1~45 item / All 1739 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~45 item / All 1739 items

Filter by category

In the manufacturing industry, have you ever experienced situations like "there's a labor shortage, but when a newcomer arrives, there's no time to teach them" or "I don't know where to start teaching"? The "Matsui Manufacturing Channel," focused on manufacturing education, covers a wide range of topics, including specialized knowledge such as NC lathe programming and geometric tolerances like flatness, as well as concepts in quality control, inventory management, workplace communication, and attitudes towards work. 【Target Audience】 - Newcomers - Those who have recently changed departments or positions - Those who have recently become supervisors and need to manage areas outside their expertise Some videos are equipped with subtitles in the following foreign languages, and we hope that individuals with specific skills or trainees will find them useful. 【Subtitle Languages (for some videos)】 English, Chinese, Vietnamese, Burmese, Thai, Nepali, Hindi, Bengali

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

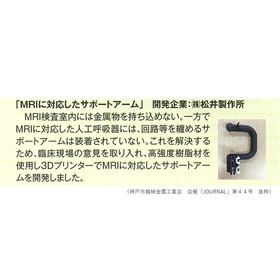

Metal objects cannot be brought into the MRI examination room. On the other hand, the ventilators compatible with MRI do not have support arms to organize the circuits. To solve this issue, we incorporated feedback from clinical settings and developed a support arm compatible with MRI using high-strength resin materials and a 3D printer.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Have you ever been told while working, "Think about cost-effectiveness in your work"? While this is a common phrase, haven't you ever wondered, "What specifically should I consider and how?" In this video, we will explain some typical examples of cost-effectiveness.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When you are working, do you ever find yourself troubled by the thought, "I want to solve the problem in front of me, but I don't know where to start"? In this video, we will introduce a way of thinking that can help organize your thoughts: a diagram of causes and effects.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Have you ever struggled with whether to use an NC lathe or a machining center for processing on the cutting machining site? In this video, we will introduce some helpful ways of thinking.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When you work at a company, you often find yourself collaborating with various people. Have you ever struggled with thoughts like, "I want to determine the direction of my department, but I don't know where to start..." or "I'm working hard, but I'm not seeing the results..."? Such issues may arise from a narrow perspective. In previous videos, we introduced the matrices of [Individual/Organization × Inner/Outer] and [Concrete/Abstract × Flow/Stock], and we explored techniques for organizing thoughts. In this video, we will introduce different ways of thinking using various matrices. - Inability to objectively recognize the current situation - Thinking only within the limits of past experiences and established values - Focusing solely on sporadic symptomatic treatments If you are struggling with these issues, I encourage you to take a moment to pause and try the methods explained in this video.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When you work at a company, you often find yourself working with various people. In that context, have you ever struggled with feelings like "I'm so caught up in my current tasks that I can't really feel my growth..." or "I'm working hard, but for some reason, I'm not seeing any results..."? These issues may stem from a narrow perspective. In this video, I will introduce one specific method for broadening your perspective: the 【Concrete/Abstract × Flow/Stock Matrix】. - You can only think within the limits of your past experiences and established values. - You often find yourself going in circles. - You have difficulty coming up with good solutions. If you are facing such challenges, I encourage you to take a moment to pause and try the method being explained this time.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When you work at a company, you often collaborate with various people. In that context, have you ever struggled with situations like, "I thought I was doing the right thing, but it didn't go well because my understanding was misaligned with my boss or people from other departments..." or "When trying to decide on a policy within the team, for some reason, we couldn't come to a consensus, and it ended up being an ambiguous conclusion..."? These issues may arise from a narrow perspective. In this video, I will introduce one specific method for broadening your perspective: the [Individual/Organization × Internal/External Matrix]. - You can only judge things within the scope of your own experiences and values. - You can only come up with partial solutions. - You overlook other people's viewpoints. If you are struggling with such issues, I encourage you to take a moment to stop and try the method explained in this video.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"I want to improve production efficiency and achieve results even within a limited time. However, I don't know how to think about it specifically." Do you have such concerns in workplaces like offices or factories? In this video, we will explain the concept of "hypothetical thinking and structuring problems." If you want to solve problems and move your work forward but don't know how to proceed, or if you feel like time is just passing by, please take a look!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Want to improve production efficiency and achieve results even within a limited time? But I don't know how to think about it concretely." Do you have such concerns in workplaces like offices or factories? In this video, we will explain the concept of "variables and constants." The terms "variables" and "constants" may be familiar from mathematics, but here we define "variables: things that can be changed by one's own efforts" and "constants: things that cannot be changed by one's own efforts." How can we apply this concept of "variables" and "constants" to work? Please watch the video for more details.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the manufacturing industry, accurate estimation of prices is crucial for improving yield. Understanding the method of calculating labor rates, in particular, forms the foundation of cost management. If labor rates are not calculated correctly, it can pressure profits and negatively impact management. This video explains the basic concepts of labor rates and suggests ways to enhance the transparency of estimation prices. 【Usage Scenarios】 - When creating estimates for new products - When aiming for cost reduction - When wanting to review the method of calculating labor rates 【Effects of Implementation】 - Accurate estimation of prices - Improved cost management capabilities - Enhanced profit margins

