1~41 item / All 41 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~41 item / All 41 items

Filter by category

As a pioneer in the roll forming machine manufacturing that supports lightweight automotive design, we realize a turnkey line based on mass production achievements that addresses the unique forming challenges of high-strength steel with complex profile capabilities. Dreistern provides comprehensive production technology that includes metal profile forming lines, forming tools, punching and cutting devices, as well as control and software, with roll forming technology at its core. Beyond supplying standard machines, we achieve optimized roll forming solutions through line configuration, process design, tooling design, and system integration tailored to customer requirements. Our technology is adopted across a wide range of industries, including automotive, construction, electronics, logistics, and furniture, enabling high-precision metal profile production that accommodates diverse cross-sectional shapes and materials. Based on years of accumulated forming know-how and control technology, Dreistern supports stable quality and efficient production. Headquartered in Germany, Dreistern provides technical support and services to customers worldwide through a global network that includes Europe, Asia, and North America.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Due to its simple internal structure, it can be used intuitively and is suitable for mass production. It is possible to connect the electric component for analysis to any computer via USB.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In robots used in manufacturing sites, when calibration/correction of the robot becomes necessary due to parts replacement or collisions during maintenance, using Wiest's LaserLAB allows for automatic, rapid, and high-precision robot calibration/correction while keeping the robot installed on-site. This contributes to reducing downtime of the production line and labor hours due to robot stoppages.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The world of casting is transitioning to a new stage. The rise of next-generation components such as large giga-casts and battery trays presents challenges in manufacturing and inspection processes. VisiConsult has developed the XL version of PRO FI for this purpose. PRO FI Giga is a unique system that can be highly customized to meet customer needs. It offers various loading concepts and advanced automation from vertical to horizontal. This allows the system to be integrated into manufacturing and automation lines. With high-speed manipulators, X-ray inspections can be conducted in accordance with the cycle time of the manufacturing line. As a result, the inspection process does not become a bottleneck compared to inspections in large manual cabinets. The ADR (Automated Defect Recognition) software automatically detects and measures defects, achieving a true automation process.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■Two X-ray sources can be mounted inside the nano-micro focus X-ray tube It is possible to mount two X-ray sources: a 240kV high-resolution transmission nano-focus X-ray tube and a 300kV high-power reflection micro-focus X-ray tube. The ability to choose between two types of X-ray tubes allows for a wide range of sample scanning, from high-resolution imaging of organic materials to imaging of high-density metallic objects that require high power. ■Large 417 mm, 139 μm pixel pitch high-resolution flat panel detector With a resolution of 3K and a size of 417 x 417 mm, the large flat panel detector with a pixel pitch of 139 μm delivers class-leading performance. ■High-precision granite manipulator Equipped with a compact design, the high-precision granite manipulator allows for convenient imaging of various subjects with the best resolution and high accuracy at all times.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ Equipped with a high-output nano-focus X-ray tube with a tube voltage of 240kV and a tube output of 80W, the X-ray tube achieves high-resolution imaging with a transmission type. The high tube voltage of 240kV provides sufficient power for detecting details even in high-density metal objects. It enables scanning of a wide range of samples, from plastics and organic materials to composite materials and lightweight alloys. ■ High-resolution flat panel detector with a large size of 427 mm and a pixel pitch of 100μm. This large flat panel detector, with a resolution of 3K and dimensions of 427 x 427 mm, delivers class-leading performance. ■ High-precision granite manipulator. The compact design features a high-precision granite manipulator, allowing for convenient imaging of various subjects at the highest resolution and accuracy.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

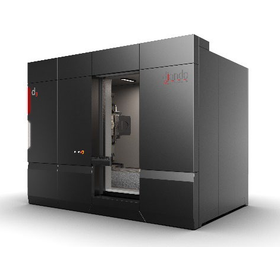

■The diondo d7 linear accelerator CT system is available in 3 MeV, 6 MeV, and 9 MeV [MeV] options. ■It is the most powerful CT system in the diondo Line lineup. ■It is suitable for analyzing high-density materials such as titanium, copper, steel, or thick aluminum, as well as large components like engines, crankcases, stators, and turbine blades. ■The linear accelerator significantly expands the range of CT applications. The output range in MeV allows for the analysis of materials that are difficult to scan. As demonstrated by fuel cells, it provides clearly contrasted voxel models even for challenging combinations of materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ Tube voltage 150kV, tube current 500μA high-output micro-focus X-ray tube The sealed micro-focus X-ray tube requires no maintenance and delivers sufficient power to detect fine details even in high-density metal bodies. It enables scanning of a wide range of samples, from plastics and organic materials to composite materials and lightweight alloys. ■ Large 417 mm high-resolution flat panel detector With a resolution of 3K and a large flat panel detector size of 417 x 417 mm, it delivers class-leading performance. ■ Motor-driven axis Equipped with a compact design and a full-fledged manipulator featuring zoom and height axes, it allows for convenient imaging of various subjects at the highest resolution.