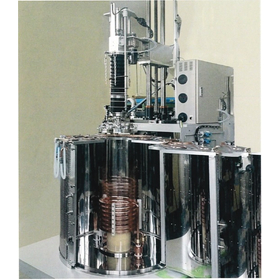

Aluminum continuous melting holding furnace - Preserve furnace

The furnace structure is further reinforced, demonstrating excellent combustion control! An aluminum continuous melting holding furnace with a structure that has no blind spots, making maintenance easy. 【Features】 - The combustion space in the holding chamber is large, with significant radiant heat. - The shallow and wide depth of the molten metal holding area allows for good heat absorption. - The selection of special refractory materials ensures good metal release. - Special high-alumina bricks are used in the floor of the melting chamber, achieving high strength and wear resistance. - The hot air from the holding chamber passes through the melting chamber and is discharged from the inlet, allowing for the preheating of materials. - The structure prevents cold materials from directly entering the molten metal, resulting in minimal temperature drop of the molten metal. - For controlling the temperature of the molten metal and the atmosphere inside the furnace, stability is maintained below the temperature range for oxide generation. - By adopting a radiant burner that emits a large amount of infrared radiation, significant heat absorption for aluminum is achieved, allowing for a lower setting of the atmosphere temperature inside the furnace, thereby reducing the generation of oxides that can cause hard spots. ● For other functions and details, please contact us.

Inquire About This Product

basic information

The furnace structure has been further strengthened, demonstrating excellent combustion control! An aluminum continuous melting holding furnace with a structure that has no blind spots, making maintenance easy. 【Features】 - The combustion space in the holding chamber is large, providing significant radiant heat. - The shallow and wide molten metal holding depth allows for good heat absorption. - The selection of special refractory materials ensures good metal release. - Special high-alumina bricks are used in the floor of the melting chamber, achieving high strength and wear resistance. - The hot air from the holding chamber passes through the melting chamber and is discharged from the inlet, allowing for utilization in material preheating. - The structure prevents cooling materials from directly entering the molten metal, resulting in minimal temperature drop of the molten metal. - For controlling the molten metal temperature and the atmosphere inside the furnace, stability is maintained below the temperature range for oxide generation. - The adoption of a radiant burner that emits a large amount of infrared radiation significantly increases heat absorption for aluminum, allowing for a lower setting of the atmosphere temperature inside the furnace, thereby reducing the generation of oxides that can cause hard spots. ● For other functions and details, please contact us.

Price information

-

Delivery Time

Applications/Examples of results

For more details, please contact us.

Company information

As technology advances at an accelerating pace, we do not want to forget the warmth of people and nature. Cutting-edge technology can sometimes feel inhumanly cold. However, the creation of new technology often starts with a small idea from a single person. Now that environmental issues are becoming more serious, no technology can be unrelated to nature. What can we, as developers of technology, do for people and nature? We are constantly challenging ourselves to create new technologies while considering such questions.