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the energy industry, appropriate supply adjustments are required to respond to demand fluctuations. Excess inventory leads to increased costs, while shortages heighten the risk of supply interruptions. Efficient inventory management is essential for balancing stable supply and cost reduction. This video explains the mechanisms behind inventory accumulation through simulation, clearly outlining the causes and countermeasures. 【Usage Scenarios】 - Inventory management of fuel and parts at power companies - Parts management of supply equipment at gas companies - Parts management at renewable energy-related companies 【Benefits of Implementation】 - Mitigation of cost increases due to excess inventory - Reduction of supply interruption risks - Establishment of an efficient inventory management system

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the logistics industry, optimizing transportation efficiency is crucial. Excess inventory can lead to pressure on storage space and increased transportation costs, which may ultimately squeeze profits. This video simulates the mechanisms behind inventory accumulation, clarifying its causes and countermeasures. If you are facing challenges in inventory management or want to improve transportation efficiency, please take a look. 【Usage Scenarios】 - Optimization of inventory management - Reduction of transportation costs - Effective use of warehouse space 【Effects of Implementation】 - Improvement in inventory management - Reduction of unnecessary costs - Enhancement of operational efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, proper inventory management of components is essential for cost reduction and adherence to delivery deadlines. Excess inventory can increase storage costs and strain cash flow, while insufficient inventory can lead to production delays and risk damaging customer trust. This video simulates the mechanisms behind inventory accumulation and provides tips for solving inventory management challenges. 【Usage Scenarios】 * Component procurement departments of electronics manufacturers * Inventory management personnel * Production management departments 【Benefits of Implementation】 * Improvement in inventory management * Reduction of obsolete inventory * Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive parts industry, maintaining an appropriate inventory level is crucial. Excess inventory can increase storage costs and strain cash flow. On the other hand, insufficient inventory can lead to production line stoppages and the risk of delayed deliveries to customers. This video explains the mechanisms behind inventory accumulation through simulation and provides tips for solving inventory management challenges. Be sure to check it out! 【Usage Scenarios】 - Inventory management of automotive parts - Reduction of obsolete inventory 【Benefits of Implementation】 - Streamlining inventory management - Potential cost reduction - Improvement in productivity