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing the features of the ultragrind roll grinding machine from Georg GmbH in Germany. > It is characterized by high precision, high robustness, and excellent after-sales service. > The fixed spindle with a movable spindle base extends the machine's lifespan and allows for safe workpiece loading. > The robust machine bed equipped with a third guideway optimally supports the workpiece during grinding, providing high grinding capacity with optimal precision. > Custom-made machine design. > Excellent wear resistance due to static pressure guides on all axes, minimizing maintenance. > Static pressure grinding spindle. > This machine is suitable for CBN grinding and can accommodate future technologies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The BLOHM JUNG surface grinding machines, boasting the three essential elements of machine tools—"productivity," "operability," and "precision"—have been in operation for many years in various locations around the world, catering to different applications and needs. With over 35,000 machines sold and the accompanying experience, research and development are focused on further enhancing efficiency, from standard machines to customized solutions. The goal of the technical staff is to tirelessly support customers until the machine has completed its tasks, promptly and carefully addressing individual requests for processing tests, training, maintenance, retrofitting, and more. In 2008, BLOHM and JUNG merged to form BLOHM JUNG. The combination of expertise from both brands has elevated the standards of "precision," "quality," and "efficiency" to a new level, while user demands have also diversified and evolved. As a member of the UNITED GRINDING GROUP, BLOHM JUNG has established branches in India, China, Russia, and the United States, built a sales and service network in 40 countries worldwide, and focuses on machine development and manufacturing at its Hamburg facility, with service and technology based in Göttingen, achieving significant results.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The ultra-precision surface and profile grinding machine J600 accommodates a wide range of applications, from single products to small batch production, across various industries. It particularly reflects deep insights into the needs of the tool and mold manufacturing sector. With a modular concept, it provides optimal specifications tailored to user requirements, while the vibration-damping properties of the hydro-dynamic EasySlide guideways and the high acceleration performance and infeed speed of the high-performance recirculating ball screw drive promise high productivity. The user-friendly German-made J600 features double-opening sliding doors for the processing area, as well as a maintenance door, significantly enhancing work efficiency. The EasyMode further improves operability, allowing for semi-automatic and manual grinding using a manual pulse handle.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Visual Die Protection protects molds that are in production operation. This camera-based system detects hazardous situations, such as foreign objects, in real time, allowing the line to stop before the mold closes, completely preventing damage. This minimizes risks and reduces costs. Visual Die Protection is a multifunctional and open system, making it applicable to presses from other manufacturers and other fields. It can be easily retrofitted and has a wide range of applicability, allowing users to utilize this system flexibly. It can be applied not only to transfer presses but also to progressive die lines, hot stamping lines, resin molding, and assembly lines. The system can be used without being limited to molding technology.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

smartPREDICT-AE is a multi-sensor system based on iNDTact's high-bandwidth vibration sensor iMPactXS. It enables the high-sensitivity detection of vibrations emitted by machinery and allows for precise monitoring of operational states and the load conditions affecting the structure. In addition to high-bandwidth operation and high-sensitivity vibration detection capabilities, a micro-electromechanical system (MEMS) measures acceleration and angular velocity, providing additional motion information. The bottom of smartPREDICT-AE is equipped with a temperature sensor alongside the iMPactXS, allowing for the monitoring of internal temperature as a sample value. smartPREDICT-AE can measure parameters and communicate directly with machinery (PLC) and I-IoT edge devices via Modbus RTU.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company handles magnetic property measurement and analysis equipment from Brockhaus in Germany, which can perform high-precision measurements and analyses of motor core magnetic characteristics in compliance with global standards, including JIS. We offer models suitable for full inspection before the assembly of motor laminated cores, as well as models specialized for the analysis of tooth cores and back cores. 