No dedicated technician is required, and anyone can use it. It scans the interior of products at a micrometer level. It is widely used in product development, quality control, and more!

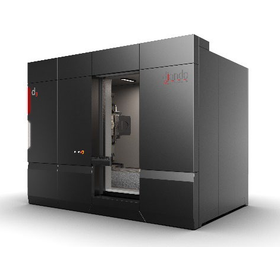

The inxpeXio SMX-225CT is a domestically produced micro-focus X-ray CT scanning system. With its intuitive user interface, anyone can easily observe the internal structure of the target workpiece. It accommodates a wide range of applications, from miniaturized electronic devices to aluminum die-cast products in automobiles, all with a single unit. [Main Features] ● Equipped with an automatic positioning function for CT scans using an appearance camera (industry first) There is no need to position while viewing fluoroscopic images as in the past; the scan position and area can be determined semi-automatically. This significantly reduces the time required before starting the scan. ● No calibration required The cumbersome calibration work that was previously necessary before CT scanning is no longer needed. You can start the CT scan simply by setting the sample and clicking the start button. ● Automatic X-ray condition setting function according to the sample (industry first) For the first time in industrial X-ray CT, we have equipped the device with an "automatic X-ray condition setting function" that automatically adjusts the X-ray transmission settings. For more details, please request a catalog or view the PDF data by clicking the download button below.

Inquire About This Product

basic information

[Machine Specifications] Model Name: inxpeXio SMX-225CT FPD Maximum Work Size: φ350×H300mm Maximum Work Weight: Up to 9kg X-ray Generation Device: Open type Rated: 135W, Maximum Tube Voltage: 225kV, Maximum Tube Current: 1000μA X-ray Generation Device: Flat Panel Detector High-Speed Calculation: Yes Model Name: inxpeXio SMX-225CT Maximum Work Size: φ300×H300mm Maximum Work Weight: Up to 9kg X-ray Generation Device: Open type Rated: 135W, Maximum Tube Voltage: 225kV, Maximum Tube Current: 1000μA X-ray Generation Device: Image Intensifier High-Speed Calculation: No Model Name: HPC inxpeXio SMX-225CT Maximum Work Size: φ300×H300mm Maximum Work Weight: Up to 9kg X-ray Generation Device: Open type Rated: 135W, Maximum Tube Voltage: 225kV, Maximum Tube Current: 1000μA X-ray Generation Device: Image Intensifier High-Speed Calculation: Yes

Price range

Delivery Time

Applications/Examples of results

Non-destructive testing (casting defects/defect analysis, damage inspection, assembly inspection, etc.), evaluation/dimensional measurement of product interiors is utilized in various scenes of manufacturing, such as reverse engineering.

Detailed information

-

No dedicated personnel required! A CT scanner that anyone can operate. When setting the CT scan area, you can intuitively position the center and set the scan area using the mouse while looking at the screen. No specialized CT technicians are needed, and no special facilities or dedicated rooms are required.

-

Achieving high-speed CT scans through the parallelization of imaging and computation. Traditionally, calculations were performed after imaging was completed, resulting in delays in data display. "HPC inspeXio" can perform calculations in parallel while scanning, completing computations 80 to 170 times faster than conventional methods and significantly reducing the time to data display.

-

Design considering safety [Interpersonal] While the sliding door is open, all mechanical operations, including X-ray exposure, are completely stopped. The door is designed so that it cannot be operated with one hand to prevent finger pinching accidents.

-

Design Considerations for Safety [Against Workpiece] Equipped with functions to prevent workpiece collisions. Sensors detect collisions from all directions: front, below, and sides. The stage movement speed changes according to the magnification, allowing for collision avoidance.

-

Reference Observation This is a photo observed with reference to the AA series pin gauge Φ4.0mm manufactured by Niigata Seiki Co., Ltd.

catalog(19)

Download All CatalogsCompany information

【Proposing the latest and standard equipment for manufacturing through a system】 We are the only company in Japan that can provide a comprehensive proposal for all the equipment necessary for manufacturing, including machine tools, CAD/CAM, 3D printers, 3D scanners, and other 3D digital production tools and instruments. 【Peace of mind with technical support after installation】 With our strength in technical support, we can resolve any concerns of users after installation, such as operation assistance, troubleshooting, and maintenance, all through a single point of contact. 【Extensive display of actual machines】 We have various actual machines set up, allowing you to clarify your operational image through demonstrations and tours before making a decision to implement. 【Manufacturer capabilities】 Additionally, if there are no products with the features desired by users, or if there are products with good features but weak sales power, we will leverage our manufacturer capabilities to release them as uniquely planned in-house products.

![CT scan application example [Quality control of electronic circuit boards]](https://image.mono.ipros.com/public/catalog/image_generated/01/1c4/319935/319935_IPROS7110287696818229364_1.jpg?w=120&h=170)

![CT scan application examples [Reverse Engineering / LAN cable connectors, spray nozzles]](https://image.mono.ipros.com/public/catalog/image/01/d77/321067/IPROS4050236696053885143.jpg?w=120&h=170)

![Case Studies on the Use of Industrial CT Scan Data [Internal Inspection/Observation/Design]](https://image.mono.ipros.com/public/catalog/image/01/966/325911/IPROS7823872852782056745.png?w=120&h=170)

![3D Digital Technology Contract Services [CT Scan, 3D Scan, 3D Print]](https://image.mono.ipros.com/public/catalog/image/01/8e2/243382/IPROS58047584421062449620.jpeg?w=120&h=170)

![Case Studies on the Utilization of Medical CT Scan Data [Utilization of DICOM Data]](https://image.mono.ipros.com/public/catalog/image_generated/01/2ab/371684/371684_IPROS1819148461467970195_1.jpg?w=120&h=170)

![[New Product] High-Power X-ray CT System 'YXLON UX50'](https://image.mono.ipros.com/public/product/image/889/2000689601/IPROS5269998389996976078.jpg?w=280&h=280)

![[UHS_X-ray CT System Imaging Example] Smartphone Internal Circuit Board](https://image.mono.ipros.com/public/product/image/02e/2000999324/IPROS78601748669565101722.jpeg?w=280&h=280)