Pro Manual! Top 5 Approaches for Software Countermeasures in Factory Poka-Yoke Examples

Top 5 effective poka-yoke (soft) tools to prevent human errors and operational mistakes in manufacturing, applicable to small-lot production processes with a variety of products.

To prevent human errors and work mistakes in the manufacturing industry, it is essential to use poka-yoke tools in advance to eliminate the potential for errors. Here are the top five software tools for this purpose: Best 1: Work Observation and Improvement Flowchart Best 2: Human Error Prevention Measure Evaluation Sheet Best 3: In-Process Completion Flowchart Best 4: Work Breakdown Sheet Best 5: Defect Analysis Map Sheet Additionally, we introduce examples of poka-yoke tools. Flowcharts and format sheets are available for free download.

Inquire About This Product

basic information

Powerful Support Menu to Pave the Future of Small and Medium Manufacturing ■ Online Young Leader Factory Management Skills Improvement Seminar (4-part series) http://factorysupport-takasaki.com/article/493421683.html ■ Ready-to-use Pro Manual (for self-study, training young employees, on-site improvement guide) http://factorysupport-takasaki.com/article/424984376.html ■ Affordable Subsidy Application Support Support for Business Restructuring Subsidies / Monozukuri Subsidies / Overseas Supply Chain Diversification, etc. http://factorysupport-takasaki.com/article/498424788.html ■ Monozukuri Support Plastic Prototype Mold Design and Production (Automotive, Medical), High Gloss Coating (Piano Black) http://shanghai-swifttech.com/ ■ Free Online Consultation https://mailform.mface.jp/frms/bintian/8s3ieuzwsa8f

Price range

Delivery Time

Applications/Examples of results

【Purpose】 This will be used as a tool for implementing preventive quality measures and quality improvement measures suitable for frontline manufacturing technology, quality technology staff, and managers of manufacturers of automotive parts, industrial machinery parts, and unit manufacturers. 【Skills and Knowledge to be Acquired】 1. Reliability design methods for manufacturing processes 2. Creation of QC process charts/work instructions and work verification methods 3. Error-proofing methods 4. Ergonomic analysis methods for human errors 5. Work observation and improvement methods using IE techniques 6. Environmental/work action improvement methods that cause human errors 7. QA network methods 8. Correct why-why analysis methods usable on-site 9. Skills and capability training methods that on-site managers should possess 10. Work breakdown and training methods using TWI-JI 11. Systematization methods for managing 4M change points 12. Special process management methods 13. 100% inspection and sensory inspection methods 14. Defect analysis map methods for preventing recurrence 15. Construction of a quality information knowledge system Others

Detailed information

-

The concept of countermeasures for human error (poka-yoke).

-

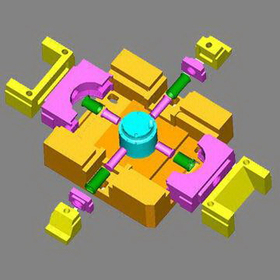

I expressed the types of poka-yoke using a cause-and-effect diagram.

-

Effective work observation and improvement methods as a poka-yoke for soft (system) mechanisms.

-

This is a workflow for work improvement.

-

This is a human error prevention measure evaluation sheet.

catalog(8)

Download All Catalogs![Poka-Yoke (Soft_Hard) Case Studies Best 5 [Pro Manual for Immediate Use on Site] <Free: Format Forms & Mini Explanations>](https://image.mono.ipros.com/public/catalog/image/01/46c/657692/IPROS42733908146846401220.jpeg?w=120&h=170)

![Human Error Prevention Procedure Manual for Manufacturing Sites [Pro Manual for Immediate Use on Site] <Free: Format Template & Mini Explanation>](https://image.mono.ipros.com/public/catalog/image/01/12c/636039/IPROS71398125840504913444.jpeg?w=120&h=170)

![Basic Quality Control for Young Employees [Pro Manual for Immediate Use on the Job] <Free: Format Forms and Mini Explanations>](https://image.mono.ipros.com/public/catalog/image/01/303/619959/IPROS12054415947171174855.jpeg?w=120&h=170)

![Human Error Thorough Countermeasure Course (Basic Edition) [On-Demand Distribution Site Leader Training Text] <Free: Format Form & Mini Explanation>](https://image.mono.ipros.com/public/catalog/image/01/61d/631359/IPROS48156142459654645496.jpeg?w=120&h=170)

![On-site Leader Quality Improvement Procedure Manual, Text, and Manual Series [Pro Manual for Immediate Use on Site] Self-Development and In-House Training Textbook](https://image.mono.ipros.com/public/catalog/image/01/8e9/653132/IPROS31923102756973421912.jpeg?w=120&h=170)

Company information

■Company Name: Takasaki Swift Technology Solutions Co., Ltd. ■Established: March 1, 2014 ■Company Incorporation: August 15, 2017 ■Representative: Representative Employee Kanou Hamada ■Capital: 2 million yen ■Sales: 20 million yen ■Main Business: Manufacturing Technology Consulting (Quality Improvement/Productivity Enhancement) ● Subsidy Application Support (Restructuring Subsidy, Overseas Supply Chain Resilience Subsidy, etc.) ● Contract Design and Manufacturing of Molds, etc. (Prototype Molds, Parts Machining, Glossy Coating, etc.) ● Manuals and DVD Series for Immediate Use on Site (On-site Handbooks, Self-Learning, Employee Training Texts) ● Seminars (For Young and Mid-Career Employees / For Managers) ● Quality Improvement Support (Quality Improvement, New Product Launch, Contract Manufacturing)

![Pro Manual! Zero Defect Outflow Countermeasures Quality Improvement Techniques [Complete 8 Series]](https://image.mono.ipros.com/public/product/image/813/2000765622/IPROS35340332026041000038.jpeg?w=280&h=280)

![[Case Study] Kobayashi Manufacturing Co., Ltd.](https://image.mono.ipros.com/public/product/image/869/2000361957/IPROS4276185379211513833.jpg?w=280&h=280)