【Product Lineup】 ◎ Base Model "BST-M" ■ Supports maximum magnetization of 2 Tesla and maximum frequency of 20 kHz ■ Magnetization methods include B·H control, PWM, or user-defined specifications ■ Ideal for quality control of motor laminated cores ◎ FA Model "BST-FA" ■ Supports maximum frequency of 20 kHz ■ Complies with IEC60404 standards for evaluation ■ Cycle time of 3 to 15 seconds ◎ Analysis-Specialized Model "BST-L" ■ Automatic measurement model equipped with X, Y, Z positioners ■ Supports analysis of motor cores from different manufacturing processes ■ Adjustment accuracy of 0.2% and reproducibility of 0.3% *For more details, please refer to the documentation. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Safety ■ All components comply with international standards for collaborative robots ■ J6 components use colors that emphasize visibility during operation Easy Installation ■ Simple structure that can be intuitively mounted ■ Installation without the need for J6 offset Ease of Use ■ J6 components with sufficient rigidity can be gripped for direct teaching of the robot ■ J6 component mechanism can be easily adjusted even after installation

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For industrial multi-joint robots. Automatically measures and corrects the work reference "tool coordinates" to meet the high precision requirements of robot applications. ■ Target Applications: 1. Cutting processing 2. Deburring 3. Welding (spot, arc) 4. Sealing, etc. ■ Key Features: 1. Tool coordinate measurement input – Automates 3-point/5-point teaching during tool coordinate setting. 2. Automatically corrects tool deformation caused by steady/non-steady operations. 3. Detects the relative position between the robot and the fixture.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose machines and processes optimized for hydraulic stator and rotor grinding. This product is developed specifically for hydraulic stator and rotor grinding, utilizing a dedicated grinding spindle that maintains profile accuracy while achieving high productivity. With a powerful grinding spindle of up to 62KW, a bed made of ductile cast iron providing excellent damping characteristics, and a structure optimized through finite element analysis for high vibration resistance and temperature stability, we achieve high precision and high productivity. It is capable of continuous dress grinding and CBN grinding, and we can offer a package with various parameter monitoring functions compatible with IoT. 【Features】 ■ A structure with high vibration resistance and temperature stability achieves high precision and high productivity ■ Compatible with CBN grinding ■ Can propose a package with various parameter monitoring functions compatible with IoT ■ Achieves high productivity while maintaining profile accuracy *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose machines and processes optimized for flat broach tool grinding. This product features a powerful grinding wheel spindle with a maximum output of 62KW, high damping characteristics due to its ductile cast iron bed, and a structure optimized through finite element analysis that provides excellent vibration resistance and resilience to temperature changes, achieving high precision and high productivity. It is also capable of continuous dress grinding and CBN grinding. We can offer a package with various parameter monitoring functions compatible with IoT. Additionally, interactive software developed specifically for broach tool grinding accommodates a variety of requirements. 【Features】 ■ Powerful grinding wheel spindle with a maximum output of 62KW ■ High damping characteristics from the ductile cast iron bed ■ High vibration resistance optimized through finite element analysis ■ Structure resilient to temperature changes, achieving high precision and high productivity ■ Interactive software that meets diverse requirements *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose machines and processes optimized for punch die grinding. Our product achieves complete processing of punch dies in one clamping due to the grinding wheel arbor capable of mounting multiple grinding wheels and the machine's rigidity. With a powerful grinding spindle of up to 62KW, a bed made of ductile cast iron providing high damping characteristics, and a structure optimized through finite element analysis for excellent vibration resistance and temperature change resilience, we realize high precision and high productivity. It is also capable of continuous dress grinding and CBN grinding, and we can offer a package with various parameter monitoring functions compatible with IoT. 【Features】 ■ High vibration resistance and a structure resilient to temperature changes ■ Achieves high precision and high productivity ■ Capable of continuous dress grinding and CBN grinding ■ Can propose a package with various parameter monitoring functions compatible with IoT ■ Realizes complete processing of punch dies in one clamping *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose machines and processes optimized for grinding screw rolling flat dies. This product features a powerful grinding wheel spindle with a maximum output of 62KW, high damping characteristics due to a ductile cast iron bed, and a structure that is resistant to temperature changes, optimized for high vibration damping characteristics through finite element analysis, achieving high precision and high productivity. It is also capable of continuous dress grinding and CBN grinding. We can offer a package with various parameter monitoring functions compatible with IoT. Additionally, an interactive software developed specifically for screw rolling flat die grinding accommodates a variety of requirements. 