Digital Ultrasonic Flaw Detector 'UI-180N'

Built-in probe switching function! Up to 4 channels can be switched.

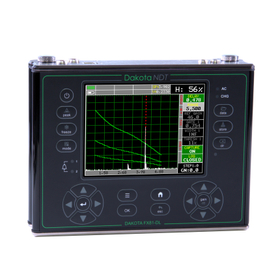

We would like to introduce our digital ultrasonic flaw detector, the 'UI-180N'. This product is designed for automatic inspection of welded parts from electron beam and laser beam processing machines, checking for welding depth, misalignment, blowholes, and cracks. It allows for the connection of an external VGA monitor, enabling the display of inspection results on a large screen. Please feel free to contact us if you have any inquiries. 【Features】 - The display uses a 6.4-inch TFT color LCD to enhance visibility. - It is possible to connect an external VGA monitor. - It has a built-in transducer switching function, allowing for switching up to 4 channels. - The interface specifications with the control panel are compatible with the UI-180. - The operation keys on the panel are displayed in Japanese, improving usability for setting inspection conditions and other operations. *For more details, please refer to the PDF document or feel free to contact us.

- Company:菱電湘南エレクトロニクス 検査計測事業

- Price:Other

![[Data] Reliability of Non-Destructive Testing](https://image.mono.ipros.com/public/product/image/4ed/2001255465/IPROS30366797801464297248.png?w=280&h=280)

![[Data] Measurement Method for Probe Delay Time (Method for Setting Probe Entry Point)](https://image.mono.ipros.com/public/product/image/922/2001255474/IPROS16722677899381348992.png?w=280&h=280)

![[Information] A Discussion on Ultrasonic Testing Equipment <Basic Edition>](https://image.mono.ipros.com/public/product/image/ae0/2001255477/IPROS65318010306575239434.png?w=280&h=280)

![[Information] Notice regarding the common AC adapter for the UI series.](https://image.mono.ipros.com/public/product/image/b7c/2001520946/IPROS1178573597708799982.jpg?w=280&h=280)