A liquid coating device that utilizes centrifugal force. Ideal for applying release silicone, anti-fog agents, and anti-static agents to various plastic sheets such as PET and PS!

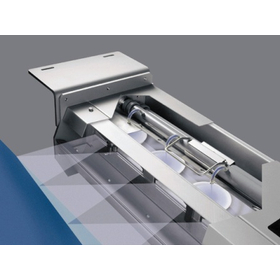

The "WEKO Rotor Dumping" applies the coating liquid in a thin fan-shaped mist picked up by a rotor that rotates at high speed driven by a belt. The overall application width is determined by the number of rotors, the basic application amount is based on the rotor type, and the ON/OFF of the spray application is controlled by the opening and closing of a shutter. Features such as easy control of the application amount, quick responsiveness to changes in application amount, uniform application, and non-contact application have been well received, and it is widely used not only in Japan but also in many countries around the world for applying release silicone, anti-fog agents, and anti-static agents to plastic sheets. Additionally, due to unique features not found in other application devices, it is adopted in various industries beyond plastics, including paper, textiles, non-woven fabrics, and wood. For more details, please download the catalog or contact us.

【Exhibition Information】

■Exhibition Name: High-Functionality Materials Week

■Date: November 12-14, 2025

■Time: 10:00 AM - 6:00 PM

■Venue: Makuhari Messe

■Participation Fee: Free for pre-registered attendees

■Booth Number: 15-1 (Hall 3)