1~34 item / All 34 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~34 item / All 34 items

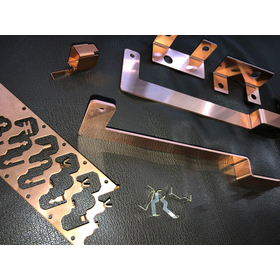

CCAC (Copper Clad Aluminum Composite) is a new type of copper-aluminum clad material that uses isothermal processing technology (patented internationally) to achieve a metallurgical bond of copper to an aluminum core. While retaining the excellent properties of copper, such as conductivity, it also combines the advantages of aluminum, being lightweight and low-cost. Unlike clad materials made by bonding dissimilar metals, it features a shape where copper completely covers the aluminum. It boasts excellent conductivity, thermal conductivity, heat dissipation, solderability, and plating properties, along with high ductility and ease of processing. It is metallurgically bonded through a controlled high-temperature isothermal process, which also prevents oxidation. In addition to drilling and bending, it can be adapted for processing operations such as deep drawing, twisting, and cutting.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Tatsumiya Metal has two faces: "a non-ferrous materials wholesaler with over 80 years of history" and "a machining manufacturer with over 30 years of experience," leveraging each function to enable cost advantages and stable supply. Equipped with 46 NC multi-tasking lathes, roundness measuring instruments, and shape measuring machines, we have established a system that can meet high standards of quality. We have numerous mass production achievements for major domestic pneumatic valve manufacturers and hydraulic equipment manufacturers, earning us a high level of trust. Additionally, we have processing achievements for lead-free brass materials compliant with RoHS2 (Mitsubishi Material Corporation's Eco Brass and San-Etsu Metal Co., Ltd.'s BZ-5), enabling us to provide integrated support from procurement to processing. *If you find yourself saying, "I can process it, but I can't get the materials..." please contact Tatsumiya Metal!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Copper materials are widely used in semiconductors, automobiles, and electrical components, and in recent years, the demand has further increased due to the acceleration of electrification (EV). Many users feel uneasy about the supply, and to ensure a more stable procurement of materials, we present Mitsui Sumitomo Metal Mining's original phosphorus-containing copper, which has been innovatively manufactured. <Features> ■ Equivalent to Tough Pitch Copper C1100 - Alternative Product This original alloy has achieved JIS C1100 compliance at Mitsui Sumitomo Metal Mining. It is phosphorus-containing deoxidized copper that has removed oxygen from copper using trace amounts of Fe and P. Its mechanical properties and specifications are in line with C1100, and its conductivity and solderability are also equivalent to C1100. The scrap evaluation is the same as C1100. ■ Supply System Since it can be manufactured within Mitsui Sumitomo Metal Mining's facilities, it can flexibly respond to shortages of materials or increases in demand, ensuring stability in the supply system. ■ Prototype Support It's common to want to try something but find that the product is unavailable, especially with new materials or alloys. At Tatsumiya Metal, we have a wide range of samples available in various thicknesses for prototyping, testing, and consideration for introduction at any time. For those feeling uneasy about the future of copper material procurement, please feel free to contact us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Chinki Metal's pipe bending and coil winding processing achieves space-saving and high efficiency through the use of small radius bends and fin tubes, accommodating both small lots and larger quantities. 【Features】 ■ Compatible materials: Stainless steel, copper, aluminum, titanium, and others (please consult separately regarding the material for fin tubes). ■ Capable of integrated production from bending processing to welding, brazing, and surface treatment! ■ Able to respond comprehensively from a single prototype! *For details or production examples, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you having trouble finding a place to put your mask when you take it off during meals? In such cases, we introduce a convenient mask case that allows you to store and carry your mask easily. Now that masks have become essential, let's protect ourselves from harmful viruses and bacteria by using the copper-based mask case "MASK REST." Additionally, by suppressing the growth of bacteria, it helps reduce unpleasant odors that may linger on the mask. <Excellent Antibacterial and Sterilizing Effects> Metals such as copper and brass containing copper have been recognized for their antiviral effects against O157, norovirus, influenza, and their antibacterial properties against harmful bacteria like Legionella. Furthermore, in 2008, the U.S. Environmental Protection Agency legally approved a label stating that it "sterilizes pathogenic microorganisms that are harmful to humans and has public health benefits" (according to the U.S. EPA's standards, sterilization refers to reducing bacteria to nearly zero within two hours). In recent years, there are also high expectations for its effectiveness against the rampant novel coronavirus.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Tatsumiya Metal's pipe bending processing can be done without molds if everything goes well, by utilizing existing molds owned by our company and partner factories. With Tatsumiya Metal's materials trading division, we have reliable knowledge of materials and stable procurement and supply. This process is widely adopted in situations where custom parts are needed, such as for repairing existing equipment piping, or in cases where you want to try it out for prototype development! For more details, please contact us or download and view our catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

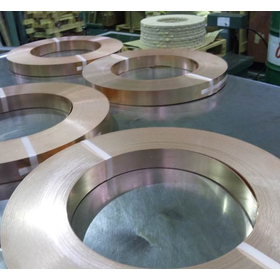

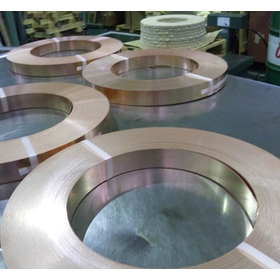

Tatsumiya Metal's metal material sales can provide high-quality non-ferrous metal materials and plated materials with short delivery times, thanks to our extensive in-house inventory and slitting equipment. Typically, the delivery time for standard material supply, such as coil materials, takes about one week to ten days. However, at Tatsumiya Metal, we maintain inventory and perform in-house processing, allowing us to ship on the same day as the order and deliver the next day at the earliest. (Note: The usual delivery time is 4 to 5 days.) The minimum lot size for coil materials is usually 2 kg/mm. For prototypes, we can provide materials in units of a few centimeters, allowing us to respond to shipping needs based on application and urgency. We also quickly accommodate requests for prototype materials in sheet form. This approach reduces inventory risk, enabling material supply only as needed when required. **Features** - Stock of various copper products and plated materials - Support from in-house and external slitting facilities - Through our supply network, we can provide and propose prototype materials in coil form and standard-sized sheets beyond our in-house inventory. - We have established a supply system through a network with domestic and international copper product manufacturers. Additionally, we can accommodate both prototypes and mass production of thick copper materials for busbars, which have seen increasing demand in recent years. *For more details, please download the catalog or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The various environmental laws and regulations represented by RoHS2, as well as the restrictions on the use of "lead" by various industry organizations, are gradually becoming a reality. At Tatsumiya Metal, we can make accurate proposals based on our extensive sales achievements in the materials division for lead-free brass alloys, silicon-based alloys represented by Eco Brass, and bismuth-based alloys, as well as our considerable experience and achievements in our own machining division. <Current Status Regarding Lead-Free Brass> - The free-cutting brass, which has about 4% lead added for improved machinability, is currently subject to exclusion regulations and is in a grace period. - Unless Europe provides accurate proposals for alternative materials, the exclusion regulations will also be abolished. - From July 21, 2021, conventional leaded brass will no longer be usable in products for industries and major companies that apply RoHS and various environmental regulations. <Current Response Status> - Various manufacturers are developing lead-free brass, and application tests are being conducted by respective users and industry organizations. - Features of lead-free products: - Bismuth-based: Alloys with bismuth added instead of lead. - Silicon-based: Alloys with silicon added instead of lead. - Low-lead brass: Brass with reduced lead content. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Tatsumiya Metal, we can make accurate proposals based on our extensive sales achievements in the material sales division of lead-free brass alloys, silicon-based alloys represented by Eco Brass, and bismuth-based alloys, as well as our considerable experience and accomplishments in our own machining division. <Current Status Regarding Lead-Free Brass> - A free-cutting brass that has about 4% lead added for improved machinability is currently subject to exclusion regulations, which are in a grace period. - Within the next 2-3 years, there is a possibility that traditional leaded brass may no longer be usable in products for industries and major companies that apply RoHS and various environmental regulations. <Current Response Status> - Various manufacturers are developing lead-free brass, and application tests are being conducted by respective users and industry organizations. - Features of lead-free products: - Bismuth-based: Alloys that add bismuth instead of lead. - Silicon-based: Alloys that add silicon instead of lead. - Low-lead brass: Brass with reduced lead content. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Amidst the restrictions on the use of "lead" in various environmental laws and regulations, free-cutting brass containing about 4% lead for the purpose of improving machinability is currently exempted due to the lack of effective alternative materials. However, prompt action is essential towards the eventual lifting of this exemption in the coming years. Additionally, since some users establish their own environmental standards, it is also necessary to be prepared to respond at any time. At Tatsumiya Metal, we can make precise proposals based on our extensive sales record in the materials division, including lead-free brass alloys such as Eco Brass, and our considerable experience and achievements in our machining division. - As a materials trading company, we