1~45 item / All 71 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 71 items

Filter by category

In the beverage industry, ensuring traceability in the manufacturing process is crucial for maintaining product quality and safety. In particular, the work of attaching and detaching pipes during the filling process increases the risk of foreign substance contamination and may compromise the accuracy of traceability. Quitto has been developed to address these challenges and enhance traceability. 【Usage Scenarios】 - Raw material acceptance and supply lines - Cleaning processes 【Benefits of Implementation】 - Reduction in work time - Traceability improvement

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the food industry, maintaining food quality and establishing an efficient production system are essential. In particular, the process of attaching and detaching piping during manufacturing can increase work time and the risk of foreign object contamination. The attachment and detachment of hose clamps takes time and carries the risk of dropping seals or causing injuries. Quitto has been developed to address these challenges. 【Usage Scenarios】 - Filling process for inner care products - Raw material receiving and supply lines - Cleaning processes 【Benefits of Implementation】 - Reduction in work time - Decrease in the risk of foreign object contamination - Alleviation of worker burden

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the frozen food industry, post-use pipe cleaning is crucial for maintaining product quality. It is particularly important to maintain a hygienic environment from the acceptance of raw materials to the filling of products on the manufacturing line. The process of attaching and detaching pipes can increase work time and the risk of foreign matter contamination. Quitto was developed to address these challenges. 【Usage Scenarios】 - Filling process for inner care products - Raw material acceptance and supply lines - Cleaning processes 【Benefits of Implementation】 - Reduction in work time - Decrease in the risk of foreign matter contamination - Alleviation of worker burden

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the beverage industry, ensuring traceability in the manufacturing process is crucial for maintaining product quality and safety. Accurate records and management are required at each stage, from the acceptance of raw materials to the shipment of products. In particular, the work of attaching and detaching pipes during the filling process increases the risk of foreign matter contamination and may compromise the accuracy of traceability. Quitto has been developed to address these challenges and enhance traceability. 【Usage Scenarios】 - Acceptance and supply lines of raw materials - Cleaning processes 【Benefits of Implementation】 - Reduction of foreign matter contamination risk - Shortening of work time - Improvement of traceability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the baking industry, hygiene management during the manufacturing process is crucial for maintaining product quality. In particular, it is necessary to minimize the risk of foreign matter contamination at the piping connections from the acceptance of raw materials to the packaging of products. Traditional hose clamps take time to attach and detach, and issues with falling gaskets and cleanliness have posed challenges for quality management. Quitto was developed to address these issues. 【Usage Scenarios】 - Filling process for inner care products - Raw material acceptance and supply lines - Cleaning processes 【Benefits of Implementation】 - Reduction in work time - Decrease in the risk of foreign matter contamination - Alleviation of worker burden

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the production of seasoning manufacturer products, hygiene management and an efficient production system are required. In particular, the work of attaching and detaching pipes during the filling process can increase work time and heighten the risk of foreign matter contamination. The attachment and detachment of the sanitary clamp takes time and carries the risk of dropping gaskets or causing injuries. Quitto was developed to address these challenges. 【Usage Scenarios】 - Filling process for inner care products - Raw material receiving and supply lines - Cleaning process 【Benefits of Implementation】 - Reduction in work time - Decrease in the risk of foreign matter contamination - Alleviation of worker burden

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the confectionery industry, there is a demand for diversification of recipes and improvement of manufacturing efficiency. In particular, the rapid switching of materials and the maintenance of a hygienic environment are crucial. The assembly and disassembly of piping in the filling process can increase work time and heighten the risk of foreign matter contamination. Quitto has been developed to address these challenges. 【Usage Scenarios】 - Filling process for inner care products - Raw material receiving and supply lines - Cleaning processes 【Benefits of Implementation】 - Reduction of work time - Decrease in the risk of foreign matter contamination - Alleviation of worker burden

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Excellent features that can meet diverse needs: 1) Installation dimensions can be customized to meet customer requirements, making it easy to add to existing equipment. 2) A unique mechanism that alleviates vibrations and shocks maintains a stable connection over long periods. 3) The proprietary connector connection method eliminates concerns about contact failure, enabling safe and efficient charging even at high currents. 4) The unique waterproof structure allows for use in outdoor environments. 5) A design that requires no maintenance for an extended period reduces operational costs and enhances reliability.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In food manufacturing, hygiene management and an efficient production system are required. In particular, the process of attaching and detaching pipes during the filling process can increase work time and the risk of foreign object contamination. The attachment and detachment of the hose clamp takes time and also carries the risk of dropping gaskets or causing injuries. Quitto was developed to address these challenges. 【Usage Scenarios】 - Filling process for inner care products - Raw material receiving and supply lines - Cleaning process 【Benefits of Implementation】 - Reduction in work time - Decrease in the risk of foreign object contamination - Alleviation of worker burden

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We digitize and datafy sound, making the condition of rotating machinery and other equipment "visible." This allows for easy condition diagnosis through sound, achieving equipment diagnostics that do not rely on experience. This product is a device condition diagnosis tool that anyone can use via a smartphone or PC app. It can directly capture the sound of the target equipment without being affected by surrounding noise. The captured sound data is visualized in graphs, enabling "visibility" of sound without relying on the knowledge or experience of the operator. It allows for the sharing of sound data, which was not possible before. Thresholds for abnormal sound inspections, which varied from person to person, can be qualitatively defined by graphing the sound.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Quitto has been adopted at a food manufacturing factory. The hose connection between the tank and the filling machine required the removal and attachment of the hose clamp every time the filling material was changed in order to clean the hose. Traditionally, this removal and attachment process of the hose clamp took about 20 seconds to 1 minute. Additionally, when reattaching it to the piping after cleaning, there were instances where the gasket would fall to the floor, necessitating another cleaning, leading to time loss during setup changes and piping cleaning. Our Quitto can be easily attached and detached with one hand by anyone. Its unique structure allows for the attachment of a large gasket while pressing it in place, completing the attachment and detachment process in just a few seconds. Since the gasket is securely fixed to the piping, the risk of dropping it on the floor during attachment is almost eliminated. By using it at existing hose clamp connection points where frequent attachment and detachment occur (such as at the end of hoses), it contributes to increased productivity and safety. We also have demo units available, so please feel free to reach out if you're interested. This product is a new development in collaboration with PACRAFT, a packaging machine manufacturer (part of the same Nabtesco group as us). *Patent, trademark, and design applications have been filed.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have introduced an automatic filling machine in a factory that handles OEM for cosmetics. Previously, when cleaning hoses, the process involved attaching and detaching with a heel clamp, which particularly for those who are not skilled, posed several issues: - It took a long time to attach and detach. - It was not securely clamped, leading to leaks. - Gaskets were dropped on the floor during installation. - There were risks of cuts and other injuries. These tasks were cumbersome and the fear of injury sometimes led to part-time workers leaving their jobs. Since this factory is located in a rural area, they also struggled to hire replacement staff. The new product, Quitto, allows anyone to easily attach and detach with one hand! *This new product was co-developed with PACRAFT and is currently under patent and trademark application. With its unique structure, it presses a large gasket while being installed, completing the attachment and detachment process in just a few seconds. Additionally, since the gasket is securely fixed to the piping, the risk of dropping the gasket on the floor during installation is almost eliminated. By using it in existing heel clamp connection points, especially in areas with frequent attachment and detachment (such as the end of hoses), it contributes to increased productivity and safety.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

