Three-dimensional wafer-level packaging (WLP) is suitable for miniaturizing semiconductors. Through-silicon vias enable improvements in high-frequency characteristics.

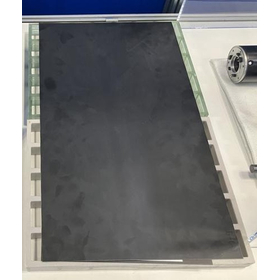

This product features numerous electrically conductive metal via-holes formed within borosilicate glass substrates such as Pyrex and Tempax. It can accommodate substrates up to a maximum diameter of 8 inches. It has good flatness and airtightness, making it suitable for anodic bonding for sealing silicon-based devices. 【Features】 ○ Capable of anodic bonding with silicon wafers Solves outgassing issues by enabling anodic bonding without the use of adhesives. ○ Excellent high-frequency characteristics - Ensures low stray inductance and low electrical resistance of vias. - Achieves high insulation compared to silicon by using glass as the base material. ○ Designed to function as a heat sink - Allows the vias to serve as thermal vias by incorporating silicon. ○ Transmits visible light - Enables confirmation of bonding points and transmission of optical signals. ○ Compatible with wafers up to Φ200mm. *For more details, please download the catalog or contact us.

Inquire About This Product

basic information

For other features and details, please download the catalog or contact us.

Price information

-

Delivery Time

Applications/Examples of results

【AV/Mobile】 - RF switches and relays for mobile devices (smartphones, handheld game consoles, digital cameras, car navigation), pressure sensors, gyro sensors, acceleration sensors, image sensors, etc. 【Semiconductors】 - RF-MEMS switches, etc. - Image sensors, etc. 【Automotive】 - Various pressure sensors, various acceleration sensors, etc. - Gyro sensors, etc. 【Bio-Medical】 - Medical pressure sensors, etc. 【Others】 - High-frequency switches (relays) - Various sensors (pressure, acceleration, gyro) - Biochips (for electrophoresis) - Microreactors (for bio sensors) - Optical device packages, etc. ● For more details, please contact us.

catalog(3)

Download All CatalogsNews about this product(1)

Company information

We will propose the most suitable solutions that match our customers' requirements, considering quality, cost, and mass production, through our advanced composite processing technology (Cross Edge Micro Machining), which combines five cutting-edge techniques: cutting, grinding, polishing, metalizing, and joining.

![Cross Edge Microfabrication [Glass Through Via Substrate (TGV)] Catalog](https://image.mono.ipros.com/public/catalog/image/01/54d/50849/IPROS3008310383844193583.JPG?w=120&h=170)

![Cross Edge Microfabrication Comprehensive Catalog [Latest Edition]](https://image.mono.ipros.com/public/catalog/image/01/d0a/317747/IPROS1997172726713350674.JPG?w=120&h=170)

![Cross-edge microfabrication [glass microfabrication]](https://image.mono.ipros.com/public/product/image/f97/319551004/IPROS_12284845090736490000.jpg?w=280&h=280)

![Cross-edge microfabrication [silicon products]](https://image.mono.ipros.com/public/product/image/3b7/319551005/IPROS_13836726167087188000.jpg?w=280&h=280)

![Cross-edge microfabrication [Ultra-pressure-resistant compact water-cooled heat sink]](https://image.mono.ipros.com/public/product/image/2d5/319551007/IPROS_13329095839829273000.jpg?w=280&h=280)

![Cross-edge microfabrication [microchannel cooler]](https://image.mono.ipros.com/public/product/image/22e/319551008/IPROS_15135300974487607000.jpg?w=280&h=280)

![[Purchase Page] Aluminum A5052 Cutting Gear Inventory Management Tottori](https://image.mono.ipros.com/public/product/image/0cd/2000537247/IPROS14231841269015898433.png?w=280&h=280)

![[Design Point] High-precision and burr-free resin cutting processing uses PPS.](https://image.mono.ipros.com/public/product/image/950/2001234056/IPROS36616210126830486622.jpeg?w=280&h=280)