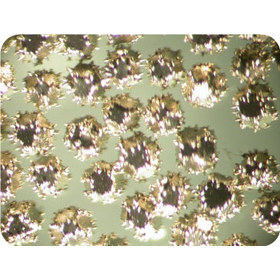

Cr Coating (Chrome Coating)

The coating layer protects the diamond in high-temperature environments, preventing corrosion and graphitization.

Chromium has excellent wettability and affinity, so it forms chromium carbide on the surface of diamond abrasives through sintering. This chromium carbide enhances the retention of diamond abrasives and increases the bonding strength between the abrasives and the bond. Furthermore, the chromium coating improves the strength and corrosion resistance of the diamond abrasives.

- Company:鄭州多磨超硬材料有限公司(ZZDM SUPERABRASIVES CO.,LTD)

- Price:Other

![[Europe] High corrosion-resistant surface treatment non-chrome zinc flake coating](https://image.mono.ipros.com/public/product/image/4bc/2000845650/IPROS00328874011219841208.jpeg?w=280&h=280)

![[Automotive Industry Case Study] Release Properties + Wear Resistance + Image Recognition Properties 'Bicoat'](https://image.mono.ipros.com/public/product/image/9d7/2000610970/IPROS10482704936023872394.png?w=280&h=280)

![[Automotive Industry Case] Mold Parts Release Surface Treatment - Strong Non-Stick Coating](https://image.mono.ipros.com/public/product/image/5a2/2000609107/IPROS24323972418433932162.jpeg?w=280&h=280)

![[Research Material] The Global Market for Synthetic Resin Coatings](https://image.mono.ipros.com/public/product/image/2a8/2001459078/IPROS10423369070924320895.jpeg?w=280&h=280)

![[Research Material] Global Market for Inorganic Waterproof Coatings](https://image.mono.ipros.com/public/product/image/8a6/2001474238/IPROS49868365252821124262.jpeg?w=280&h=280)

![[Research Material] Global Market for Wood Preservation Coatings](https://image.mono.ipros.com/public/product/image/22c/2001474248/IPROS02685380574538315801.jpeg?w=280&h=280)