Are you having trouble with the "electrostatic destruction" of the Cr glass mask?

[Technical materials are available for free!] The conductive layer suppresses electrostatic breakdown! Achieving stable quality, cost, and delivery times with a high yield rate.

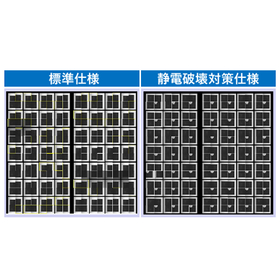

Our "Cr Glass Mask for Electrostatic Discharge Protection" is a photomask that is less likely to suffer pattern damage even when charged objects approach. It can handle a large number of exposures without damage using just one piece. This not only reduces the costs associated with mask replacements but also contributes to improved production efficiency by maintaining a stable production speed. Additionally, leveraging our extensive experience in mass production of electrostatic discharge protection products, we offer photomasks with high charge dissipation performance within the same lead time as standard products! **Features of the Cr Glass Mask for Electrostatic Discharge Protection:** - Resistant to damage even when approached by charged personnel or equipment - High dirt and cleaning resistance - Excellent fine feature resolution, enabling high-precision pattern formation - Suitable for photomasks for electronic components and calibration plates *For more details, please refer to the PDF document or feel free to contact us.*

Inquire About This Product

basic information

【Specifications】 ◎ Maximum mask size: 800×800×12t ◎ Coating thickness: 0.125μm ◎ Accuracy rank ・Mode-A': Narrowest 0.75L/Sμm / Short dimension accuracy ±0.075μm / Long dimension accuracy ±0.5μm ・Mode-A: Narrowest 1.0L/Sμm / Short dimension accuracy ±0.1μm / Long dimension accuracy ±1.0μm ・Mode-B: Narrowest 2.0L/Sμm / Short dimension accuracy ±0.2μm / Long dimension accuracy ±2.0μm ・Mode-C: Narrowest 3.0L/Sμm / Short dimension accuracy ±0.5μm / Long dimension accuracy ±1.5μm ・Mode-D: Narrowest 5.0L/Sμm / Short dimension accuracy ±0.5μm / Long dimension accuracy ±2.0μm ・Mode-E: Narrowest 8.0L/Sμm / Short dimension accuracy ±1.5μm / Long dimension accuracy ±4.0μm 【Applications】 ◎ Pattern originals for PWB, FPC, electronic components, etc. ◎ Calibration plates (for measurement and equipment adjustment) *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the materials. Feel free to contact us as well.

catalog(1)

Download All CatalogsCompany information

Takeda Tokyo Process Service has started anew as Takeda iP Holdings, following the integration of the Takeda Printing Fine Process Division and Tokyo Process Service in April 2023. The brand "TOPRO," known for its top-tier technology in Japan, will further develop as "Takeda To-Pro" by incorporating advanced techniques cultivated in printing and plate-making. We support our customers' product development with attentive and prompt service. We respond to customer requests and inquiries quickly and carefully, ensuring a robust system at all times. We are flexible in accommodating requests for trial production, starting from just one piece, as well as small lot orders. Please feel free to contact us first. *Quality Management System ISO 9001 certified, Environmental Management System ISO 14001 certified.

![[Technical Information] No more worries about static electricity! Recommended ESD countermeasures (static electricity discharge measures) by Takeda Higashi: 4 selections!](https://image.mono.ipros.com/public/catalog/image/01/ade/483743/IPROS251875001280869864.jpeg?w=120&h=170)

![[Problem-Solving Material] Surface Processing to Solve Issues with Photomasks](https://image.mono.ipros.com/public/product/image/652/2000735802/IPROS23296740697191074.png?w=280&h=280)