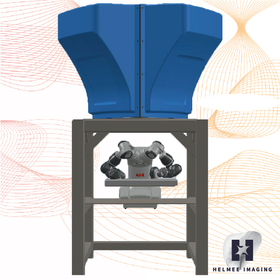

Composite Macro-Micro Review Inspection Device (with Laser Marking)

Introducing an inspection device compatible with 6 and 8-inch wafers, equipped with laser marking.

This product is a device equipped with laser marking and marker counting functions for macro-micro inspection systems. The macro unit, micro unit, and laser marking chamber are supplied with wafers automatically by a transport unit. It allows for macro visual observation and micro microscopic observation, and can perform automatic laser marking at specified coordinates in conjunction with a higher-level system. 【Features】 ■ Compatible with 6 and 8-inch wafers ■ Equipped with laser marking and marker counting functions ■ Capable of macro visual observation and micro microscopic observation ■ The macro unit, micro unit, and laser marking chamber are automatically supplied with wafers by a transport unit ■ Can perform automatic laser marking at specified coordinates in conjunction with a higher-level system *For more details, please refer to the PDF document or feel free to contact us.

- Company:アテル

- Price:Other

![[Basic Data] Application of Deep Learning to Visual Inspection](https://image.mono.ipros.com/public/product/image/861/2000506859/IPROS32986063125599993519.jpeg?w=280&h=280)

![[Case Studies of Automation] Inspection Equipment / Embedded Devices / Winding Machines](https://image.mono.ipros.com/public/product/image/073/2000651677/IPROS09032114155894794534.png?w=280&h=280)