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are wholesalers feeling challenges with inventory management? Excess inventory can lead to increased storage costs and worsened cash flow, becoming a burden on management. This video clearly explains the mechanisms behind inventory accumulation through simulation. We hope it helps you improve your inventory management. 【Usage Scenarios】 - Optimization of inventory management - Reduction of obsolete inventory - Efficiency improvement across the entire supply chain 【Effects of Implementation】 - Visualization of inventory management challenges - Consideration of improvement measures for inventory management - Enhancement of operational efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the retail industry, appropriate ordering and inventory management are crucial to respond to demand fluctuations. Excess inventory can increase storage costs and strain cash flow. On the other hand, insufficient inventory can lead to lost sales opportunities. This video explains the mechanisms behind inventory accumulation through simulation and provides information that helps improve the accuracy of order forecasting. 【Usage Scenarios】 - Streamlining ordering operations - Reviewing inventory management - Reducing obsolete inventory 【Effects of Implementation】 - Optimization of inventory management - Cost reduction - Improvement of profit margins

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the optimization of manufacturing processes, inventory management is an important issue. Many companies are struggling with increasing inventory and rising management costs. This video clearly explains the mechanisms behind inventory accumulation through simulation. Please use it to understand the challenges of inventory management and find improvement measures. 【Usage Scenarios】 * Manufacturing companies feeling challenges in inventory management * Companies wanting to reduce excess inventory * Companies aiming for optimization of the entire supply chain 【Effects of Implementation】 * Visualization of inventory management challenges * Tips for specific measures to reduce inventory * Overall efficiency improvement of the supply chain

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the wood processing industry, it is important to suppress the occurrence of defective products in order to maintain product quality and improve yield. In particular, cracks during the drying and processing stages not only diminish the value of the products but also lead to complications in inventory management and increased costs. This video focuses on reducing defective products and explains the basics of inventory management. 【Usage Scenarios】 - Reducing defective products in processes where wood is prone to cracking - Streamlining inventory management - Improving product quality 【Effects of Implementation】 - Cost reduction through the reduction of defective products - Optimization of inventory management - Increased customer satisfaction due to improved product quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the glass industry, the inclusion of bubbles that affects product quality is a significant challenge. The occurrence of defective products leads to increased inventory and higher costs. This video explains the reduction of defective products as a fundamental aspect of inventory management. 【Usage Scenarios】 * Reduction of defective products in the manufacturing process of glass products * Optimization of inventory management 【Benefits of Implementation】 * Cost reduction through the reduction of defective products * Increased efficiency in inventory management * Improvement in product quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the metal processing industry, dimensional accuracy is a crucial factor that affects product quality. Inadequate dimension management can lead to the occurrence of defective products, resulting in increased inventory and costs. This video explains the reduction of defective products as a fundamental aspect of inventory management. 【Usage Scenarios】 * Reduction of defective products in metal processing * Improvement of inventory management * Enhancement of dimensional management accuracy 【Benefits of Implementation】 * Cost reduction through the reduction of defective products * Streamlining of inventory management * Gaining trust from customers

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the semiconductor manufacturing industry, it is important to maintain cleanliness and minimize the occurrence of defective products. The emergence of defective products can lead to reduced yield and increased costs, potentially undermining a company's competitiveness. In inventory management, the occurrence of defective products can cause excess inventory, leading to pressure on storage space and increased disposal costs. This video focuses on reducing defective products and proposes improvements in inventory management. 【Usage Scenarios】 - Inventory management department of semiconductor manufacturing plants - Quality control department - Improvement personnel on the manufacturing floor 【Benefits of Implementation】 - Optimization of inventory through the reduction of defective products - Cost reduction - Quality improvement