【Features】 ■ Powerful grinding wheel spindle with a maximum output of 62KW ■ High damping characteristics due to a ductile cast iron bed ■ High vibration damping characteristics optimized through finite element analysis ■ A structure resistant to temperature changes that achieves high precision and high productivity ■ Capable of continuous dress grinding and CBN grinding *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose machines and processes optimized for steering rack grinding. Our product features a powerful grinding wheel spindle with a maximum output of 62KW, a bed made of ductile cast iron that provides high damping characteristics, and a structure optimized through finite element analysis that offers excellent vibration resistance and resilience to temperature changes, achieving high precision and high productivity. We can package various parameter monitoring functions compatible with IoT, and software developed specifically for steering rack grinding meets diverse requirements. 【Features】 ■ Capable of continuous dress grinding and CBN grinding ■ Can be equipped with a grinding wheel changer ■ Able to accommodate complex grinding requirements ■ Software developed specifically for steering rack grinding meets diverse requirements *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product contributes to improved accuracy and productivity through creep feed grinding, which is suitable for grinding requirements that demand high stock removal. It is also compatible with continuous dress grinding and CBN grinding. The powerful 62KW grinding wheel spindle, high damping characteristics provided by the ductile cast iron bed, and a structure optimized through finite element analysis for high vibration resistance and temperature stability achieve high precision and high productivity. We can propose a package of various parameter monitoring functions compatible with IoT, and since it can also be equipped with a wheel changer, it can accommodate complex grinding requirements. 【Features】 ■ Creep feed grinding contributes to improved accuracy and productivity ■ Can propose a package of various parameter monitoring functions ■ Can be equipped with a wheel changer ■ Capable of accommodating complex grinding requirements *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose machines and processes optimized for chuck nail grinding. This product features a powerful grinding wheel spindle with a maximum output of 62KW, high damping characteristics due to a ductile cast iron bed, and a structure optimized for high vibration resistance and temperature change through finite element analysis, achieving high precision and high productivity. It is also compatible with continuous dress grinding and CBN grinding. We can offer a package with various parameter monitoring functions that support IoT. Additionally, it can be equipped with a grinding wheel changer, allowing it to meet complex grinding requirements. 【Features】 ■ Powerful grinding wheel spindle with a maximum output of 62KW ■ High damping characteristics due to a ductile cast iron bed ■ High vibration resistance optimized through finite element analysis ■ Structure resistant to temperature changes, achieving high precision and high productivity ■ Compatible with continuous dress grinding and CBN grinding *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Dress Pack System" is a protective system designed to prevent disconnections that are likely to occur with external cables of robots, thereby preventing line stoppages and achieving stable operation. It has been registered as a specified product by automotive manufacturers in Europe and North America and has been used for many years. 【Features】 ■ Designed and proposed according to the type and application of the robot ■ Easy to install; can be provided in an assembled state with various parts ■ Supports delivery with cables and connectors installed inside the hose ■ Even if a malfunction occurs, it can be repaired in about an hour using just a hex wrench.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "XRHGantry" is a ceiling-mounted turnkey solution with seven programmable axes. With a wide selection of X-ray sources and detectors, it can address various inspection challenges. The seven independently controllable axes enable this product to handle very difficult conditions. Notably, it features a tilt function that allows for the measurement of elliptical shapes in double-wall welds, as well as controllable magnification that enables dynamic zooming into point areas. VisiConsult is a specialist in custom specifications and standard types of X-ray systems. Our cutting-edge performance and high flexibility provide tailor-made solutions to the problems faced by our customers. 【Features】 ■ Designed for the inspection of complex parts ■ CNC programmable seven-axis drive ■ Customizable design and layout ■ Available for large parts with up to 450kV ■ Installed in a cabinet or X-ray bunker *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "XRH222TL" is conveniently designed for placing inspection items using cranes or forklifts mounted on the ceiling. With ultra-precise axes, it enables a perfect inspection portfolio. This cabinet can be used as an inline or offline system for many applications, including casting, composite materials, welding, and aerospace components. VisiConsult is a specialist in custom specifications and standard types of X-ray systems. Our cutting-edge performance and high flexibility provide tailored solutions to the problems faced by our customers. 【Features】 ■ Inspection items can be placed from the ceiling or door ■ CT - Computer Tomography ■ ADR - Automatic Defect Recognition ■ Compliant with international standards ■ Diverse image archiving including DICONDE *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

VisiConsult is a specialist in custom specifications and standard X-ray systems. Our cutting-edge performance and high flexibility solve the problems faced by our customers with tailor-made systems. In mass production industries such as the automotive sector, 100% X-ray inspection has become a bottleneck in production. The 'XRHRobotStar' is a fully automated inline inspection robot system that enables unparalleled processing speed while meeting all standard industrial and corporate specifications. 【Features】 ■ High scalability through system clusters ■ Automatic Defect Recognition (ADR) functionality ■ Capable of inspecting mixed production ■ Developed for the automotive industry ■ Proven implementation worldwide *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company handles the tailored blank high-speed laser welding system from Andritz Soutec. "SOUSPEED" is one of the representative models, specifically designed for high productivity laser welding of tailored blanks with a focus on linear welding. With a tracking camera, it measures the position and dimensions of the groove online, allowing for high-precision beam position adjustment and variable control of the filler wire supply, achieving uniform bead shape and reducing scrap rates. We also have experience in welding various plate thicknesses and high-tensile materials, and we are open to consultations regarding applications as well as joint development of tailored blanks with various OEM companies. 【SOUSPEED Features】 ■ 40-100% higher productivity compared to existing TWB welding systems ■ Expanded process window for boron steel welding through filler wire gap management ■ Realization of thin sheet material welding through mismatch control ■ Butt joint positioning (without Z-bar) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company handles the "Hot Stamp Roller Hearth Continuous Heating Furnace System" from Schwartz. One of the features that ensures high quality is the numerous parameters that can be individually adjusted. This allows for versatility, enabling rapid and easy adaptation of heat treatment to changing manufacturing needs. Since its establishment in 1984, Schwartz has been building customized heat treatment systems and related processing equipment to meet the unique manufacturing requirements of each customer. To date, over 1,000 heating furnace systems have been delivered to 30 countries. [Features] ■ Various layouts tailored to the installation site, including double-row and two-story heating furnaces ■ Selectable furnace atmospheres (air, protective gas) ■ Dew point management function through dry air supply ■ Compatibility with various plated and non-plated materials ■ Partial softening using a uniquely developed inline heat distribution station ■ Gas furnace, electric furnace, or hybrid type *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"ZeroTouch Multi" is a multipurpose measurement platform that combines multiple sensor technologies equipped with innovative multi-spectral light and deep learning software within a single installation area. This inspection machine, designed for robust industrial use, provides accuracy, precision, and speed that optimize inspection time under the manufacturing environments required by manufacturers. DWFritz Metrology leverages over 40 years of experience in developing high-precision automated measurement solutions to deliver next-generation high-speed, non-contact measurement products. 【Features】 ■ Simultaneous capture of multiple measurements in an overwhelmingly shorter time compared to conventional three-dimensional measuring machines ■ Easy creation of inspection plans for parts, reducing measurement time for different components ■ Non-contact shape measurement with micron-level precision and high reproducibility ■ Reduced setup time for each part due to easy part exchange ■ Improved reproducibility through on-site calibration *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"ZeroTouch Gear" is a non-contact gear inspection device that creates three-dimensional point clouds. It enables three-dimensional inspection of complex-shaped parts using multiple sensors, providing manufacturers with real-time measurement and inspection data to optimize manufacturing processes and improve ROI. DWFritz Metrology has leveraged over 40 years of experience in developing high-precision automated measurement solutions to introduce a next-generation lineup of high-speed, non-contact measurement products. 【Features】 ■ Inspection times that are significantly faster compared to conventional gear measurement techniques ■ Complete inspection of gears and tooth shapes with measurement cycle times starting from 30 seconds per part ■ Prevention of defective gears from flowing into the final assembly process ■ Simple interface with manufacturing processes integrated with robots for loading and unloading ■ Three-dimensional inspection of complex shapes using multiple sensors *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Blockhaus Corporation is recognized as a global market leader in high-quality, high-performance magnetic measurement and analysis instruments. The company's measuring instruments, compliant with IEC60404, are widely adopted in research institutions and manufacturing sites around the world for research and quality control purposes. They meet diverse needs related to soft magnetic materials, from offline and automatic inline measurements to Epstein and SST testing machines. 【Measurement Systems (Excerpt)】 ■ Electromagnetic Property Measurement Device C510 ■ Electromagnetic Property Measurement Unit MPG 100/200 D ■ Stacking Factor Testing Machine SFT 300 ■ Franklin Tester FT 600 ■ Inline Measurement System EBA/TGD *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Block House Inc. is recognized as a global market leader in high-quality and high-performance magnetic material measurement and analysis instruments. The company's measuring instruments, compliant with IEC60404, are widely adopted in research institutions and companies around the world for quality control and research purposes. With measurement systems such as the "Histogram HG200" and "Fluxmeter F10," it is possible to perform various measurements including hysteresis curves, measurement temperature, and magnetic moment predictions. 【Measurement Systems (Excerpt)】 ■ Histogram HG200 ■ Fluxmeter F10 ■ Gaussmeters BGM101 & 201 ■ XYZ Scanner & Rotor Tester ■ Electromagnet System *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "PROFIMAT XT" is a high-precision profile grinding machine suitable for grinding requirements that demand high removal rates. With a powerful grinding spindle output of up to 62 kW, a bed made of ductile cast iron providing high damping characteristics, and a structure optimized through finite element analysis that offers excellent vibration resistance and temperature stability, it achieves high precision and high productivity. It is capable of continuous dressing grinding and CBN grinding. Various parameter monitoring functions compatible with IoT can be offered as a package. It can also be equipped with a wheel changer, allowing it to meet complex grinding requirements. 【Features】 ■ Five sizes available (408/412/608/612/620) ■ Grinding spindle drive of up to 62 kW ■ Integration of four technologies *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

ANDRITZ Kaiser provides custom-made solutions for various applications, covering the entire production line from single presses to "conveyor systems," "automation," "tooling," and "workpiece handling devices." The company offers both conventional presses and servo presses, with all machines manufactured using a tie rod structure. The machine frames can be supplied in a complete cast iron version with a maximum pressing force of 10,000 kN. Combined with a proven linear guide system, KAISER presses achieve excellent precision and rigidity. In particular, the company holds a global market share for press lines that accommodate rotor/stator segments for large motors with a diameter of over 600mm and a length of over 1000mm. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Rotary Swaging Machine" is a process that boasts a wide variety of moldable shapes and different degrees of formation. By enhancing hardness and tensile strength without cutting the flow lines, the strength and stability of the workpiece are improved. Compared to other cold forging processes, it can be applied to a wide range of applications. 【Features】 ■ Lightweight design for hollow components ■ Shorter cycle time compared to machining ■ High strength ■ High precision ■ Resource-saving production without cutting *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Axial Forming Machine" is a technology that can be utilized in various fields for processing components equipped with high-precision splines. We guarantee ultimate precision for all splines. Since the teeth are forged exactly as per the tool, pitch errors do not occur. With extremely accurate profiles and absolutely symmetrical fillet radii, fatigue strength is significantly improved. 【Features】 ■ Lightweight ■ Fast ■ High strength ■ High precision *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "XRHCount" is a non-contact automatic SMD counter. All that is required from the operator is to set the reel in the drawer and press a button once. Regular support from engineers is not necessary, and it is maintenance-free. Thanks to this simplicity, operators can be trained in just a few minutes. 【Features】 ■ Reduces counting costs by 95% ■ Global component database ■ Integrated with warehouse systems ■ Less than 10 seconds per reel ■ Supports Industry 4.0 and traceability ■ Zero programming effort *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The idea of the technology of Compositence began with the lack of techniques for arranging fibers according to specific load paths. Dry fibers, thermosetting resins, thermoplastics—any material can be processed with patented technology. The lightweight production of composite materials and composite parts is a daily driving force, and the engineering team has been working on composite materials for over 25 years. Iris Co., Ltd. is the exclusive distributor of Compositence in Japan. 【Features】 ■ Adjusted stacks and blanks ■ Engineering ■ Manufacturing facilities ■ After-sales service *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"PRIMOS CR" is an ideal optical 3D measurement system for skin, combining high operability and high-resolution sensors with new 3D imaging software for capturing and evaluating before-and-after images. It enables quantification of the depth and volume measurement of the skin's fine structure. Additionally, it measures local features in detail, such as fine lines, wrinkles, crow's feet, skin texture, and scars, using high-resolution images. [Features] ■ Quantification of the depth and volume measurement of the skin's fine structure ■ High-resolution images ■ Newly equipped VECTRA 3D software ■ Instant confirmation of thumbnail images *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are currently offering a technical document explaining "BSW Vibration and Sound Insulation Technology" from Iris Co., Ltd., your project partner as an industrial user and consumer. The document includes application examples of vibration isolation and impact sound insulation under high loads, as well as detailed information on Regufoam vibration and Regupol vibration technologies. [Contents (excerpt)] ■ Company information about BSW ■ Application examples of vibration isolation and impact sound insulation under high loads ■ Overview and details of Regufoam vibration technology ■ Overview and details of Regupol vibration technology ■ Details of floating floor impact insulation technology *For more information, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration