Significantly improve the setup efficiency of wire cutting and wire EDM machines with simple screwdriver tasks! This is a leveling base for parallel alignment.

For wire cutting processing, it is necessary to adjust by inserting shims to ensure the workpiece is parallel. The parallelism of the workpiece has a significant impact on the final product finish, so the processor spends a lot of time on this setup. It is a time-consuming and tedious task. However, since the machine is not operating during setup, from a management perspective, it is preferable to minimize the time spent on this... The solution to this is our designed and developed leveling base, the "PAD series"! It can easily resolve the leveling required for the pre-setup of wire cutting, which has previously taken a lot of time, with just this one product! By adopting precision balls at the support points, the independence of each adjustment axis is high, making it easy to adjust without affecting the results of other axes. Additionally, it has high durability due to simplified structure and a design that prevents foreign objects from entering the spring components. 【Features】 ■ Easily resolves leveling tasks ■ Significantly improves setup efficiency ■ High durability *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

Related Videos

basic information

【Product Information Details】 ●Product Name: Leveling Base for Wire Cutting "PAD200"・"PAD300" ●Release Date: December 23, 2021 (Thursday) ●External Dimensions: 110×105×28 ●Included Accessories: Bolts and Washers (2 each) 【How to Use】 Attach a sub-plate or vice to the product (leveling base) and secure the workpiece. ↓ Prepare a hex wrench and adjust the hex bolts of the leveling base to match the tilt of the workpiece. ↓ Done! No more spending 20 or 30 minutes inserting shims and checking with a dial... Insert shims and check with a dial again... The tedious long adjustment process can be resolved in just 5 minutes by simply turning a screw! 【Lineup】 □PAD200: Leveling base with 2-axis adjustment function → Allows adjustment of 1mm/100mm in two horizontal directions □PAD300: Leveling base with 3-axis adjustment function → Allows adjustment of 1mm/100mm in two horizontal directions and 1.3mm/100mm in parallel.

Price range

Delivery Time

Applications/Examples of results

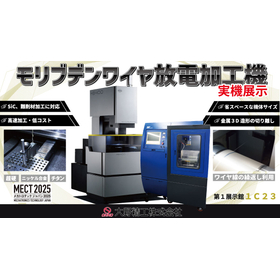

【Usage】 ■ During setup of wire cutting (wire electrical discharge machining) ■ During setup of molybdenum wire electrical discharge machining *For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsNews about this product(5)

Company information

At Ohno Seiko Co., Ltd., we primarily offer sales of electrical discharge machines, mirror finish processing, and precision parts processing. 【Sales of Molybdenum Wire Electrical Discharge Machines】 We have a business partnership with Suzhou Sanguang Technology Co., Ltd. We are the exclusive domestic distributor for the "HB Series" of molybdenum wire electrical discharge machines. Please feel free to contact us for test processing and other inquiries. 【Sales of Original Jigs】 We sell the "PAD Series" of parallel jigs for wire cutting, utilizing patented technology. 【Others】 - Sales of pneumatic positioning jigs, among others. 【Precision Parts Processing】 In a temperature-controlled room maintained at 20℃±1℃, we possess the latest three-dimensional measuring machines (three units), shape measuring instruments, tool microscopes, surface roughness measuring instruments, and more. We continue to challenge the limits of ultra-mirror finish processing with an Rz of 0.2μm and ultra-precision processing. Please feel free to contact us for prototypes and other requests.

![[Patent Granted] Parallel Setup Jig for Wire Cutting | PAD Series | Ohno Seiko Co., Ltd.](https://image.mono.ipros.com/public/catalog/image/01/1cf/621376/IPROS94588078684999030733.jpeg?w=120&h=170)

![[Product Catalog] CNC Molybdenum Wire EDM Machine | HB Series | Ohno Seiko Co., Ltd.](https://image.mono.ipros.com/public/catalog/image/01/823/580826/IPROS09815343317524146078.png?w=120&h=170)

![[Case Study] Cutting Example of Inner Diameter Processing Using Wire Cut Electric Discharge Machine](https://image.mono.ipros.com/public/product/image/2000368/IPROS14653096754280444331.jpg?w=280&h=280)

![[Case Study] Solving the production of complex-shaped parts with wire electrical discharge machining.](https://image.mono.ipros.com/public/product/image/16d/2000742809/IPROS85364594581139627370.png?w=280&h=280)