Do you know that aluminum material can be barrel plated?

Cost reduction may be possible! Enabling barrel plating for aluminum materials, which has traditionally been considered difficult.

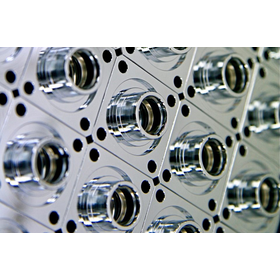

Are you under the impression that aluminum materials such as ADC12 and A5052 can only be surface treated with anodizing? Or do you think that aluminum materials can only be plated using a jig for hook plating? Silvec has made barrel plating on aluminum materials, which has traditionally been considered difficult, possible. 【Features】 ○ Significant cost reduction → No costs for jig manufacturing or labor costs for jig setup ○ No need to set the workpiece in a jig ○ Improved corrosion resistance → No contact marks from jig setup on the workpiece → No corrosion from contact marks ○ Very advantageous for dimensional control of the workpiece after plating → Less variation in plating thickness between workpieces compared to hook plating ○ Conductivity → Unlike anodizing, most of the plating film conducts electricity well ○ Choice of specifications → Various coatings that can be soldered are available For more details, please contact us or refer to the catalog.

- Company:シルベック 本社工場

- Price:Other

![[Presentation of Materials] Value Enhancement Strategies for Zinc Die-Cast Products through Plating and Surface Treatment](https://image.mono.ipros.com/public/product/image/e7d/2000567729/IPROS55584449244459034306.png?w=280&h=280)

![[Information] Enhancing the Value of Aluminum Products through Plating and Surface Treatment](https://image.mono.ipros.com/public/product/image/fef/2000567795/IPROS53914575237167008446.jpeg?w=280&h=280)

![[Data] In-vehicle high-speed transmission system connector standards FAKRA/USCAR](https://image.mono.ipros.com/public/product/image/f78/2000569681/IPROS11623070662703667945.jpeg?w=280&h=280)

![[Case Study] Functional Feature Improvement Case](https://image.mono.ipros.com/public/product/image/ddc/2000569706/IPROS02334005932725292659.jpeg?w=280&h=280)

![[Case Study] Quality Improvement Case](https://image.mono.ipros.com/public/product/image/401/2000569713/IPROS95358914902010600150.jpeg?w=280&h=280)

![[With video] Plating for hardware on automotive entry keys](https://image.mono.ipros.com/public/product/image/e13/2000718604/IPROS95569613220243815100.png?w=280&h=280)