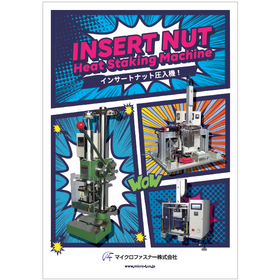

[Custom Machine Production Example] Press-in Machine

We take responsibility for supporting our customers even in after-sales service! Let us introduce our production examples.

We would like to introduce a case study of the "press-fitting machine" that we manufacture. We produce pin press machines, high-temperature high-pressure adhesive machines, 50-ton press machines, and bearing press-fitting machines. After delivering the machines, we provide a one-year warranty. In the unlikely event of a malfunction, we will respond quickly and reliably. Please feel free to consult us when you need our services. 【Case Overview】 ■Product Achievements - Pin press machine - High-temperature high-pressure adhesive machine - 50-ton press machine - Bearing press-fitting machine *For more details, please refer to the PDF document or feel free to contact us.

- Company:成興技研

- Price:Other

![[Custom Machine Production Example] Press-in Machine](https://image.mono.ipros.com/public/product/image/1ec/2001158600/IPROS39061169340695920434.png?w=280&h=280)

![[Development Case] Bearing Press-in Device](https://image.mono.ipros.com/public/product/image/3c0/2000938918/IPROS81274057396435673432.png?w=280&h=280)

![[Materials for Design and Production Engineers] Basic Knowledge of Press-Fitting and Press-Fitting Equipment](https://image.mono.ipros.com/public/product/image/ef6/2000492154/IPROS13367724687194885238.png?w=280&h=280)