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, high precision of components is required to ensure product safety and reliability. Particularly for parts used in harsh environments, it is important to minimize the occurrence of defective products. The emergence of defects can lead not only to increased costs but also to a decrease in safety. This video explains the reduction of defective products as a fundamental aspect of inventory management. 【Usage Scenarios】 * Manufacturing of aerospace components * Improvement of quality control * Optimization of inventory management 【Effects of Implementation】 * Reduction of defective products * Reduction of inventory costs * Improvement of product quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, improving yield directly translates to profit. The occurrence of defective products leads to increased costs and is a factor that reduces competitiveness. Optimizing inventory management is essential to suppress the occurrence of defects and improve yield. In this video, we will explain the reduction of defective products as a fundamental aspect of inventory management. 【Usage Scenarios】 - Inventory management in electronics manufacturing - Want to reduce the defect rate - Want to reduce inventory costs 【Effects of Implementation】 - Reduction of defective products - Streamlining of inventory management - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, reducing defective products is essential to provide high-quality products. The occurrence of defects not only undermines customer trust but also increases repair costs and the risk of recalls, negatively impacting the company's performance. This video explains the reduction of defective products as a fundamental aspect of inventory management. 【Usage Scenarios】 * Want to improve the defect rate in the manufacturing process of automotive parts * Aim to streamline inventory management * Want to strengthen quality control systems 【Benefits of Implementation】 * Cost reduction through the reduction of defective products * Improvement in customer satisfaction * Enhancement of the company's brand image

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the furniture manufacturing industry, streamlining material procurement directly leads to cost reduction and shorter delivery times. Particularly when the procurement lead times for materials such as wood and metal parts are long, it can lead to complicated inventory management and delays in production planning. This video explains how to shorten production lead times and provides information that can help improve inventory management. 【Usage Scenarios】 * Inventory management in the procurement of materials such as wood and metal parts * Wanting to prevent delays in production planning * Aiming for cost reduction 【Benefits of Implementation】 * Reduction in inventory costs * Prevention of shortages of necessary products * Improvement in production efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the energy industry's equipment maintenance, proper parts management is essential for stable operation of equipment. Excess inventory can lead to increased costs, and a shortage of necessary parts may result in equipment downtime. Reducing production lead times contributes to more efficient inventory management and helps address these challenges. 【Usage Scenarios】 - Parts procurement for regular equipment maintenance - Response to unexpected failures - Reduction of excess inventory of parts 【Benefits of Implementation】 - Ability to procure necessary parts when needed - Reduction of inventory costs - Improvement of equipment operating rates

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the metal processing industry, there is always a demand for shorter delivery times and cost reductions. In particular, optimizing processing time is a crucial challenge for improving production efficiency. Reducing production lead times also contributes to better inventory management, ultimately leading to cost savings. This video explains the reduction of production lead times as a fundamental aspect of inventory management. [Usage Scenarios] * Shortening processing time in the manufacturing of metal products * Streamlining inventory management [Effects of Implementation] * Shorter delivery times * Cost reductions * Improved inventory management

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the logistics industry, improving transportation efficiency is always a priority. In particular, optimizing inventory management is a crucial issue that directly relates to reducing transportation costs. Excess inventory can lead to pressure on storage space and increased management costs, while insufficient inventory can result in lost opportunities. This video explains the shortening of production lead times as a fundamental aspect of inventory management in the manufacturing sector, which can help improve inventory management in logistics. 【Usage Scenarios】 - Optimization of inventory management - Reduction of transportation costs - Effective use of storage space 【Effects of Implementation】 - Proper inventory levels - Cost reduction - Improved operational efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the machinery manufacturing industry, effective deadline management is crucial to meet the diverse needs of customers. A long production lead time can lead to delays in delivery and increased inventory, potentially resulting in decreased customer satisfaction and higher costs. This video explains the shortening of production lead times as a fundamental aspect of inventory management. 【Usage Scenarios】 - Companies facing challenges in deadline management - Companies aiming to reduce inventory - Companies looking to improve production efficiency 【Benefits of Implementation】 - Mitigation of the risk of delivery delays - Reduction of inventory costs - Improvement in customer satisfaction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, the quality and delivery time of parts are extremely important. In parts supply, optimizing inventory is essential. Reducing production lead time is crucial for improving inventory turnover, reducing storage costs, and supplying the necessary parts when needed. This video explains the reduction of production lead time as a fundamental aspect of inventory management. 【Usage Scenarios】 * Manufacturing of aerospace parts * Inventory management in parts supply * Delivery time management 【Benefits of Implementation】 * Reduction of inventory costs * Timely supply of necessary parts * Decreased risk of stockouts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, streamlining the manufacturing process is essential for cost reduction and shortening delivery times. Particularly, in the context of increasing component counts and more complex processes, long production lead times can lead to increased inventory and potential opportunity losses. This video explains the shortening of production lead times as a fundamental aspect of inventory management. 【Usage Scenarios】 - Inventory management in the manufacturing process of electronic devices - Reducing lead times from component procurement to manufacturing and delivery 【Benefits of Implementation】 - Reduction in inventory costs - Stabilization of product supply systems - Improvement in customer satisfaction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the field of automotive parts procurement, issues such as excess inventory and stockouts can arise. The length of production lead time increases the difficulty of inventory management and is one of the factors that generates extra costs. This video explains the shortening of production lead time as a fundamental aspect of inventory management. By reducing production lead time, it leads to a decrease in inventory costs and ensures the availability of necessary parts. Our video materials contribute to solving inventory management challenges in automotive parts procurement. 【Usage Scenarios】 - Parts procurement departments of automotive manufacturers - Supply chain management departments - Inventory management personnel 【Benefits of Implementation】 - Reduction in inventory costs - Decrease in stockout risks - Improvement in production efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the energy industry, the diversification of materials used in piping can lead to complexities in inventory management. Particularly when using a wide variety of piping components, it is easy to experience either excess or shortages in inventory, which can result in increased costs. This video explains the standardization of materials as a fundamental aspect of inventory management in manufacturing. [Usage Scenarios] - Inventory management of piping components - Cost reduction - Inventory optimization [Benefits of Implementation] - Reduction in inventory costs - Stable supply of products - Improvement in operational efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the robotics industry, the diversification of sensor components and the resulting complexity in inventory management have become challenges. Particularly for robots that require high-precision sensors, the procurement and inventory management of components significantly impact product quality and cost. Optimizing inventory management is crucial for enhancing product competitiveness. This video explains the standardization of materials as a fundamental aspect of inventory management. 【Usage Scenarios】 * Inventory management of robot sensor components * When there are many types of components, making management complicated * When wanting to reduce inventory costs 【Effects of Implementation】 * Reduction in inventory costs * Reduction in component procurement costs * Improvement in product quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the furniture industry, the management of hardware inventory significantly impacts product quality and delivery times. Particularly, to accommodate a variety of designs and sizes of furniture, the types of hardware tend to increase, making inventory management more complex. Excess inventory can lead to pressure on storage space and increased costs, while insufficient inventory may cause production delays. This video will explain the standardization of components as a fundamental aspect of inventory management in manufacturing. 【Usage Scenarios】 - Furniture manufacturers - Personnel responsible for hardware inventory management - Companies aiming for cost reduction 【Benefits of Implementation】 - Reduction in inventory costs - Stable supply of products - Improvement in operational efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the machine tool industry, managing a diverse range of components can be a challenge in unit manufacturing. Issues such as increased inventory costs and shortages of necessary components can lead to decreased production efficiency. This video explains the standardization of components as a fundamental aspect of inventory management in manufacturing. Standardizing components contributes to inventory optimization and the establishment of an efficient production system. 【Usage Scenarios】 * Inventory management in unit manufacturing of machine tools * Procurement of components in small-batch, high-variety production * Companies aiming for cost reduction 【Benefits of Implementation】 * Reduction in inventory costs * Rapid procurement of necessary components * Improvement in production efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, the diversification of components and the complexity of inventory management have become challenges. In particular, to meet the diverse needs of products, it is necessary to hold many types of components, which can lead to issues such as increased inventory costs and shortages of necessary parts. This video explains the standardization of materials as a fundamental aspect of inventory management in manufacturing. Standardizing materials is an effective means of reducing the variety of inventory and lowering management costs. 【Usage Scenarios】 - Inventory management departments of electronics manufacturers - Procurement personnel for components - Personnel in the manufacturing department 【Benefits of Implementation】 - Reduction in inventory costs - Improved efficiency in component procurement - Decreased risk of stockouts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the medical device industry, compatibility of components is crucial to ensure the reliability and safety of products. In particular, medical devices often have various standards and specifications, making the procurement and inventory management of components complex. By considering the compatibility of materials, it leads to optimization of inventory and cost reduction. This video explains the standardization of materials as a fundamental aspect of inventory management. 【Usage Scenarios】 - Component procurement in medical device manufacturing - Component replacement during repair and maintenance - Responding to a diverse product lineup 【Effects of Implementation】 - Reduction in inventory costs - Decrease in component procurement costs - Stable supply of products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, product quality and safety are the top priorities, and compliance with strict standards is required. Adhering to standards is also a significant challenge in parts procurement and inventory management. Optimizing inventory management contributes not only to cost reduction but also to maintaining quality. This video explains the standardization of materials as a fundamental aspect of inventory management. 【Usage Scenarios】 * Manufacturing aerospace components * Parts management in compliance with standards * Reducing inventory costs 【Benefits of Implementation】 * Cost reduction through inventory optimization * Stable supply of compliant parts * Improvement in quality management

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the home appliance industry, product diversification has become a challenge alongside inventory management of parts. Particularly, using different parts for multiple products can increase the variety of inventory and potentially raise management costs. Standardizing materials is an effective means to reduce the types of inventory and streamline management. This video explains the standardization of materials as a fundamental aspect of inventory management. 【Usage Scenarios】 * Design and manufacturing departments of home appliances * Inventory management departments * Companies aiming for cost reduction 【Effects of Implementation】 * Reduction in inventory value * Decrease in procurement costs for parts * Streamlining of inventory management operations

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive module industry, inventory management tends to become complicated due to the large number of parts. In particular, addressing the diverse range of vehicle models and options poses challenges in ensuring adequate inventory levels and securing storage space. Standardizing components is crucial for solving these issues and achieving efficient inventory management. This video explains the concept of component standardization as a fundamental aspect of inventory management. 【Usage Scenarios】 * Inventory management in automotive module manufacturing * Companies facing challenges in inventory management due to a wide variety of parts * Companies aiming to reduce inventory costs 【Benefits of Implementation】 * Reduction in inventory costs * Resolution of excess and shortage of parts * Optimization of storage space

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the logistics industry, optimizing inventory is crucial for achieving efficient transportation. Excess inventory increases storage costs, while insufficient inventory leads to missed opportunities. This video explains how to analyze the current situation by focusing on inventory value and inventory turnover period. By understanding this analysis method, you can identify challenges in inventory management and implement improvements. 【Usage Scenarios】 - Inventory management within warehouses - Improvement of transportation efficiency - Reduction of inventory costs 【Effects of Implementation】 - Visualization of inventory - Reduction of unnecessary inventory - Understanding optimal inventory levels

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, proper inventory management is essential for cost reduction and an efficient production system. Challenges such as inventory amounts not decreasing while necessary products are in short supply can lead to missed opportunities. This video explains how to analyze the current situation using inventory amounts and inventory turnover periods as the basics of inventory management. This video material will be helpful for improving inventory management. 【Usage Scenarios】 * Inventory management departments of electronics manufacturers * Procurement personnel for components * Production management departments 【Effects of Implementation】 * It becomes easier to understand the current state of inventory. * You can identify issues in inventory management. * You can improve inventory turnover rates.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In automotive parts management, proper inventory management is essential. Excess inventory increases storage costs, while insufficient inventory can lead to production line stoppages. This video explains how to analyze the current situation by focusing on inventory value and inventory turnover period. Through this analysis, you can understand the surplus and shortage of parts and achieve efficient inventory management. 【Usage Scenarios】 - Inventory management of automotive parts - Planning for parts procurement - Reducing inventory costs 【Benefits of Implementation】 - Optimization of inventory - Cost reduction - Stabilization of parts supply

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration