1~42 item / All 42 items

Filter by category

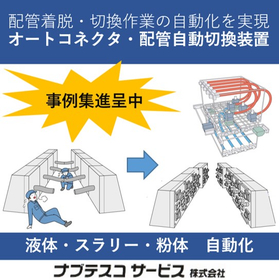

Automatic disconnecting device (auto connector, auto coupler, auto joint)

Nabtesco's automatic connection and disconnection devices (auto connectors, auto couplers, auto joints) can handle not only automatic connections and disconnections for electrical, hydraulic, and pneumatic systems but also for materials and products such as vacuum, steam, thermal media oil, powders, slurries, toothpaste, whiskey, chocolate, hydrochloric acid, wafer cleaning solutions, SUS powders, and high pressure! With over 50 years of experience, we have automated the connection and disconnection of various piping systems across all industries. We design and manufacture everything from individual couplers to entire systems, including operation panels and control panels, tailored to your needs. By incorporating couplers and connectors for automatic connection and disconnection, along with alignment, locking, and dust-proof functions into a multi-unit configuration, we can reliably and quickly connect and disconnect multiple piping and wiring systems, such as auto connectors (auto couplers).