1~27 item / All 27 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

1~27 item / All 27 items

In fact, coffee beans can be plated. However, "plating on coffee beans" requires advanced technology. This time, using our company's know-how, we removed the oil within the porous structure of the coffee beans and properly performed immersion, cleaning, and liquid exchange in the treatment solution, resulting in the completion of "metal coffee beans" without any swelling or stains. Now, while it is certainly not possible to brew coffee with "metal coffee beans," the plating film is metallic, so it has conductivity. So, does it really have conductivity? Can it be used as a switch? We conducted an experiment to see if we could light a small bulb with it. Please refer to the related link for the experimental results. *For more details on the column, please refer to the related link. For further inquiries, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This article explains the principle by which stainless steel develops a black color due to an oxide film. Additionally, it introduces the benefits and functionalities of the oxide film on stainless steel, as well as our plating technology. If you want to enhance features such as anti-glare and reflection suppression, we recommend our black plating "SugoKuro." [Contents (excerpt)] ■ The principle of stainless steel turning black due to an oxide film ■ Functions obtained from black oxide film (black dyeing) ■ Advantages and disadvantages of black oxide film ■ How to blacken stainless steel without an oxide film ■ Black painting ■ Black plating film *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The heat sink's heat dissipation effect varies depending on its surface area. In this column, we will introduce what size of surface area is preferable, as well as the mechanism and necessity of heat dissipation in heat sinks. Additionally, in the latter part of the column, we will present our original technology that enhances cooling effects without changing the base material. For more details, please refer to the related links. [Content Overview (Excerpt)] ■ What is the ideal surface area for heat sinks? ■ Comparison of heat sink shapes and thermal resistance ■ The necessity of heat sinks and the mechanism of heat dissipation ■ Key points for optimizing heat sink design ■ Enhancing heat dissipation effects compactly without increasing surface area *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Do you know what color electroless nickel plating is? The color of the plating applied to the surface for decorative purposes greatly influences the product's visual appeal, so in some cases, the color is considered important depending on what is being plated. This time, our company will explain the characteristics of electroless nickel plating, how to distinguish its color from other platings, discoloration, and more. Please refer to this as a re-confirmation during processing or manufacturing. [Contents (Excerpt)] - Introduction to the color of electroless nickel plating - About electroless nickel plating - Plating method with excellent corrosion resistance - Differences from electric nickel plating (electrolytic plating) - What color is electroless nickel plating? *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

What are the possible causes for nickel plating to rust? Surface treatment "plating" not only gives products aesthetic appeal but also imparts functions such as wear resistance and conductivity. There are various types of plating, among which "nickel plating," known for its excellent corrosion resistance and hardness, is commonly used. Although nickel plating is highly resistant to corrosion and rarely rusts, we occasionally receive inquiries about "products with nickel plating rusting." In this column, Ebina Denka Kogyo, a plating company, will explain in detail the causes of rusting in products that have been nickel plated. [Contents (excerpt)] ■ What are the causes of nickel plating rusting? ■ Causes of rusting in nickel-plated products ■ Occurrence of pinholes (pitting) *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The thickness of electroless nickel plating is deeply related to the durability of the product, making knowledge of thickness a very important point. In this column, we will discuss electroless nickel plating, including an overview (features, etc.), types, differences from electroplated nickel, and thickness. We will also introduce our company, Ebina Electric Chemical Industry, so please take a look for reference in manufacturing. [Contents (excerpt)] ■ Explanation of the thickness of electroless nickel plating ■ What is electroless nickel plating? ■ "Features" Uniform thickness! Suitable plating for precision instruments and complex shapes ■ Applications of electroless nickel plating ■ Types of electroless nickel plating *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This column explains the mechanism of heat sinks. Heat sinks are important components of high-performance electronic devices. We will introduce the mechanism of