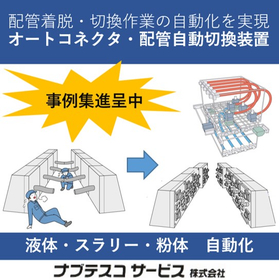

Our company designs and manufactures "Auto Connectors (automatic attachment and detachment devices)," "Auto Couplers," and "automatic piping switching devices" to automate the attachment and detachment of piping and electrical wiring for liquids, slurries, and powders. We contribute to the automation of factories, increased productivity, and improved safety for workers. Regardless of whether it is fluids or powders, we offer custom design and manufacturing from individual couplers to entire systems based on customer requirements. ■ Case Study Collection Available We provide a "case study collection" summarizing examples from the following industries: chemicals, pharmaceuticals, daily necessities, food, beverages, automotive, industrial machinery, and steelmaking. ■ New Product Launch (Patent Pending) A new case for "Quitto," which will be launched at the end of 2024, has been added. This groundbreaking new product can shorten the attachment and detachment time of the helical clamp to just a few seconds. It can be done easily by anyone with one hand. The risk of dropping the gasket during connection is also minimized. We encourage you to try it out. *For more details, please refer to the PDF materials or feel free to contact us. *Demo units and cut models of the products are also available.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- Assembly work is performed on the upper side, while product removal and installation are carried out on the lower side, increasing the equipment's operating rate. - An auto connector is used for air supply to the jig, allowing for automatic connection and disconnection during the jig's rotation. - The equipment becomes more compact compared to using rotary joints or cable carriers. - Additionally, the auto connector enables a rotating system, which contributes to cost reduction and maintenance efficiency.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The mold automatic exchange device automates the installation and removal of necessary utility wiring and piping inside the mold, reducing setup changeover time. It also reduces defective products caused by connection errors and improves work safety. The fluid joints (couplers and connectors) have a non-spill structure, which minimizes fluid leakage to the outside, keeping the floor clean.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

During the mold exchange of the vulcanizing machine, it was necessary to detach and attach the heating medium oil and steam piping, which posed a risk of burns to workers due to the high temperatures of the piping. Additionally, it was necessary to wait for the piping temperature to drop, resulting in poor production efficiency, including the piping attachment and detachment work. We developed a special heat-resistant connector capable of withstanding high temperatures (heat resistance up to 250°C / proven track record). Furthermore, since the molds of vulcanizing machines are often thin, there is limited space to install auto connectors. By leveraging our custom-made strengths, we devised shapes that flexibly fit the customer's equipment, solving the space issue and achieving automation of the attachment and detachment work. This improved worker safety and increased production efficiency.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a wireless power supply and charging system that can be installed on AGVs, AMRs, drones, service robots, etc. ◎ Compact and lightweight (150W, 330g and up) ◎ Strong against positional deviation (0-50mm) ◎ Dustproof and waterproof (IP67) ◎ User-friendly interface and fleet management ◎ Compatible with various batteries (LiPO, LiIon, LiFePO4, NiMH, NiCAD, etc.) ◎ Uses a frequency of 6.78MHz ◎ Compatibility between transmitter and receiver <Product Lineup> ■ Transmitter (Power Transmission Unit) TR-302 (300W) TR-302 Edge (IP54 compliant) ■ Onboard Charger (Power Receiving Unit) OC-150 (10A, 150W) OC-251 (12A, 250W) OC-262-ST (12A, 300W) OC-262-WP (IP67 compliant) (12A, 300W) OC-301 (30A, 300W) ■ Power Transmission and Reception Antennas TC-200 RC-100 RC-100-WP (IP67 compliant) * A 1000W type is also under development. ★ Free product rentals are currently available! Please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a device that automates the connection work of pipes and hoses in powder and slurry lines. It enables automatic feeding and dispensing from tanks and containers. We provide custom solutions tailored to each customer's equipment, from individual connectors (couplers) to complete systems including operation panels and control panels. It can be implemented for liquids and various solvents, as well as powders, pellets, slurries, and strong acid lines. It can also be equipped with bridge removal and cleaning functions. It is adopted across a wide range of industries, including material and material manufacturers, semiconductor manufacturers, battery manufacturers, automotive manufacturers, steel manufacturers, and chemical, food, and beverage manufacturers, and can be used in explosion-proof environments. Additionally, we have numerous achievements in lines for hydraulic and pneumatic systems, various gases, liquids, various solvents, food, beverages, alcoholic beverages, and electricity.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a new product developed in collaboration with PACRAFT (part of the same Nabtesco Group as our company). *Patent and trademark applications have been filed. Traditionally, the process of attaching and detaching the Heller clamp took about 20 seconds to 1 minute. Additionally, when attaching it to the piping after cleaning, there were instances where the gasket would fall to the floor, necessitating re-cleaning, leading to time loss during setup changes and piping cleaning. Our Quitto allows anyone to easily attach and detach with one hand. With its unique structure, it presses a large gasket while being attached, completing the process in just a few seconds. The gasket is securely fixed to the piping, significantly reducing the risk of dropping it on the floor during attachment. By using it in existing Heller clamp connection points where frequent attachment and detachment occurs (such as at the end of hoses), it contributes to increased productivity and safety. We also have demo units available, so please feel free to reach out if you're interested.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a device that automates the task of connecting piping (flanges) to tanks or containers that move automatically and manually opening and closing valves with a manual handle. It automatically rotates the manual handle to open and close the valve. If there are concerns about bridging with powders, a bridge removal device can also be added. The structure is designed to prevent vibrations from knockers or vibrators from being transmitted to the device, thus preventing damage from vibrations. We can accommodate customer requests, such as changing the inner surface of pipes and hoses to PTFE. The entire system, including the control panel, drive, and other components, will be custom-designed and manufactured.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In battery manufacturing lines, such as mixing processes, battery material production processes, and semiconductor material production processes, there are tasks that involve loading powders or slurries into tanks or containers and connecting pipes for discharge. By introducing automatic connection devices (auto connectors, auto couplers, auto joints), these tasks can be automated. We have a proven track record with ultra-fine powders like silica and larger powders such as pellets. Additionally, we have experience with high-viscosity slurries. For connectors not available in our lineup, we can design and manufacture them custom-made to meet customer specifications. We can also propose connectors equipped with various functions (joints, piping). Not only individual connectors, but we can design and manufacture complete automatic connection devices (auto connectors, auto couplers, auto joints) that include control panels, control systems, and drives. Automatic cleaning functions, position misalignment correction mechanisms, and locking mechanisms can also be incorporated. Please feel free to consult us first.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose total coordination of automation lines utilizing robots unique to FA equipment manufacturers. This combination of robots and this transport line... This task is for the robot, this task is for the FA equipment... Is it really necessary to use a robot at all... Without being limited to robots, we propose the optimal solution tailored to the customer's equipment and requirements.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a summary page for the RVP series catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Automatically feeds powder, slurry, or liquid into containers moving on conveyors, AGVs, AMRs, forklifts, etc., and also discharges them. Of course, it can also accommodate tanks and flexible containers. We design and manufacture not only the connector part but the entire attachment device as a custom solution. We can also support automatic feeding and discharging of metal powders. Installation in explosion-proof plants and making contact parts chlorine-free and compatible with PTFE is also possible. We will design from scratch according to the user's application. Automatic feeding of powder Automatic discharging and discharge of powder Want to automate the feeding and discharging of raw materials And more Please consult us first.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using auto connectors (auto couplers, auto joints) leads to: - Increased productivity... Automation and reduced setup time enhance production efficiency. - Realization of FMS... Remote operation becomes possible. - Improved safety... There is no need to approach dangerous areas. - Improved safety 2... Automation of switching piping lines for hazardous materials (such as hot water and hydrochloric acid) enhances worker safety by eliminating dangerous tasks. - Environmental improvement... Work in high-temperature, high-humidity, or dirty areas is eliminated. - Enhanced reliability... Prevents incomplete connections and human errors. - Energy savings... There is almost no external leakage during connection and disconnection. - Factory cleanliness... Hoses and wires do not get tangled, and floors are not contaminated with oil or water. Nabtesco Service has accumulated over 50 years of know-how in automatic connection and disconnection (piping and wiring). We have addressed issues such as misalignment during connection, response to reaction forces, handling of special liquids and powders, automation of production lines where metal (ions) leaching is undesirable, and automatic connection and disconnection of high currents. We have confidently provided custom solutions for special environments! If you have any concerns about automation, please feel free to consult us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Automatic Pipe Switching Device" is a system that allows for automatic switching of pipes (hoses) regardless of pipe size or number by driving an integrated mobile unit equipped with an automatic detachable connector in the X and Y directions. By switching from conventional automatic valves or valve blocks, it eliminates concerns about cross-contamination due to internal leaks, contributing to cost reduction and minimizing product loss. We offer custom-made solutions from connectors to devices, providing products tailored to needs such as explosion-proof specifications and outdoor use. 【Features】 ■ Proven track record in manufacturing processes involving high-viscosity materials, powders, and chemical liquids. ■ No worries about product loss due to incorrect connections. ■ Reduces the need for regular maintenance for preventive care. ■ Contributes to the reduction of cleaning water usage and product loss (SDGs). ■ Enhances production efficiency, automation, factory automation, and unmanned operations. ■ No risk of cross-contamination. *For more details, please refer to the materials. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By driving a unit equipped with an automatic attachment/detachment connector (coupler) in the X and Y directions, it connects to any piping. - Physically disconnecting the piping allows for connections at necessary points, eliminating cross-contamination due to internal leaks. - Since there is no concern about cross-contamination, preventive maintenance like that required for automatic valves or valve blocks is unnecessary, leading to reduced running costs. - The ability to connect/switch in a single stroke reduces product loss, cleaning solutions, and waste liquids, contributing to the SDGs! - Compared to automatic valves and valve blocks, production constraints are eliminated. - A pigging system can also be installed, making it suitable for high-viscosity liquid systems, along with an inline flow meter for metering and dosing equipment! - There is a wealth of experience in switching processes for powders, hydrochloric acid, high-viscosity liquids, chemicals, and more!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will design and manufacture everything from connectors to devices tailored to your needs! ■ Benefits of Implementation ◎ Increased work efficiency compared to manual connections! ◎ Eliminates the need for attachment and detachment work in explosion-proof areas, as well as dangerous materials like high-temperature water and hydrochloric acid, freeing workers from hazardous tasks! ◎ Allows for seamless switching compared to automatic valves and valve units, reducing waste liquids, food loss, and cleaning solutions, contributing to SDGs! ◎ No cross-contamination! ◎ Space-saving! ◎ Compared to automatic valves and valve units, there is no need for preventive maintenance of seals, reducing running costs! ◎ Pigging systems can also be incorporated!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

With precise positioning control driven by a stepping motor, you can automatically switch connections by simply specifying the connection joint Bn on the control panel and pressing the execute button. This is optimal for switching one system to multiple lines. It can be manufactured at a lower cost compared to multi-type and straight-type options. - Lubricating oil manufacturing process - Fine chemical process - Alcohol manufacturing process - Food manufacturing process - Beverage manufacturing process - Pharmaceutical raw material input process - Pharmaceutical synthesis process - Semiconductor manufacturing process - Toothpaste manufacturing process - Others

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a steam connector compatible with high-temperature (200℃) steam. The connector itself has a core misalignment tolerance radius of 1.5mm, making installation easy. Of course, we can also design and manufacture the entire automation system.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a resin automatic disconnect valve (connector) that can be used in industries such as chemicals, pharmaceuticals, and food, with no metal leaching whatsoever. The internal valve is made of a single molded PTFE, and the sliding parts during the opening and closing of the internal valve are isolated from the wetted area, preventing product contamination. It is ideal for lines after sterilization and disinfection processes where maintaining a sterile condition is crucial. Additionally, since the valve body and nozzle are made of PVC, there are no metals in the wetted parts, eliminating the leaching of metal ions into the process fluids. It can be introduced into equipment targeting strong acid lines, wafer cleaning solutions used in the semiconductor industry, and chemical agents such as substrate coatings. If you have specific size requirements or special specifications, please contact us as we can design, test, and manufacture custom solutions. Moreover, we design and manufacture not only the valves themselves but also the entire system, including automatic disconnect devices, automatic piping switching devices, and peripheral equipment. If you are facing challenges with automation, please feel free to reach out to us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■What is an Aseptic Connector? It is a valve (coupler/connector) that is optimal for lines following sterilization and disinfection processes where maintaining an aseptic (sterile) state is crucial. The internal valve is molded as a single piece (PTFE), completely isolating the sliding parts from the outside air to prevent product contamination. By adopting a unique "double diaphragm" in the internal valve, it is a revolutionary connector that prevents any liquid pooling inside under any conditions. It is ideal for food and pharmaceutical manufacturing processes. 【Benefits】 High cleanability ⇒ The internal structure is very simple, with no areas for fluid retention. No local SIP required for the shaft ⇒ The internal valve opening and closing mechanism is completely isolated from the fluid contact area. Elimination of contamination ⇒ A unique fixation method has been adopted that prevents bypassing around sealing components. Fail-safe design ⇒ It features a self-locking mechanism during connector coupling. Excellent maintainability ⇒ Compared to conventional valves of the same size, it has achieved miniaturization and lightweight design.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We use an automatic connection and disconnection device (auto connector, auto coupler, auto joint) to automate the connection work of pipes and hoses for feeding materials (raw materials) into the conical dryer (filter dryer) and draining hot water. It is equipped with a mechanism that follows the core misalignment and angles due to stop position accuracy for connection and disconnection. It also has a mechanism (patented technology) that automatically connects and disconnects while following rotating bodies. This can be used not only for the conical dryer but also for automating the work of feeding and discharging materials (raw materials) into tanks. By using our patented automatic piping switching device, the switching work of hoses and pipes for materials (raw materials) into tanks can also be automated. We will design and manufacture customized solutions tailored to your equipment situation, so please consult with us first. We have a proven track record not only with hot water and liquids but also with powders, pellets, silica, and slurries. This leads to improved production efficiency and the elimination of dangerous tasks.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a device that automatically attaches and detaches wiring and connectors such as optical fibers, electrical connections, hydraulic lines, and air hoses for wind tunnel testing equipment. - The utilities to be attached and detached (wiring, connectors, hoses, etc.) will be custom-made according to the customer's requirements. - It is equipped with a mechanism that allows for alignment even with significant positional deviations. The amount of positional deviation that can be accommodated will also be customized for each customer. - Manual attachment and detachment work is no longer necessary, improving testing efficiency. - Automation of the optical fiber connection work is also possible. If there are other utilities that require attachment and detachment, we can custom-make connectors accordingly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In an electronic materials manufacturing factory, we have automated the process of adding cleaning solution to substrates between the raw material line and the transfer tank, as well as from the transfer tank to the filling machine. We developed an automatic detachable connector with all contact parts made of PTFE, eliminating the leaching of metal ions to zero. Additionally, the internal valve is molded integrally with PTFE, providing very high cleanliness. *The body can also be made of PVC. This system is used not only in the semiconductor industry but also in strong acid (hydrochloric acid) lines in the pharmaceutical industry for automatic piping switching devices.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Auto Connector Hydraulic, Pneumatic, and Lubrication Unit" manufactured by Nabtesco Service. The "Auto Connector" features a unique design that minimizes external leakage during connection, ensures a large effective flow cross-section, and achieves low pressure loss. It also has a high tolerance for misalignment during standalone connections. Additionally, the "Hydraulic, Pneumatic, and Lubrication Unit" has a diverse track record of deliveries across a wide range of fields, from government agencies to private companies, both domestically and internationally. **Features of Nabtesco Service's Auto Connector:** - The connection surface has a flat-touch design that minimizes external leakage during attachment and detachment. - It has a high tolerance for misalignment during standalone connections, making installation and adjustment easy. - The durability for automatic attachment and detachment is 100,000 cycles, indicating a long lifespan (based on internal test data). - It meets all needs from single items to units to systems, regardless of fluids, gases, or electricity (custom solutions available). *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have automated the switching operation of hoses (piping) in the blending process for wax manufacturing. We have produced an automatic piping switching device (straight type) for 9 upstream systems and 2 downstream systems. 【Benefits of Implementation】 ■ Automation leads to reduced labor hours and improved production efficiency. ■ Damage caused by connection errors, which occurred every year, has decreased from an annual average of 4 million yen to 0 yen. ■ Burns to workers from steam and hot water during connection and disconnection tasks have been eliminated, removing hazardous work. ■ Continuous cleaning has become possible, significantly reducing the annual water usage for cleaning.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■Before Implementation When changing molds, it took a long time to connect the piping. Additionally, connecting high-temperature hydraulic oil (thermal medium oil) involved dangerous work, leading to risks such as burns for the workers. A few times a year, connection mistakes and incomplete connections also occurred. ■After Implementation We introduced our automatic attachment and detachment device (auto connector, auto coupler, auto joint). It became possible to automatically attach and detach the necessary piping and wiring all at once, improving production efficiency. The dangerous work associated with connecting high-temperature hydraulic oil (thermal medium oil) has been eliminated, enhancing safety. Furthermore, connection mistakes and incomplete connections have been eradicated, achieving the elimination of human error and contributing to improved quality.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The electric connector will automatically attach and detach to the EV charging pallet in multi-story parking lots and similar locations. It can accommodate connections in both horizontal and vertical directions. Additionally, installation outdoors is not an issue. We will design and manufacture custom solutions based on the customer's equipment situation. We can also develop products individually for multi-story parking lot manufacturers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Before Implementation】 When configuring piping using double seat valves, it was not possible to create a seamless pigging system from upstream to downstream. Additionally, due to the piping configuration, product accumulation occurred, resulting in increased usage of cleaning solution and longer cleaning times. 【After Implementation】 We replaced the double seat valves with our automatic piping switching device. By using a full-bore connector without an internal valve, we enabled automatic switching of the piping itself, allowing for both pig cleaning and continuous cleaning, which improved yield and achieved contamination-free results.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Before Implementation】 During paint changes in the painting process, a large amount of cleaning solution was consumed, and the line cleaning time was lengthy. Additionally, in cases where strong acids were used, the durability of the connectors was reduced. 【After Implementation】 We introduced an automatic piping switching device, automating the switching of hoses and pipes. By incorporating our unique high-cleaning connector (patented technology), we were able to reduce the amount of cleaning solution used and shorten the cleaning time. Furthermore, by making all parts of the connector that come into contact with the liquid PTFE, we improved the durability performance in strong acid lines.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have developed a full-bore connector to accommodate the PIG cleaning system. It features our unique locking mechanism, eliminating concerns about lot-out during fluid passage. By automating the piping switching process, we have achieved improved production efficiency and eradicated human error.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have achieved the automation of piping switching for raw material supply and inter-tank transfer. In pharmaceutical companies, switching hoses and pipes was necessary every time there was a recipe change, which posed challenges to production time. There was also a risk of lot errors due to human mistakes. By automating the piping switching, dangerous tasks in explosive environments have been eliminated, allowing recipe changes to be implemented instantly. Additionally, human errors have been eradicated.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Before Implementation】 In the cleaning process of the sterile line, the cleaning solution was circulated for long periods and in large quantities, or the disassembly/cleaning process of the piping took a considerable amount of time. When the piping switch operation was done manually, it took even more time. 【After Implementation】 Equipped with our unique high-cleaning-capable connector (patented technology), we eliminated contamination risks. Additionally, there is no risk of cross-contamination since the piping itself is switched. We significantly reduced cleaning time and the amount of cleaning solution used. This led to a reduction in piping switch time and improved production efficiency.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■Before Implementation The rotation of the jigs used rotary joints and cable carriers, which took up space. Additionally, assembly work and installation/removal tasks could not be performed simultaneously. ■After Implementation By introducing automatic connection devices (auto connectors, auto couplers, auto joints), assembly work can be done on the upper side while product installation and removal can be performed on the lower side, resulting in improved equipment operating rates. The equipment became more compact compared to using rotary joints and cable carriers. A rotation system was made possible, leading to cost reduction and lower maintenance costs.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration