Achieving half price as usual! High-precision SLA resin "TSR-851"

Light-curing resin "TSR-851"

Low-cost, high-precision photopolymer resin "TSR-851"

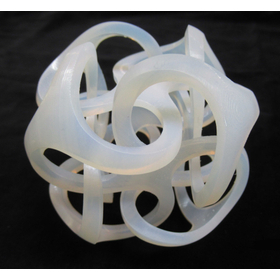

We have started selling the resin 'TSR-851', which enables high-precision and high-detail modeling at half the price of conventional light-curing resin. In recent years, with the spread of 3D printers, the available materials have become more advanced. As a result, the role of 3D printers in the manufacturing industry is becoming increasingly important. However, alongside this advancement, the prices of recent 3D printer materials have also risen significantly. On the other hand, many development sites in the manufacturing industry are being pressured to reduce development costs, leading to a clear need for lower material costs for 3D printers. Our new product, TSR-851, not only boasts excellent physical properties and quality but also realizes high precision and high detail that fully utilizes the performance of SLA, with a development theme of "providing it to the market at a lower price than any of our other materials!" We focused on achieving low cost in its development.

Inquire About This Product

basic information

Although it does not have outstanding specifications in terms of functionality, its moldability remains stable as before, and it is a resin capable of achieving the highest precision and detail in 3D printing. ◆Features of TSR-851 - High precision for casting masters - Moderate heat resistance - Best cost performance - A new proposal for price and accuracy ◆Price of TSR-851 16,500 yen/kg * Sold in units of 20kg. The 3D printing professional "C-MET" continues to provide innovative "technology," "products," and "services" at reasonable prices, allowing customers to use them with confidence, bringing to life what they have always wanted in their manufacturing services and technology.

Price information

Please feel free to contact us if you have any requests.

Delivery Time

Applications/Examples of results

- Master for silicone casting - Internal visualization (polishing process required) - Assembly evaluation test - Improved pre-treatment for painting

catalog(11)

Download All CatalogsNews about this product(3)

Company information

Our company has been engaged in the development of layered manufacturing devices, known as 3D printers, for 35 years this year, and as a pioneer in Japanese 3D printer development, we have worked for many years to contribute to the advancement of new technologies related to layered manufacturing. As a high-end industrial 3D printer manufacturer, our business policy since our founding has been to provide a "one-stop service" that encompasses equipment development, software development, resin development, and after-sales service. In recent years, the term for layered manufacturing devices has shifted from rapid prototyping (RP) to additive manufacturing (AM), particularly in Europe and the United States, and their application areas have evolved from simple shape verification to advanced testing and evaluation, as well as the realm of actual products and parts, with increasing applications for incorporation into mass-produced items. We specialize in selling high-end photopolymerization devices focused on shape verification, internal visualization, and assembly confirmation, which are emphasized in the early stages of development. We also sell sand mold layered manufacturing devices as tools for reducing lead times in the casting industry. Both of these devices are designed to meet the manufacturing needs of Japan, and we will continue to develop solutions that shape your needs in the future.

![Introduction to Light-Curable Resins [For Optoelectronics]](https://image.mono.ipros.com/public/product/image/51d/2001165958/IPROS65808532724650207723.jpeg?w=280&h=280)

![Notice of Participation in the 2nd Automotive World [Autumn]](https://image.mono.ipros.com/public/product/image/16d/2000926890/IPROS28985000015667160048.png?w=280&h=280)