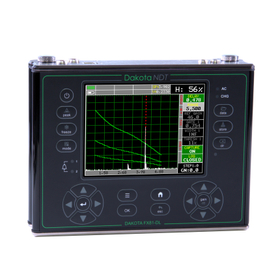

A high-performance ultrasonic flaw detector with excellent versatility, equipped with a Blanview LCD display that offers outstanding visibility even in sunlight.

The DFX-8 series is a high-performance ultrasonic flaw detector that can be used for a wide range of applications, from detecting welds to measuring high-damping materials such as castings and FRP, as well as thick materials. It is equipped with all the necessary functions for ultrasonic testing, including DAC (Distance Amplitude Correction), TCG, DGS/AVG, and curved surface correction. With a robust aluminum body, dust and drip-proof design (compliant with IP65), and a Blanview LCD display that ensures excellent visibility even in sunlight, it can be safely used outdoors.

The higher model, DFX-8+, includes a 400V tone burst, narrowband filters at 0.5MHz and 15MHz, an interface gate for immersion testing, and external control and data output functions that enable automatic inspection on the production line.

■ Features

- Blanview display that is easy to read outdoors

- An astonishing measurement range of approximately 30m (equivalent to steel)

- High-resolution measurement mode with a display accuracy of 0.001mm, ensuring high precision

- All functions of the top model ultrasonic thickness gauge "CMX DL+" are standard

- Supports operation with batteries, AC power, and dry batteries

*For more details, please refer to the PDF document or contact us.

- Company:ダコタ・ジャパン

- Price:500,000 yen-1 million yen

![[Data] Reliability of Non-Destructive Testing](https://image.mono.ipros.com/public/product/image/4ed/2001255465/IPROS30366797801464297248.png?w=280&h=280)

![[Data] Measurement Method for Probe Delay Time (Method for Setting Probe Entry Point)](https://image.mono.ipros.com/public/product/image/922/2001255474/IPROS16722677899381348992.png?w=280&h=280)

![[Information] A Discussion on Ultrasonic Testing Equipment <Basic Edition>](https://image.mono.ipros.com/public/product/image/ae0/2001255477/IPROS65318010306575239434.png?w=280&h=280)

![[Information] Notice regarding the common AC adapter for the UI series.](https://image.mono.ipros.com/public/product/image/b7c/2001520946/IPROS1178573597708799982.jpg?w=280&h=280)