Yokota Corporation "Company Profile"

Become a company that can contribute to the local community - fostering 'vibrant human beings'.

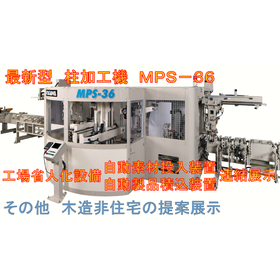

Yokota Corporation is located in Yoshinogawa City, Tokushima Prefecture, and engages in bearing race turning and automotive parts turning processing. Our roots trace back to the late Meiji period with the "sale of indigo fabric" in Hokkaido and the "manufacture and sale of herring residue" directed towards Tokushima. Subsequently, our predecessor quickly grasped the "changes of the times" and established the company as a bearing turning processing business. For over 50 years since then, in addition to our mainstay of bearing turning, we have recently also been involved in the processing of various automotive parts (including transmissions). Moving forward, we will continue to provide better products and services to our customers through the development of people, striving to ensure that the local community recognizes our significance. 【Business Activities】 ■ Bearing race turning processing, automotive parts turning processing ■ Design, manufacturing, and sales of automated machines, automatic inspection machines, hydraulic single-function machines, and NC lathes ■ Operation of a reuse store (franchise member) and a home center ■ Housing-related businesses such as new construction and renovations (related company: Yokota Home) *For more details, please refer to our catalog or feel free to contact us.

- Company:ヨコタコーポレーション

- Price:Other

![[Example] Ultra-high precision micro-machining <Micron-level cutting processing on metal cross-sections>](https://image.mono.ipros.com/public/product/image/d0d/2000918051/IPROS05351711356039695616.png?w=280&h=280)

![[Technology News Vol. 2] Introduction of New Equipment: Lathe and Electric Discharge Machine](https://image.mono.ipros.com/public/product/image/a9d/2000424419/IPROS1443887062920782347.jpg?w=280&h=280)

![[Case Study: Manufacturing Subsidy] Establishment of High-Precision Processing for Multi-Joint Robot Parts](https://image.mono.ipros.com/public/product/image/5f9/2000734483/IPROS30751437002482427250.png?w=280&h=280)

![CNC Wire EDM Precision Contour Machine [Ideal for Separation Processing!]](https://image.mono.ipros.com/public/product/image/963/2000295865/IPROS36151506677134855031.png?w=280&h=280)