of plants is crucial. In particular, failures of rotating machines such as motors, pumps, fans, and compressors can lead to losses due to operational downtime and decreased safety. Nearline-PM continuously monitors the vibrations of these facilities, enabling early detection of failure signs and allowing for planned maintenance. This contributes to stable operation of equipment and reduction of maintenance costs. 【Usage Scenarios】 - Power plants - Substations - Oil plants - Gas plants 【Benefits of Implementation】 - Reduced risk of unexpected equipment shutdowns - Lower maintenance costs - Extended equipment lifespan

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the manufacturing industry, production stoppages due to equipment failures can lead to significant losses. In particular, abnormalities in rotating equipment such as motors, pumps, and fans require early detection. Nearline-PM continuously monitors the vibrations of these machines, capturing signs of potential failures and enabling planned maintenance. This reduces the risk of unexpected breakdowns and supports stable operations. 【Application Scenarios】 - Rotating equipment such as motors, pumps, fans, and compressors - Abnormality detection in bearings - Predictive maintenance of equipment 【Benefits of Implementation】 - Reduction in maintenance costs - Prevention of unexpected failures - Improved equipment condition monitoring and efficiency on-site

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In a data center, the stable operation of servers is the most important issue. Abnormal vibrations from server cooling fans and power units can lead to system shutdowns. Nearline-PM continuously monitors the vibrations of these devices and detects abnormalities early, preventing downtime before it occurs. 【Usage Scenarios】 - Server rooms - Cooling fans and power units in data centers - 24/7 operational monitoring 【Benefits of Implementation】 - Stable operation of servers - Reduced risk of system shutdowns - Lower operational costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the tunnel industry, rapid information transmission during accidents and disasters is essential. Especially since communication environments are limited within tunnels, securing reliable means of contact becomes crucial. Wireless communication enables quick information transfer even in locations where laying wired cables is difficult. The explosion-proof access point 'EXAP-200S' establishes a wireless LAN environment within tunnels, ensuring communication means during emergencies. 【Usage Scenarios】 - Emergency communication within tunnels - Communication among workers - Transmission of surveillance camera footage 【Benefits of Implementation】 - Minimization of damage through rapid information transmission - Ensuring the safety of workers - Efficient site management

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the port industry, especially in the handling of hazardous materials during inbound and outbound operations, safety management and efficient operations are essential. Wireless communication in hazardous material handling areas contributes to ensuring worker safety and speeding up operations, but explosion-proof performance is required. An inappropriate wireless environment can increase the risk of accidents. Our explosion-proof access point 'EXAP-200S' enables a wireless LAN environment within hazardous material manufacturing sites, contributing to the efficiency and safety of inbound and outbound operations. 【Usage Scenarios】 - Management of inbound and outbound operations in hazardous material handling areas - Wireless implementation of inventory management systems - Information sharing via mobile devices for workers 【Benefits of Implementation】 - Establishment of a wireless LAN environment in hazardous material handling areas - Increased efficiency of inbound and outbound operations - Enhanced safety for workers

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the warehouse industry, especially in warehouses handling hazardous materials, there is a demand for both the efficiency of inventory management and safety. Establishing a wireless LAN environment enables real-time inventory information tracking and improves work efficiency. However, in warehouses that handle hazardous materials, wireless LAN access points with explosion-proof performance are essential. The EXAP-200S realizes wireless communication within hazardous material manufacturing sites and contributes to the efficiency of inventory management. 【Usage Scenarios】 - Building an inventory management system within hazardous material warehouses - Managing inbound and outbound logistics using forklifts and handheld terminals - Visualizing real-time inventory information 【Benefits of Implementation】 - Improved accuracy of inventory management - Reduced work time - Enhanced safety - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the painting industry, process management through visualization is required. Particularly in environments using highly flammable paints, establishing a safe wireless communication environment is crucial. In the absence of a wireless LAN environment, wiring work becomes necessary, leading to increased costs. Additionally, it can be challenging to grasp the progress of the painting process in real-time, potentially resulting in decreased productivity. The explosion-proof access point 'EXAP-200S' enables a wireless LAN environment within hazardous material manufacturing sites and supports the visualization of the painting process. 【Usage Scenarios】 - Visualization of work progress within the painting booth - Remote monitoring of painting equipment operation status - Wireless collection of quality inspection data 【Benefits of Implementation】 - Increased productivity through the visualization of the painting process - Ensured safety for workers - Improved efficiency in data collection - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the shipbuilding industry, there are many tasks performed in areas where flammable materials are used, such as welding and painting, making explosion-proof performance essential for the introduction of wireless communication. To improve work efficiency, the establishment of a wireless LAN environment is required, but it is important to create a communication environment while ensuring safety. The EXAP-200S is equipped with explosion-proof performance, enabling a wireless LAN environment in hazardous areas. [Usage Scenarios] - Remote monitoring in welding areas - Quality control in painting areas - Location tracking in material management [Benefits of Implementation] - Ensuring worker safety - Reducing work time - Accelerating information sharing

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In equipment inspections at power plants, ensuring safety and efficient operations is essential. Particularly in inspection work within hazardous areas, remote operation and data collection via wireless communication are indispensable. However, conventional wireless LAN environments have been limited in their use within hazardous areas due to insufficient explosion-proof performance. The EXAP-200S is equipped with explosion-proof capabilities, allowing for the establishment of a wireless LAN environment even in hazardous areas within power plants. 【Use Cases】 - Equipment inspections within power plants - Wireless data collection in hazardous areas - Remote operation 【Benefits of Implementation】 - Improved work efficiency through wireless operations in hazardous areas - Enhanced safety - Streamlined data collection

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the food industry, temperature management in the manufacturing process is essential to ensure product quality and safety. Particularly in factories that handle temperature-sensitive foods, real-time monitoring and recording of temperature data is required. In the absence of a wireless LAN environment, collecting data from temperature sensors can be cumbersome, potentially delaying responses in the event of abnormalities. The explosion-proof access point 'EXAP-200S' enables the establishment of a wireless LAN environment even within hazardous material manufacturing sites, facilitating the implementation of temperature management systems. 【Usage Scenarios】 - Temperature management areas in food manufacturing factories - Refrigerated and frozen warehouses - Manufacturing processes handling hazardous materials 【Benefits of Implementation】 - Improved quality control through real-time monitoring of temperature data - Rapid response in the event of abnormalities - Enhanced work efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the mining industry, accurate location information is essential for ensuring worker safety and improving operational efficiency. Establishing a wireless communication environment is a challenge when working in hazardous areas. Wireless access points with explosion-proof performance are required to build a location information system in such environments. The EXAP-200S enables the realization of a wireless network even within hazardous material manufacturing sites, allowing for safety management based on location information. 【Usage Scenarios】 - Real-time location tracking of workers within the mine - Tracking of vehicles and equipment in hazardous areas - Rapid response in emergencies 【Benefits of Implementation】 - Improved safety for workers - Enhanced operational efficiency - Quick response in the event of an accident

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In chemical plant process management, data collection and real-time information sharing in a safe environment are essential. Particularly in manufacturing facilities that handle hazardous materials, there are many locations where the installation of wired LAN is difficult, necessitating the use of wireless technology. The EXAP-200S, equipped with explosion-proof performance, can establish a wireless LAN environment even within hazardous material manufacturing sites. This enables the safe and efficient collection, monitoring, and control of data necessary for process management. 【Usage Scenarios】 - Data collection from various sensors in hazardous material manufacturing facilities - Remote monitoring of production lines - Information sharing via mobile devices by workers 【Benefits of Implementation】 - Real-time data access from anywhere within the plant - Improved work efficiency and rapid response in case of abnormalities - Enhanced safety and compliance with regulations

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the gas industry, safety management within manufacturing facilities that handle hazardous materials is the most critical issue. To prevent accidents, remote monitoring and data collection using wireless networks are required. However, in areas where flammable gases are present, the introduction of wireless LANs has been restricted due to the risk of ignition. The EXAP-200S adopts an explosion-proof structure, enabling the use of wireless LANs in hazardous locations Zone 1 and Zone 2. 【Usage Scenarios】 - Remote monitoring within hazardous material manufacturing facilities - Wireless gas leak detection systems - Safety management of workers 【Benefits of Implementation】 - Enhanced safety management through the use of wireless LANs in hazardous locations - Cost reduction by minimizing wiring work - Early detection of anomalies through real-time data collection

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the oil plant industry, remote monitoring systems are essential for the safe operation and efficient management of plants. Particularly in manufacturing facilities that handle hazardous materials, laying wired LAN can be difficult in certain areas, and wiring in places with many moving parts can increase costs, worsen workability, and even heighten the risk of explosions. The EXAP-200S, equipped with explosion-proof performance, addresses these challenges by establishing a wireless LAN environment. 【Usage Scenarios】 - Installation of remote monitoring cameras in hazardous material manufacturing facilities - Data collection from various sensors within the plant - Monitoring of equipment with many moving parts 【Benefits of Implementation】 - Reduction in wiring construction costs - Establishment of a flexible monitoring system - Improvement in plant safety

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The electrical systems in hospitals are extremely important for supporting the stable operation of medical equipment and ensuring patient safety. Power outages can lead to interruptions in medical procedures and equipment failures, increasing the risk to patients' lives. Insulation deterioration of high-voltage cables is one of the causes of power outages, making regular diagnostics for early detection and countermeasures essential. LINDA measures the insulation condition of high-voltage cables under live conditions, allowing for the identification of deterioration trends to prevent unexpected accidents and contribute to the continuity of medical services. 【Usage Scenarios】 - Hospital electrical rooms - Insulation diagnostics of high-voltage cables - Stable operation of medical equipment - Reduction of power outage risks 【Benefits of Implementation】 - Continuity of medical services - Ensuring patient safety - Stable operation of electrical systems - Prevention of unexpected accidents

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the petrochemical plant industry, the reliability of high-voltage cables affects the overall safety of the plant. Insulation degradation of cables poses a risk of serious accidents such as power outages and fires, making early detection through regular diagnostics essential. LINDA measures the insulation condition of high-voltage cables while they are live, allowing for the identification of degradation trends and preventing unexpected accidents. 【Usage Scenarios】 - High-voltage cables in petrochemical plants - During regular inspections of the plant - Companies that prioritize safety 【Benefits of Implementation】 - Prevent accidents caused by cable insulation degradation - Contribute to stable plant operations - Enable planned maintenance through regular diagnostics

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In university research facilities, the safe operation of high-voltage cables that support experimental equipment and research activities is essential. Power outages can lead to interruptions in research, resulting in the loss of valuable data and delays in experiments. LINDA measures the insulation degradation of high-voltage cables while they are live, preventing unexpected accidents before they occur. This ensures the continuity of research activities and maintains a safe environment. 【Usage Scenarios】 - University research facilities - Experimental equipment using high-voltage cables - Situations where avoiding research interruptions due to power outages is desired 【Benefits of Implementation】 - Early detection of insulation degradation in high-voltage cables - Reduced risk of unexpected accidents - Ensured continuity of research activities - Maintenance of a safe research environment

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the water supply and drainage industry, a stable water supply is essential for supporting the lives of citizens. The deterioration of insulation in high-voltage cables can lead to power outages and potentially halt the functions of the water supply and drainage systems, which are critical lifelines. In particular, cables buried underground are difficult to assess for deterioration, making proactive measures crucial. LINDA conducts insulation diagnostics on high-voltage cables while they are live, allowing for the assessment of cable deterioration and the prevention of unexpected accidents. This contributes to the stable operation of water supply and drainage systems. 【Usage Scenarios】 - Insulation diagnostics of high-voltage cables in water supply and drainage facilities - Assessment of the deterioration of aging cables - Development of regular maintenance plans 【Benefits of Implementation】 - Reduced risk of power outages - Stable operation of equipment - Optimization of maintenance costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the steel industry, stable operation of equipment is essential, and operational shutdowns can lead to significant losses. The deterioration of insulation in high-voltage cables is one of the main causes of unexpected power outages, which hinder continuous operations. LINDA measures the insulation condition of high-voltage cables while they are live, allowing for early detection of signs of deterioration, enabling planned maintenance, and reducing the risk of operational shutdowns. 【Usage Scenarios】 - High-voltage distribution lines in steel mills - Regular inspections of equipment - Prevention of unexpected accidents 【Benefits of Implementation】 - Reduced risk of operational shutdowns through planned maintenance - Extended equipment lifespan - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the power industry, ensuring the reliability of high-voltage cables is essential for stable power supply. The deterioration of cable insulation poses a significant risk that can lead to power outages or accidents. LINDA measures the insulation of high-voltage cables under live conditions to understand the trends of deterioration, thereby preventing unexpected accidents and contributing to the stabilization of power supply. 【Usage Scenarios】 - Stabilization of power supply - Diagnosis of insulation deterioration in high-voltage cables - Maintenance of special high-voltage receiving equipment 【Benefits of Implementation】 - Reduction of power outage risks - Prolonging the lifespan of equipment - Optimization of maintenance costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In data centers, stable operation 24/7 is essential, and the reliability of power equipment is the most critical issue. The insulation deterioration of high-voltage cables can cause power outages and equipment failures, potentially having serious impacts on data center operations. LINDA measures the insulation condition of high-voltage cables while they are live, allowing for the early detection of signs of deterioration and preventing unexpected accidents. This supports the stable operation of data centers and ensures business continuity. 【Usage Scenarios】 - Power cables in data centers - High-voltage power receiving equipment - Regular maintenance of power equipment 【Benefits of Implementation】 - Reduced risk of power outages - Extended lifespan of equipment - Lower operational costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At airports, a stable power supply is essential to ensure the operation of aircraft and the safety of passengers. Power outages can cause delays in operations and the shutdown of facilities, potentially leading to significant losses. Deterioration of the insulation of high-voltage cables is one of the causes of power outages. LINDA measures the insulation condition of high-voltage cables under live conditions and detects signs of deterioration early, thereby reducing the risk of power outages. 【Usage Scenarios】 - Airport terminal buildings - Runway lighting - Air traffic control systems - Baggage handling systems 【Benefits of Implementation】 - Minimizing the impact of power outages on operations - Improving safety through stable equipment operation - Reducing costs through planned maintenance

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In commercial facilities, power outages significantly decrease customer satisfaction and lead to substantial losses. The stable operation of electrical equipment is essential for ensuring customer safety and a comfortable usage environment. The deterioration of high-voltage cable insulation is one of the causes of power outages, and regular diagnostics are necessary for early detection and countermeasures. LINDA measures the insulation condition of high-voltage cables while they are live, allowing for the early detection of signs of deterioration and reducing the risk of sudden power outages. This enables commercial facilities to maintain a stable power supply and improve customer satisfaction. 【Usage Scenarios】 - Shopping malls - Office buildings - Hotels - Hospitals - Large commercial facilities 【Benefits of Implementation】 - Reduced risk of power outages - Improved customer satisfaction - Long-term stable operation of electrical equipment - Realization of safe facility management

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the pharmaceutical industry, the accuracy of data and safe information transmission in the manufacturing process are essential for quality control. Particularly in manufacturing facilities that handle hazardous materials, the introduction of wireless networks raises important issues regarding explosion-proof performance and security. An inadequate wireless environment can lead to quality problems due to data loss or unauthorized access. Our explosion-proof access point, the 'EXAP-200S', enables a wireless LAN environment within hazardous material manufacturing facilities and safely supports data collection and analysis in quality control. 【Use Cases】 - Use of tablets, mobiles, and robots within hazardous material manufacturing facilities - Data collection on the production line - Inventory management 【Benefits of Implementation】 - Improved work efficiency through wireless LAN - Strengthened quality control through real-time data collection - Establishment of a safe wireless environment

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our explosion-proof weighing interface 'EXWPS-2'. The EXWPS-2 is an interface device capable of collecting weighing data from explosion-proof scales installed in hazardous material manufacturing areas (Zone 1/Zone 2). 【Features】 ■ Explosion-proof power supply box for explosion-proof scales ■ Directly collects weighing data from RS232C/Wired LAN/Wireless LAN in explosion-proof environments ■ Compatible with Shinko Electronics FZ Series ■ Compatible with Kubota KL-IS Series ■ Connects up to two explosion-proof scales ■ Can incorporate an explosion-proof scanner (EXSC-QB) receiver *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our explosion-proof thin client, the 'EXPC-5170X'. The EXPC-5170X is an explosion-proof thin client that enables PC operation in hazardous material manufacturing areas. Its waterproof design also makes it suitable for pharmaceutical and food cleaning processes. 【Features】 ■Explosion-proof design for use in hazardous locations (Zone 1/Zone 2) ■Waterproof construction suitable for pharmaceutical and food cleaning processes ■17-inch SXGA (1280×1024) display LCD panel ■Resistive multi-touch panel ■IP64 protection rating expands application range Translated with DeepL.com (free version) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our explosion-proof thin client, the 'EXPC-3170X'. The EXPC-3170X is a 17-inch explosion-proof thin client primarily used in hazardous manufacturing environments to access operational systems (server application software) via remote desktop. 【Features】 ■Explosion-proof design for use in Zone 1/Zone 2 ■Can be used as a thin client for ERP/MES systems ■17-inch SXGA (1280×1024) display LCD panel ■Features an ultrasonic touch panel ■UWF function protects the operating system from power interruptions *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Vibro-Collector MD-330" is a compact portable vibration diagnostic device with excellent operability. Thanks to its compact and lightweight design (body 450g + probe 180g), the body weight is about half that of conventional models. The button layout has been designed for one-handed operation. It features a trigger function that is effective for investigating the causes of resonance phenomena occurring on-site. It has become easy to measure natural frequencies and more. 【Features】 ■ Excellent operability with a compact and lightweight design and an easy-to-understand interface ■ IC-TAG reader/writer function streamlines work ■ Easy measurement of natural vibrations ■ Capable of noise processing for inverter motors *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This catalog introduces the high-voltage cable live insulation diagnostic device "LINDA." LINDA is a device for measuring the insulation of 3kV and 6kV high-voltage power distribution lines while energized. It monitors the insulation condition of high-voltage cables, observing trends in insulation degradation to prevent sudden accidents before they occur. ※It is adopted in extra-high voltage power receiving facilities. 【LINDA-1000 Features】 ■ The LINDA-1000 is portable. ■ Customers can choose their own diagnostic timing. ■ We also offer spot diagnostics by our company. ※ A separate measurement terminal board installation is required. 【LINDA-1500 Features】 ■Generates various reports (insulation resistance trend graphs, daily/weekly/monthly reports) ■Economically builds large-scale multi-type systems as one LINDA unit can measure up to 90 circuits ■Measures sheath insulation resistance down to 0.1MΩ (Generally, accurate measurement becomes impossible when sheath insulation resistance falls below 10MΩ) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our explosion-proof touch panels, the 'EXGP-3400R/3600R'. This is an explosion-proof touch panel based on the Schneider Electric Holdings GP4000 series. It is used as an operator terminal for PLCs in hazardous material manufacturing areas. We offer a 12.1-inch model (EXGP-3600R) and a compact 7.5-inch model (EXGP-3400R). ■ Analog resistive touch technology for enhanced operability ■ High-definition LCD panel with 65,536 colors for both 12.1-inch and 7.5-inch models ■ Multi-power supply compatible: AC 100-220V or DC 24V ■ IP64 protection rating ■ Explosion-proof switches/lamps mountable on up to 5 locations on the front panel, plus the explosion-proof buzzer on the bottom panel *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer the Zone 2 dedicated explosion-proof touch computer 'EXPC-6220'. It features a 22-inch Full HD display that can be safely operated even in Zone 2 environments. It runs Windows 10 IoT Enterprise 2021 LTSC and employs a projection capacitive touch system resistant to noise. It also includes various ports such as COM, LAN, and USB. With IP64-equivalent waterproof and dustproof performance, it has been widely adopted by pharmaceutical and semiconductor manufacturers. ■Explosion-proof version of Schneider Electric HD's PS6000 series ■Explosion-proof touch PC terminal with Windows 10 IoT Enterprise PC ■Projected capacitive multi-touch panel ■22-inch Full HD LCD panel ■IP64-rated waterproof protection ■Optional Wi-Fi/Bluetooth communication available *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

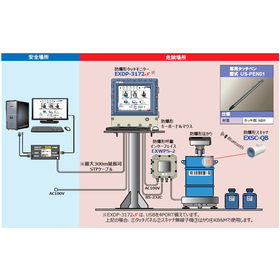

This catalog introduces the explosion-proof touch monitor series EXPC and EXDP. It features the explosion-proof touch computer "EXPC-6220," the explosion-proof touch monitor "EXDP-3172S," the explosion-proof thin clients "EXPC-3170X" and "EXPC-5170X," and the explosion-proof weighing interface "EXWPS-2," among others. The EXPC/EXDP series has a maintenance-friendly pressure-resistant explosion-proof structure. [Contents (partial)] ■ Explosion-proof touch computer "EXPC-6220" ■ Explosion-proof touch monitor "EXDP-3172S" ■ Explosion-proof thin client "EXPC-3170X" ■ Explosion-proof thin client "EXPC-5170X" ■ Options *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This catalog introduces the EXGP series of explosion-proof touch panels. It features the explosion-proof touch panels "EXGP-3600R" and "EXGP-3400R" from the GP4000 SERIES, as well as the explosion-proof scanner "EXSC-QB" that reads barcodes wirelessly. The EXGP series allows for the installation of explosion-proof switches and lamps on the front of the unit, enhancing operability. [Contents] ■ Explosion-proof touch panel "EXGP-3600R" ■ Explosion-proof touch panel "EXGP-3400R" ■ Explosion-proof scanner "EXSC-QB" ■ EXGP series optional explosion-proof switches/lights/buzzers *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our explosion-proof touch monitor 'EXDP-3172S'. IThis explosion-proof monitor is suitable for use in hazardous material manufacturing areas. It enables operation of a computer installed in a safe location via a KVM extender (VGA input). 【Features】 ■Long-term operation possible regardless of Windows OS version due to KVM extension method ■New KVM Extender also extends USB ports ■17-inch LCD monitor ■Ultrasonic touch panel ■Extends VGA up to 300m via STP cable for viewing and operating the remote PC ■KVM extension method ensures system operation continues even during power or communication loss ■Compatible with intrinsically safe explosion-proof keyboards & mouse *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Nearline-PM" is a predictive maintenance system that allows for quantitative and objective management of motors, pumps, fans, compressors, and more through vibration diagnosis using vibration sensors and wireless networks. It visualizes the condition of factory equipment digitally, enabling measurement, data collection, and diagnosis to be performed on a PC. Our company not only provides equipment but also offers suitable implementation proposals based on structural diagrams and equipment information, including the selection of measurement points. 【Features】 ■ Enables preemptive action before failures by predicting equipment abnormalities ■ No wiring work required for vibration sensors ■ Low-cost implementation possible with easy retrofitting and expansion ■ Can start with just one target device *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"vMICKS" is a system designed to prevent human errors such as measurement mistakes and incorrect input during the formulation process, where manual work cannot be eliminated, with the aim of reducing manufacturing losses. It also achieves thorough manufacturing traceability and process management. The system has been successfully implemented even in hazardous material manufacturing locations. Please feel free to contact us when needed. 【Features】 ■ Can also be utilized for traceability ■ Selection of appropriate equipment and instruments according to customer facilities and requirements ■ Proposals not only for system construction but also for equipment maintenance planning and implementation, various maintenance, and system support ■ Verification is performed for each raw material input using explosion-proof operation terminals to prevent input order errors and omissions ■ Realizes reduced wiring and space-saving by utilizing wireless interfaces for explosion-proof weighing instruments *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The 『EXNT-34S』 is a high-performance 6-port managed Ethernet switch and optical media converter that can be used in hazardous locations. Two of the Ethernet ports can be converted to multimode 1000BASE-LX optical fiber, making it suitable for noisy environments within factories, allowing wiring up to 2,000 meters from a safe location. Ports 1 to 4 of the built-in Ethernet switch support PoE, enabling power supply to devices compliant with IEEE 802.3af. 【Features】 ■ Industrial switching hub and optical media converter ■ PoE power supply support ■ Flexible network environment construction in hazardous locations *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "EXAP-200S" is an explosion-proof wireless access point that enables wireless communication within hazardous material manufacturing facilities. In the 5GHz band (IEEE802.11n/a), it can select from channels 19 (W52/W53/W56*1), and in the 2.4GHz band, it can choose from channels 1 to 13 for IEEE802.11n/g and channels 1 to 14 for 11b, allowing for flexible wireless network design considering radio interference. It also supports dual-channel (using a 40MHz width) as per the IEEE802.11n standard. 【Features】 ■ Wireless LAN in explosion-proof areas ■ Supports PoE power supply ■ Switchable between access point (master station), station (slave station), and repeater modes ■ Incorporates proprietary WSL encryption technology compatible with WPA2/WPA and WEP ■ Equipped with diverse functions including VLAN and virtual AP capabilities *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration