Responding to extreme environments! Use powdered resol resin as the raw material for heat-resistant molded products.

Application examples of powder resoles for heat-resistant materials: As a raw material for "sintered bodies" that withstand high temperatures and high loads. It possesses excellent mechanical strength and chemical resistance.

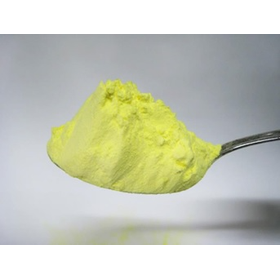

Powdered resol resin (pure resol) is a powdered form of resol-type phenolic resin with an extremely low amount of monomers. In addition to suppressing odor generation, it complies with regulations (not classified as a toxic substance under the Poisonous and Deleterious Substances Control Law). We offer a range of grades that provide various benefits such as improved workability and mixability, tailored to specific applications and requirements. This time, we would like to introduce a case study utilizing powdered resol resin in heat-resistant molded products (sintered bodies). 【Case Study】 Target: Raw material for sintered parts and heat-resistant molded products Role: A high-heat-resistant binder that binds powders such as ceramics and carbon Reason: After curing, it exhibits very high heat resistance, wear resistance, and chemical resistance, making it difficult to deform Effect: Dramatic improvement in the high strength and durability of parts, and ease of molding into complex shapes *For more details, please download the PDF or contact us.

Inquire About This Product

basic information

【Characteristics】 Shape: Powder form (white, light yellow to yellow-brown) Main component: Resole-type phenolic resin Solubility: Generally soluble in organic solvents Curing properties: Self-curing upon heating (no external catalyst required) Storage stability: Superior to liquid form, suitable for long-term storage

Price range

Delivery Time

Applications/Examples of results

■Casting industry: Binder for shell molds ■Brake materials: Friction material binder ■Electrical insulation materials: Molded products, insulation boards, etc. ■Adhesives: Wood-based materials, heat-resistant adhesives, etc. ■Heat-resistant materials: Binder for sintered bodies, raw materials for heat-resistant molded products

catalog(1)

Download All CatalogsCompany information

Phenolic resin, which has a history of about 100 years since it was introduced to the market. Lignite Co., Ltd. has transformed this phenolic resin into new forms. Our molded products range from small items weighing a few tens of grams to large items weighing about 160 kg, tailored to meet customer demands. Additionally, we offer unique products such as spherical phenolic resin (LPS) that has a rounded shape, and GPS and CFPS, which are phenolic resin-coated graphite and carbon fibers, respectively. Recently, we have been making daily progress towards the development and realization of new materials utilizing coating technology for various objects.

![Spherical phenolic resin [Good fluidity and high filling capacity] *Characteristic table available.](https://image.mono.ipros.com/public/product/image/62b/2000310086/IPROS8375492184728129058.jpg?w=280&h=280)

![[Example] Improved cutting performance by preventing blade contamination.](https://image.mono.ipros.com/public/product/image/c4f/2000644218/IPROS54051186879549803023.jpeg?w=280&h=280)

![[Example] Non-stick surface on metal = tape and glue will not adhere.](https://image.mono.ipros.com/public/product/image/94c/2000644550/IPROS96990920943492969297.jpeg?w=280&h=280)

![[Example] Non-stick property on metal surfaces = Prevention of dirt on photomasks](https://image.mono.ipros.com/public/product/image/646/2000645091/IPROS20008530851421665238.jpeg?w=280&h=280)