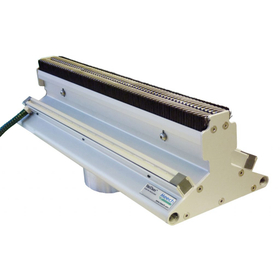

Hybrid welding machine TH3-2040 capable of performing three functions with one unit.

Hybrid Welding Machine TH3

A 3-axis servo-driven welding system capable of handling three types of welding: heat plate welding, infrared welding, and hot gas welding (patented technology) with a single welding machine.

Dukein's hybrid welding machine: The TH3 series can switch between hot plate welding, infrared welding, and hot gas welding using a single device. You can choose the appropriate method for the product being welded; for example, "Product A is made of natural PP, so it is produced using hot plate welding, Product B is made of PA+GF30, so it is produced using infrared welding, and Product C contains electronic components, so it is produced using hot gas." Hot gas welding is a patented technology from Dukein KVT (Germany) that sprays high-temperature inert gas only onto the welding area, melting it without contact, which prevents oxidation of the welding area and achieves high welding strength. Infrared welding also uses short-wavelength infrared quartz heaters for non-contact heating, enabling clean welding without particle generation. Hot plate welding is the most widely used welding method and can achieve the fastest cycle times when using natural materials.

Inquire About This Product

basic information

- Capable of handling three welding methods: heat plate welding, infrared welding, and hot gas welding with a single machine. - High reproducibility achieved through 3-axis servo control. - High-speed servo motion minimizes the time from heating completion to joining, reducing cycle time and minimizing temperature drop at the welding area, resulting in high welding strength. - Supports heater control for up to 12 zones (6 upper + 6 lower) for both heat plate and infrared, allowing optimal temperature settings (output settings for infrared) for each part of the product. - The 15-inch touch panel is easy to read and allows for intuitive operation and programming (supports Japanese display). - Quick fixture exchange function enables fast changeover in a short time. - The "DUKANE" logo at the top front of the device indicates the device's status through color.

Price range

Delivery Time

Applications/Examples of results

Various automotive parts, home appliances, medical components, etc.

Line up(3)

| Model number | overview |

|---|---|

| TH3-2040 | Heater platen size: 1016 x 508 mm |

| TH3-1432 | Heater platen size: 813 x 356 mm |

| TH3-1212 | Heater platen size: 305 x 305 mm |

catalog(2)

Download All CatalogsCompany information

Dukane Japan is the Japanese subsidiary of Dukane IAS LLC, headquartered in St. Charles, Illinois, USA. It supports various plastic welding processes with its unique advanced technologies, including ultrasonic servo welders utilizing servo control technology, ultrasonic probe systems that can be controlled and monitored from external PLCs via Ethernet IP connection or CC-Link connection, vibration welders capable of high-precision welding with high mechanical rigidity, and the Servo Weld Plus (Dual Servo) spin welder that performs rotation and pressure control via servo. Additionally, with the motto "One World, One Dukane," it offers comprehensive support in countries and regions outside Japan through a worldwide network that spans major industrial nations. This allows for the relocation of equipment purchased in Japan to overseas locations for local service, as well as the maintenance of equipment relocated from abroad in Japan.