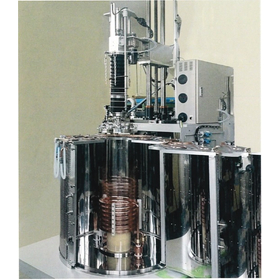

Continuous furnace for ceramics sintering (operating temperature 1,300°C)

This is an electric furnace used for firing ceramic molded products, operating at a regular temperature of 1,300°C. It is equipped with a hydraulic pusher at the entrance of the furnace, which pushes the products into the furnace at regular intervals. A sensor is incorporated at the exit of the furnace to notify the timing for product retrieval.

Inquire About This Product

basic information

This is an electric furnace used for firing ceramic molded products, operating at a regular temperature of 1,300°C. It is equipped with a hydraulic pusher at the entrance of the furnace, which pushes the products into the furnace at regular intervals. A sensor is incorporated at the exit of the furnace to indicate the timing for product retrieval.

Price information

-

Delivery Time

Applications/Examples of results

Firing of molded ceramic products.

Company information

We design, process, assemble, and install machines and equipment for use in temperature ranges from -170℃ to +1,700℃, as well as water treatment devices capable of dissolving various gases (such as oxygen, ozone, carbon dioxide, etc.) in water up to 99%. We also provide automatic feeding and extraction devices for the automation of various equipment, tailored to meet our customers' needs. We respond to customer requests regarding applications, installation space, budget, usability, and realize the desired equipment, including those that may have been previously given up on. Top Co., Ltd. is a manufacturer of industrial electric heating application equipment, designing and producing electric furnaces for metal melting and various types of dryers. In recent years, we have strengthened our efforts in the environmental sector. Since around 1996, we have started basic experiments on oilification and have been engaged in the oilification business with electric thermal pyrolysis devices. While many manufacturers have withdrawn, we have continued our oilification business, specializing in infectious waste. Since 2010, interest in oilification devices has increased, and we have received many inquiries.