heat dissipation, the materials used, and our technology "Sugohie," which can further enhance heat dissipation, by the functional plating company, Ebina Denka Kogyo. [Contents (Excerpt)] ■ What is the mechanism of heat sinks? An explanation of the mechanism that supports high-performance electronic devices. ■ About heat sinks. ■ Reasons why heat sinks are necessary for high-performance electronic devices. ■ The mechanism of heat dissipation using heat sinks. ■ The mechanism of heat dissipation. *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this column, Evina Denka Kogyo, a functional plating manufacturer, will explain the basic information about aluminum's thermal properties (specific heat, thermal conductivity, etc.), comparisons with other metals, and the applications of aluminum that leverage its heat dissipation effects. We will also introduce our technology that improves thermal transport efficiency, so if you have any issues regarding heat dissipation, please feel free to consult us. For more details, please refer to the related links. 【Content Overview (Excerpt)】 ■ Introduction to basic information about aluminum's specific heat, thermal conductivity, and our technology ■ What is specific heat? ■ What is heat quantity? ■ Specific heat and heat capacity ■ What is thermal conductivity? *For detailed content of the column, you can view it through the related links. For more information, please do not hesitate to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This article explains the principles of heat sinks and the mechanisms of heat dissipation. Our company has a technology called "Sugohie" that enhances the heat dissipation properties of heat sinks and similar products. In this column, we will introduce not only the principles of heat sinks but also the principles and benefits of "Sugohie." If you are considering improving heat dissipation performance, please take this as a reference. 【Contents (excerpt)】 ■ A clear explanation of the principles of heat sinks ■ What is a heat sink (radiator)? ■ The principles of heat sinks and the mechanisms of heat dissipation ■ Reasons why heat sinks are necessary ■ Heat sinks and thermal resistance *For detailed content of the column, you can view it through the related links. For more information, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Separators (for fuel cells) are used to seal the cells. In addition, there are other performance characteristics, and development and research are being advanced with the aim of promoting fuel cells, but currently, the corrosion degradation of materials is a challenge in development. In this column, we will introduce surface treatments and plating to enhance the corrosion resistance of separators for fuel cells. 【Contents (excerpt)】 ■ Separators are one of the components that make up a fuel cell ■ Characteristics and materials of separators for fuel cells ■ Role of separators ■ Materials of separators ■ Carbon separators ■ Metal separators *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The electrode materials for fuel cells are one of the development challenges. In particular, platinum (Pt), used as an electrode catalyst in one type of fuel cell, the polymer electrolyte fuel cell (PEFC), is highly valuable due to its rarity. Research is being conducted to reduce costs, and in addition to cost reduction, the materials for fuel cell electrodes are required to have corrosion resistance, impact resistance, and high performance for standardization. In this column, we will provide a detailed introduction to the materials used in the electrode parts of fuel cells. [Excerpt of Contents] ■ The electrode materials for fuel cells vary depending on the electrolyte ■ What is a fuel cell? ■ Materials for the electrode catalysts of the currently popular polymer electrolyte fuel cell (PEFC) ■ Structure of polymer electrolyte fuel cells (PEFC) and performance of electrode catalysts ■ Reasons why Pt-based materials are used in polymer electrolyte fuel cells (PEFC) *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Fuel cell cells are essential for generating electricity through the chemical reaction of oxygen and hydrogen. In this column, we will thoroughly explain the structure of the cells and the principles behind electricity generation. We will also introduce why the development of fuel cells is being advanced for general use, along with their applications. [Content Overview (Excerpt)] - Fuel cell cells are the basic units of composition - A thorough explanation of the structure of cells that generate electricity using oxygen and hydrogen - Structure of the cells - Principles of electricity generation *For detailed content of the column, you can view it through the related links. Please feel free to contact us for more information.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The fuel cell stack is the power source of the fuel cell vehicle (FCV), which is currently attracting attention. The fuel cell stack, which generates electricity using hydrogen and oxygen and is said to be environmentally friendly, will be explained in an easy-to-understand manner in this column. We will also introduce the technology of our company, Ebina Denka Kogyo, which specializes in these functional plating processes. [Contents] ■ The fuel cell stack utilizes hydrogen technology ■ The system and principles of the fuel cell stack (FC stack) ■ The structure of the fuel cell stack ■ Electricity generation through the chemical reaction of hydrogen and oxygen ■ Fuel for fuel cell vehicles *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company, Ebina Denka Kogyo, specializes in functional plating and is capable of plating for semiconductors. In this column, we will introduce the importance (role) of plating processing and our processing technology, focusing on the increasingly essential theme of "semiconductors." For more details, please refer to the related links. [Contents (excerpt)] ■ What is the relationship between semiconductors and plating? Ebina Denka Kogyo will explain! ■ About semiconductors ■ Definition of semiconductors ■ What are semiconductors? ■ Methods of semiconductor manufacturing ■ Importance of semiconductors *You can view the detailed content of the column from the related links. For more information, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

TSVs have recently attracted attention in the 3D implementation of semiconductors. Recent trends in semiconductor development suggest that the integration of ICs (integrated circuits) is expected to progress towards 3D implementation. In this context, technologies that form electrodes in the vertical direction of substrates, such as TSVs (Through-Silicon Vias), are anticipated to significantly contribute to the 3D evolution in the semiconductor field. In this column, we will introduce TSV technology and our development of "Through-Glass Vias (TGV)" based on trends in the semiconductor sector. [Contents (Excerpt)] - TSVs are an important technology for 3D implementation of semiconductors! An overview of the current situation and challenges. - Semiconductor development is moving towards 3D implementation. - Important technologies for 3D implementation of semiconductors! *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

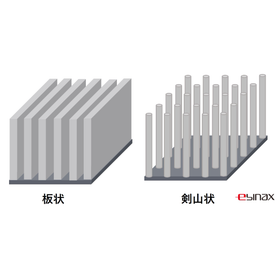

This column explains the heat dissipation effects of changing the shape of heat sinks and the types of heat sink shapes. Additionally, for those who cannot change the base material or want to enhance cooling effects at low cost, we also introduce our plating technology called "Sugohie." For more details, please refer to the related links. [Contents (excerpt)] ■ Reasons to change the shape of heat sinks ■ The function and mechanism of heat sinks ■ Types of heat sink shapes ■ What to do when the shape of the heat sink cannot be changed ■ The technology "Sugohie" that enhances cooling effects through plating *For detailed content of the column, please refer to the related links. Feel free to contact us for more information.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Ebina Electric Industry conducts "precision cleaning for semiconductor-related components." Applicable to precision parts that require cleanliness. Cleaning and packaging are performed in a clean room to suppress particles. Additionally, since we handle everything in-house from plating to cleaning and packaging, we can shorten the lead time for surface treatment and cleaning. 【Features】 ■ Applicable to precision parts that require cleanliness - Cleaning and packaging are performed in a clean room to suppress particles ■ In-house integrated response from plating to cleaning and packaging - Shortens lead time for surface treatment and cleaning ■ Multiple cleaning facilities tailored to materials and purposes *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The heat dissipation microtexture "Sugohie" is a technology for forming special-shaped coatings using a wet plating method. It forms micro-fins at a density of approximately 90,000 to 200,000 pieces/cm², achieving an increase in surface area at a low cost for large areas. Please feel free to consult us when you need assistance. 【Features】 ■ Wet plating method ■ Special-shaped plating ■ Surface treatment technology that enhances heat dissipation efficiency ■ Micro-fins at a density of approximately 90,000 to 200,000 pieces/cm² ■ Mass production possible at low cost for large areas *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Three Elm" is a 3D wiring formation technology provided by our company. By replacing existing substrates and harnesses with Three Elm, we can achieve substrate-less and harness-less designs, enabling space-saving, miniaturization, lightweighting, reduction of assembly work, and expansion of design flexibility. This technology can meet the demands for thinner and lighter electronic devices in mobile terminals, automobiles, medical equipment, and more, in response to the increasing functionality of these devices. 【Features】 ■ Realization of substrate-less and harness-less designs ■ Achieving miniaturization, lightweighting, and space-saving for electronic devices ■ Expansion of design flexibility through increased design freedom ■ Reduction of assembly work *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our technology, "Coating on Glass." It excels in high-frequency characteristics and has a smooth and flat surface, reducing high-frequency transmission loss. The compatible materials include non-alkali glass, quartz glass, borosilicate glass, soda-lime glass, sapphire glass, and coating on through holes is also possible. Please consult us regarding actual designs. 【Features】 ■ Reduction of transmission loss ■ Excellent high-frequency characteristics ■ Smooth and flat surface ■ Low thermal expansion rate *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our processing technology enables the creation of glass without cracks or chips, and allows for ultra-high-density fine holes. The roughness of the sidewalls of the through holes is Ra0.08μm. We can achieve smooth sidewalls, enabling miniaturization and integration of devices. The shapes of the through holes can be selected from straight, hourglass, or tapered. 【Features】 ■ No cracks or chips ■ Smooth sidewalls ■ Ultra-high-density fine holes ■ Miniaturization and integration of devices *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our "plating on ceramics" has high electrical insulation properties and excellent heat dissipation. There are two types of circuit formation methods: the "subtractive method," which has a flat circuit surface and excellent surface mountability, and the "semi-additive method," which allows for narrow pitch copper patterns. Plating can also be applied to through holes, and it is compatible with materials such as alumina, zirconia, and zinc oxide. 【Features】 ■ High electrical insulation ■ High thermal conductivity ■ Excellent heat dissipation ■ Low thermal expansion rate *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our technology not only utilizes the color and texture of titanium itself but also enables a variety of colors through anodizing treatment, which can be used to enhance decorative and design aspects. This allows for measures to prevent medical errors through improved visibility due to the diverse color palette. Additionally, it can accommodate small parts of 5mm or less. 【Features】 ■ Can be used to enhance decorative and design aspects ■ Diverse colors ■ Improved visibility ■ Capable of accommodating small parts *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The black plating "SugoKuro" suppresses light reflection due to the complexity of the surface shape, achieving a reflectance of less than 1% in the visible light range (380–750nm). It prevents stray light in optical devices such as cameras and spectrophotometers, contributing to the reduction of image noise and measurement errors. Additionally, while black paint and black anodizing using organic coatings can fade or discolor due to heat and ultraviolet light, our black plating is an inorganic coating, providing strong durability. 【Features】 ■ Reflectance of less than 1% (visible light range) ■ Thin film (approximately 3μm) ■ Heat and UV resistance ■ Prevention of outgassing ■ Compliant with RoHS directive *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have established appropriate plating processes tailored to the surface conditions and compositions of various composite materials. Metal matrix composites, which combine metals with ceramics, carbon, and dissimilar metals, are used in applications such as heat sinks, leveraging their heat dissipation properties. Plating can add value by enhancing solderability and other characteristics. By improving surface brittleness, we can enhance wear resistance, and by covering the surface with plated metal, we can also prevent dust originating from the material. 【Features】 ■ Enhancement of solderability ■ Improvement of wear resistance ■ Dust prevention measures ■ Compatibility with metal-ceramic, metal-carbon, and metal powder composites *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our technology, "Electroless Nickel Plating." By co-depositing with phosphorus and boron, it is possible to enhance corrosion resistance, hardness, and wear resistance, as well as to provide solder wettability. Electroless nickel plating is broadly classified into two types: phosphorus plating and boron plating. Phosphorus plating is further categorized into three types—low phosphorus, medium phosphorus, and high phosphorus—based on phosphorus content, each with different characteristics. We will propose the appropriate type according to the functions required by our customers. [Features] ■ Excellent corrosion resistance ■ Superior wear resistance ■ Increased hardness through heat treatment ■ Lead-free compliant *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The electric casting small jet nozzle is our company's unique patented technology that uses electric casting (electroforming) to produce nozzles. It enables the manufacturing of fine-shaped nozzles that are difficult to create through machining.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration