1~26 item / All 26 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~26 item / All 26 items

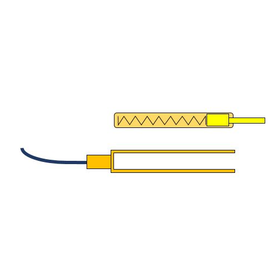

We have developed a contact fixture that uses a leaf spring for high current applications as an alternative to contact probes for terminal contact options. While the freedom of terminal placement is inferior compared to contact probes, it has excellent features such as a permissible current per pin (50A at P=0.4) and high load capacity. Previously, contacts were made by directly inserting contact probes, mold sockets, and leads into connectors, but we are now proposing a new option. 【Lineup】 ■ HC-C (High Current Cube) ■ IC Socket Type *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have successfully developed probes with low magnetic properties by processing parts made from materials we have uniquely selected to meet more advanced requirements. Additionally, thanks to our accumulated know-how, we can provide comprehensive proposals that include housing design and manufacturing. Please feel free to contact us when you need our services. 【Features】 ■ Components of probes other than springs are processed and manufactured in-house. ■ We can manufacture various custom probe tip shapes tailored to the contact target. ■ We are also open to consultations for items not included in the standard lineup. ■ In addition to non-magnetic properties, we can accommodate contact testing under various conditions, including high current loads, high-temperature loads, and high-frequency characteristics. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the usage of the "Contact Probe" that we handle. The "Standard Contact Probe (Single-End Probe)" is basically used in pairs with a socket due to the ease of replacement and wiring. The general method of using a contact probe involves drilling a hole in the resin, embedding a socket (receptacle) in it, and connecting the lead wires for wiring. Finally, the contact probe is inserted into the socket to complete the setup. Additionally, our website also provides information on "How to Use a Double-End Contact Probe" and "Replacing a Double-End Probe." [Content Included] ■ How to Use the Standard Probe ■ How to Use the Double-End Probe ■ Replacing the Double-End Probe *For more details, please refer to the PDF materials or visit our website.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company designs and manufactures "contact probes, IC sockets, and probe cards" used for semiconductor testing. ▼ Contact Probes We offer not only standard products but also flexible solutions tailored to testing conditions. ▼ Probe Cards and IC Sockets We can provide consistent processing and assembly of resin, allowing us to offer testing fixtures suited to the inspection targets at low costs. 【Examples of Support】 ◎ Narrow pitch support (manufactured with MIN P=80μ) ◎ High current testing (manufactured for pre-process testing of IGBT devices) ◎ Non-magnetic testing (probes made from non-magnetic materials) ◎ Others: High frequency (10GHz), high heat resistance (below 300℃), etc. 【Product Examples】 ▼ Contact Probes - Reduces the hassle of replacement. Durable "rare metal probes." - Revised internal structure. "New bias probes" for stable resistance value measurement. ▼ IC Sockets - Non-magnetic sockets, high heat resistance sockets. ▼ Probe Cards - Probe cards compatible with min 80μ pitch. - High current load test probe cards. *For more details, please refer to the materials. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are engaged in circuit board design at our group company, Shinano Seiken. With 30 years of experience in circuit board design, we provide design techniques that ensure patterns free from malfunctions. While circuit board design is becoming increasingly automated, especially in analog boards, it requires the experience and skills to anticipate potential issues and reflect them in the design. We conduct circuit board design that avoids risks based on our extensive experience and accumulated know-how. Additionally, we strive for user-friendly component placement that considers the workability of users handling the circuit boards. ☆ Circuit Board Design - Medical device-related boards - Power protection-related boards - Transmission and reception high-frequency boards We own CAD software including ZUKEN Design Force. We also have environments where older CAD software can be used, allowing for data restoration in some cases. There are many instances where we are consulted for cause investigation when issues arise with circuit boards designed by other companies. We can also handle everything from circuit board design to manufacturing, component mounting, assembly, and wiring consistently at Shinano Seiken. *For more details, please download the PDF or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide assembly and wiring work services at our group company, Shinano Seiken. ☆Assembly☆ We handle assembly work for both large and small items, from small lots (1 unit) to larger quantities. We have experience in harness production and precision equipment assembly. ☆Typical Work Content☆ Torque management for screw tightening Use of two-component adhesives Precision work using tweezers Precision work using microscopes Cable processing and wiring assembly work based on circuit diagrams Material cutting with a grinder Mechanical assembly Drilling work with a drill press (machining) Deburring of various components *Please feel free to consult us about other tasks as well. ☆Remote Meeting Support☆ We accommodate remote meetings using the video chat tool ZOOM. For tasks that require a focus on sensory aspects, there may be parts that are difficult to explain only through descriptions, but there are many assembly tasks that can be addressed through video chat explanations. We have a flexible system in place for meetings. *For more details, please download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide precision tweezers at our group company, Shinano Seiken. Precision tweezers. Have you been using the ones you purchased new without any modifications? Tweezers can improve work efficiency by processing the tips according to the task at hand. ☆ Tweezers that grip firmly By being able to securely grasp the object from any angle, work efficiency is enhanced. If the tweezers are too thin or if the tips are misaligned, the effective gripping range becomes narrower. In this situation, a technique is required for the task, making it difficult for some users and resulting in an inefficient working environment. Using tools in good condition allows everyone to proceed with their work smoothly. * We do not modify the tweezers you already own; we sell tweezers that have been processed according to our specifications. * Please understand that due to being handmade, each piece may have a different shape. * For more details, please download the PDF or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company designs and manufactures "contact probes, IC sockets, and probe cards" used for semiconductor testing. ☆Contact Probes☆ We can flexibly accommodate not only standard products but also special specifications tailored to testing conditions. ☆Probe Cards and IC Sockets☆ We can provide consistent processing and assembly of resin, allowing us to offer testing fixtures suitable for the inspection target at a low cost. 【Examples of Support】 ◎ Narrow pitch support (manufactured with MIN P=80μ) ◎ High current testing (manufactured for pre-process testing of IGBT devices) ◎ Non-magnetic testing (probes made from non-magnetic materials) ◎ Others: high frequency (10GHz), high heat resistance (below 300℃), etc. 【Product Examples】 <Contact Probes> - Reduces replacement hassle. "Rare metal probes" with excellent durability. - Revised internal structure. "New bias probes" for stable resistance value measurement. <IC Sockets> - Non-magnetic compatible sockets. - High heat resistant sockets. <Probe Cards> - Probe cards compatible with min 80μ pitch. - High current load test probe cards. *For more details, please refer to the materials. Feel free to contact us with any inquiries.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer a one-sided movable probe as a standard probe in our catalog. However, when trying to match it to equipment used for electrical testing, it may not meet the specifications. We can suggest existing probes tailored to the products or equipment conditions you wish to test, but if there is no suitable probe available, we can manufacture a custom one. In addition to partially manufacturing new parts based on existing probes, we can also create all parts from scratch. Therefore, if you need a replacement or compatible probe due to the discontinuation of a probe manufactured by another company, we may be able to assist you. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The spring material for general contact probes is piano wire. Essentially, it is designed for use at room temperature, but piano wire can also be used in environments around 100 degrees without significant loss of load. However, when the temperature exceeds 150 degrees, the load may decrease due to heat, which can result in an inability to achieve the specified contact pressure. In such cases, using springs made of SUS material can improve the situation, but when temperatures exceed 200 degrees, even this material can experience a decrease in load. At Seiken, we also offer probes that use springs rated for 300 degrees heat resistance, which is a step up from SUS material. Not only does the measurement environment involve high temperatures, but the high heat-resistant springs also contribute to stable measurements against the heat generated by passing large currents through the probes themselves. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Seiken, in addition to our approach to surface treatment, we have re-evaluated the materials themselves. Traditionally, we used BeCu (beryllium copper), which required surface treatment. However, we have processed an alloy that excels in solder contact properties, allowing it to be used as is without any surface treatment. Even when cleaning the pin tips, the plating thickness is at most 1-2 micrometers, but since the alloy is used in its solid form, there is no risk of plating peeling that would expose the base material and degrade performance. Additionally, the hardness is comparable to or greater than that of traditional BeCu, so wear resistance is not a concern. This material can also be processed for probes in the P=80 micrometer class. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By using a bias structure and inserting a ball, we were able to increase the contact pressure on the inner wall of the pipe; however, this also resulted in significant damage to the inner wall, leading to issues such as probe sticking when used repeatedly. To address these disadvantages, Seiken combined parts using precision machining technology instead of balls, thereby reducing damage to the inner wall of the pipe while maintaining the characteristics obtained through bias. Furthermore, by miniaturizing the parts, we can also create a bias structure compatible with P=0.4mm. We respond to the need to minimize variations in resistance values specific to contact probes, such as in low-resistance measurements. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Seiken, we offer a lineup of vertical probes compatible with P=150um. The tip is made of a well-regarded alloy known for its contact with solder and is also compatible with crown cuts, allowing for stable contact with bumps. By using a specially shaped spring to maintain a constant load, the contact with bumps is better than that of probes using standard springs with the same pitch. 【Features】 ■ Lineup of vertical probes compatible with P=150um ■ Alloy compatible with crown cuts ■ Stable contact with bumps ■ Maintains a constant load using a specially shaped spring ■ Good contact with bumps *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kelvin Probe" has its tip positioned right at the edge of the probe's outer shape. By moving the tip outward, it is possible to minimize the gap between two points without changing the thickness of the pin. This allows for stable contact at a fixed position and the maintenance of load. Special board processing is required for use. Our company offers the fabrication of fixtures that can be installed according to the measuring equipment used by our customers. 【Features】 ■ The tip is positioned right at the edge of the probe's outer shape. ■ It can minimize the gap between two points without changing the thickness of the pin. ■ Stable contact at a fixed position. ■ It can maintain load. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The needle-shaped probe itself is processed from a metal with good machinability, and we have succeeded in bonding rare metals such as iridium and rhodium to its tip. This technology has enabled us to incorporate rare metals, which could only be shaped into simple forms through polishing, into components of probes that require complex machining. The hardness of BeCu (beryllium copper), which is the material commonly used for probes, is about HV400, while iridium and rhodium have hardness exceeding HV1000. In addition to their hardness, these materials also exhibit excellent electrical properties. Therefore, they can maintain stable contact with electrodes of various materials for an extended period, allowing for an extended maintenance cycle. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To non-magnetize contact probes, it is essential to review the materials and surfaces, but in practice, that alone is not sufficient for the product to be viable. It is only natural that they should be non-magnetic when measuring non-magnetic devices, but they must also possess performance tailored to the characteristics of the electrodes being inspected. Our company offers a lineup of "non-magnetic probes" that are suitable for lead-free electrodes, provide load control for contact probes, and achieve a pitch of P=0.2mm. [Features] ■ Materials suitable for lead-free electrodes ■ Load control for contact probes ■ Achieves pitch compatibility of P=0.2mm *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Recently, the conditions for inspection targets have become stricter, such as lead-free solder, contact with aluminum electrodes, and high current measurements, leading to cases where traditional processing is insufficient in performance. CNTs are strong against current and heat and have features that improve contact with aluminum. By incorporating them into the gold plating of probes, we have successfully enhanced the electrical performance of the gold plating. As a result, even when the contact probe is in contact with aluminum electrodes, it can maintain stable contact for a longer period. Additionally, in high current measurements where traditional pins would physically break due to current overload, we have significantly improved the performance of the probes. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to our "Contact Probe (Dual Pin)" that we handle. We offer two types: one with movable plungers on both sides and one with a movable plunger on only one side. The sizes range from long and thick ones with an overall length of 20mm and a thickness of approximately φ1.0mm, to shorter and thinner ones with an overall length of L=1.5mm and a thickness of φ0.1mm. The tip shape can be selected similarly to standard contact probes. 【Features】 ■ Two types are available: one with movable plungers on both sides and one with a movable plunger on only one side ■ The tip shape can be selected similarly to standard contact probes ■ The plunger on one side makes contact with the electrode of the relay board ■ Wiring is also possible using enamel wire attached to metal terminals ■ When in use, 2 to 3 boards are utilized *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The world is filled with a wide variety of electronic components. They vary greatly, from standardized ones to unique shapes tailored to individual users. Moreover, if the shape of the electronic component differs, the position and size of the electrodes where the probes make contact during inspection will also differ. Additionally, the measurement methods used by users can vary, ranging from manual processes to automated systems with handlers. Taking all these conditions into account, we meticulously examine the shape of the probes and the materials of the blocks to create pin blocks that match the user's inspection environment. To put it bluntly, Seiken is a company that does anything that involves making contact using probes. Connectors are indispensable in the composition of electronic devices.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to Seiken Co., Ltd., which handles contact probes used for electrical testing, semiconductor wafer inspection probe cards, and IC sockets. We offer a lineup of products including "contact probes" that cater to both standard and special specifications, "IC sockets" that can be configured with housing materials suited to specific applications, and "probe cards" that accommodate various inspection conditions, including narrow pitch through fine processing technology. Examples of inspection conditions: - Support for narrow pitch (MIN P=80μ) - High current testing (pre-process testing of IGBT devices) - Non-magnetic testing (probes made from non-magnetic materials) Leveraging the technology we have cultivated over many years, we continue to develop solutions that provide a more efficient inspection environment and meet more detailed requests. An overview of our products is available in the documentation. [Contents] ■ Introduction ■ Product and technology introduction (Contact Probes) - Introduction of new product technology ■ Technology introduction (IC sockets, probe cards) ■ Other various products and services (precision processing, etc.) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company is a manufacturer that has developed and designed inspection equipment essential for quality assurance. Since our establishment in 1984, we have started manufacturing and selling probe pins and various inspection jigs as a specialized manufacturer. Since then, we have responded to customer demands in various markets, including semiconductor component inspection jigs such as probe cards and IC sockets, as well as LCD panel inspection jigs. As a leading company in the industry, we have refined and honed our precision processing and assembly technology over many years. Keeping pace with the changes of the times, we will continue to be a good partner for our customers as a "TOTAL TEST SOLUTION" provider, tackling challenges in inspection operations with various products and services. In recent years, we have also been providing the technologies and know-how we have accumulated in producing our products through our EMS business. In addition to our unique skills, we also provide various support in manufacturing through matching customers with our partner companies and related firms. Seiken will always challenge itself, create new value, and pave the way for the future of Japanese manufacturing.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Probes for semiconductor testing can be selected according to the measurement environment. - Probes made from our unique alloy material that enhance contact performance for lead-free applications. - Heat-resistant probes that utilize special springs to avoid load reduction due to thermal effects. - High-level non-magnetic material probes that can also be used for testing magnetic sensor components. - Short high-frequency probes that maximize signal transmission characteristics. We respond to various user requests. 【Features】 ■ Excellent quality backed by years of experience ■ A wide range of products ■ Various selections available for probe tip material, surface treatment, tip shape, etc., tailored to the measurement target device ■ Custom specifications are also available, allowing for arbitrary settings of total length, tip diameter, and spring pressure beyond standard specifications. *For details, please request materials or view the PDF data available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Product Catalog】【Usage Instruction Materials】 Contact probes (also known as pogo pins or test probes) have been used for continuity testing of electronic components. Our company has over 30 years of experience as a specialized manufacturer of probe pins. The structure consists of a spring inside a tube, and the tip (the plunger) makes contact with the electrode being tested with the appropriate load by stroking. The product catalog offers a lineup of 15 types for each pitch (the spacing between probes). Each series has multiple tip shapes available. Our probe pins are manufactured in-house, from processing the parts to assembly. Therefore, we can produce custom specifications to meet various requirements. 【We also accept resin board processing】 In addition to providing probes, we also offer processing of the resin that secures the probes. Furthermore, we can provide the probes with sockets integrated into the board and wiring to connectors. We also accept requests for resin processing only, so please feel free to contact us. *For more details, please download the PDF or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

TFT LCD and OLED displays are incorporated into various electronic devices such as televisions and mobile devices, and advancements in high definition and miniaturization are progressing. The functions and required quality assurance are diversifying rapidly, and there are increasingly sophisticated demands for inspection applications in the cell testing process and module process. These display inspections are essential for maintaining quality. Our company provides original inspection fixtures, signal generators, and LED backlights, all designed in-house. We contribute to the quality improvement of panel manufacturers. *For more details, please download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company is a manufacturer of contact probes used for inspecting various electronic components, as well as inspection fixtures that utilize these probes. The technology required in these fields is at an extremely high level, characterized by "ultra-high precision" and "ultra-fine" specifications. Our technology, which has been refined over many years to meet these demands, has solved various challenges not only in inspection-related areas but also across a wide range of applications. We also offer this technology as a processing contract service. *For more details, please download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In recent years, electronic devices are required to be high-performance, durable, and adaptable to various environments. To meet these demands, connectors also need to diversify. However, commercially available connectors often fail to meet the required specifications, leading to many cases where specifications are reluctantly changed. Therefore, our company applies the technology cultivated in the inspection field to the custom connector sector, creating attractive products and contributing to solving the problems faced by many users. *For more details, please download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration