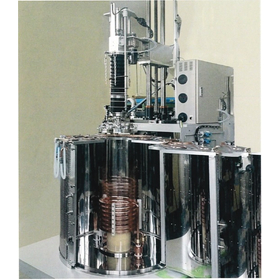

Commonly used/maximum temperature: 2000℃/2200℃! Vertical graphite furnace

This is an introduction to the "Vertical Graphite Furnace" handled by Marusho Denki, an expert company in electric furnaces, atmosphere furnaces, heating, and heat treatment technology. ■□■Features■□■ ■ The material of the furnace core tube can be adapted to various ceramics such as SUS, quartz, alumina, and carbon, depending on the usage temperature and atmosphere. ■ Options for high-precision atmosphere control, including temperature gradient specifications, high vacuum specifications, oxygen concentration control, dew point control, and program pressure control, are also available. ■ Internal dimensions: Ф60mm×H2000mm (Furnace core tube: Graphite tube) ■ Operating/maximum temperature: 2000℃/2200℃ ■ Heater: Graphite heater, vertical 3-zone control ■ For more details, please contact us.

Inquire About This Product

basic information

This is an introduction to the "Vertical Graphite Furnace" handled by Marusho Electric Co., a company specializing in electric furnaces, atmosphere furnaces, heating, and heat treatment technology. ■□■Features■□■ ■ The furnace core tube material can be adapted to SUS, quartz, ceramics such as alumina, carbon, etc., depending on the operating temperature and atmosphere. ■ A lineup of optional specifications including temperature gradient specifications, high vacuum specifications, oxygen concentration control, dew point control, and high-precision atmosphere control such as programmed pressure control. ■ Internal dimensions: Ф60mm×H2000mm (Furnace core tube: Graphite tube) ■ Operating/maximum temperature: 2000℃/2200℃ ■ Heater: Graphite heater, vertical 3-zone control ■ For more details, please contact us.

Price information

-

Delivery Time

Applications/Examples of results

■□■Usage■□■ SUS, quartz, alumina and other ceramics, carbon, etc.

catalog(1)

Download All CatalogsCompany information

Marusho Electric has been engaged in various heating devices by leveraging heater design technology, control technology, and a consistent system. In the cutting-edge technology fields we handle, such as FPD-related materials, electronic components, semiconductors, glass, fine ceramics, and CNT, there is a demand for highly advanced and precise heating and thermal processing technologies. For many years, we have utilized our advanced technical capabilities in these fields down to the finest details, and by consolidating them, we have made significant contributions to technological innovation and product development. What we take pride in is our technical capabilities that can meet various demands and our in-house integrated production system that supports them. Our exceptional technical capabilities and production system are highly regarded by many Japanese companies making strides in the world, and we are recognized as an important partner in their research, development, and production. Our motto is to continue making the utmost efforts in pursuit of "new dimensions" and "new creations." We will continue to challenge the new possibilities of "electric heating" with our wide-ranging experience, achievements, and insatiable curiosity, growing together with our customers who use our equipment.

![Horizontal tubular furnace [Oxygen concentration control type horizontal tubular furnace]](https://image.mono.ipros.com/public/product/image/952/68420006/IPROS_14526000408014283000.jpg?w=280&h=280)

![Horizontal tubular furnace [temperature gradient furnace]](https://image.mono.ipros.com/public/product/image/729/68420007/IPROS_13346956267344724000.jpg?w=280&h=280)

![Horizontal Tube Furnace [Horizontal High-Temperature Multi-Atmosphere Tube Furnace]](https://image.mono.ipros.com/public/product/image/246/68420008/IPROS_13156780389283578000.jpg?w=280&h=280)

![Vertical tubular furnace [Vertical high-temperature atmosphere tubular furnace]](https://image.mono.ipros.com/public/product/image/4ce/68420009/IPROS_15743033420986528000.jpg?w=280&h=280)

![Special Furnace [Vertical Multi-Atmosphere Furnace]](https://image.mono.ipros.com/public/product/image/2f6/68420020/IPROS_14114209340060324000.jpg?w=280&h=280)