have a robust material procurement network. - We possess know-how gained from our sales experience with materials. - Plus, we have processing achievements in our machining division! - We have a cooperative system with material manufacturers. - We offer various lead-free copper alloys, including silicon-based and bismuth-based options, as well as low-lead materials (there are systems that add silicon instead of lead and those that add bismuth). We have established a quality system that can meet high technical demands with 45 NC automatic lathe combination machines and high-precision measuring instruments such as roundness measuring devices and surface roughness profile measuring instruments. *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Tatsumiya Metal's metal material sales offer high-quality and short delivery times for non-ferrous metal materials and plating materials, thanks to our extensive in-house inventory and slitting equipment, as well as the ability for long-term stable supply. Typically, material supply takes about 1 to 10 days, but at Tatsumiya Metal, we maintain stock and perform in-house processing, allowing for shipment on the same day as the order and delivery the next day at the earliest. (Note: the usual delivery time is 4 to 5 days.) We also accommodate minimum lot sizes starting from 2 kg/mm, responding to various applications and urgency. This reduces inventory risk, allowing for material supply only when needed. Additionally, our strong partnership with manufacturers ensures stable supply. We consider various aspects such as usage frequency, purchase units, inventory burden on our side, and delivery pace together with our customers, aiming for stable supply in all scenarios. 【Features】 ■ Stock of various copper alloy materials and plating materials ■ Integrated supply system with three in-house slitters and partner factories ■ High-quality materials provided through years of slitting technology ■ Stable supply achieved through strong ties with manufacturers *For more details, please download our catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company, which specializes in pipe bending and the sale of special alloys, is currently offering a collection of materials to help solve your metal processing concerns. We provide useful information, including answers to questions such as "There are various types of welding, but how are they different?" and "What exactly is pipe bending?" as well as a list of availability by type and shape for issues like "I can't arrange for the alloy number specified in the drawing." 【Series List】 ■ "What is Pipe Processing?" ■ "Material Selection Data: Aluminum Availability List" ■ "Material Selection Data: Pipe Edition" ■ "Material Selection Data: Copper Alloy Availability List" ■ "Material Selection Data: Cutting Processing Edition" ■ "Weldability Data" *You can download the materials as PDF data from "Download Catalog" or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Have you ever had an experience like this? ○ Unfamiliar drawings... Cutting? Pressing? It looks like a spring, but... It's pipe bending! But how do you do it? ○ I don't really understand the drawings for pipe bending, the design of piping components, the design of heat exchangers, or how to select the material and size of the pipes. ○ Welding sounds easy to hear about, but when it comes to actually giving instructions, I don't know how to do it... Having dealt with pipe bending and the processing of piping components for many years, and being originally a materials trading company, Tatsumiya Metal understands the characteristics and points of processing technology. We will introduce materials that compile technical know-how! For more details, please download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

While selling metal materials, Tatsumiya Metal, which has been involved in metal cutting processing for many years, understands the concerns during material selection. The "Material Selection Guide (Cutting Processing Edition)" is a one-page table that clearly presents information for selecting cutting materials at a glance. Please add this to your technical documentation. This is useful in situations like: ○ Brass is good for machinability... but stainless steel is better for cost... which one to choose? ○ A request for cost reduction from the end user! We need to reconsider the material... ○ We haven't noticed it for years, but are there actually other suitable materials? *For more details, please download the document. If you have any questions, please feel free to contact us♪

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Because Tatsumiya Metal has been handling welding and brazing along with pipe processing for many years, we understand the questions surrounding welding. "Pipe Processing Technical Documentation: Welding Edition" is a reference book on welding. Have you ever had experiences like these? - You often hear about welding and thought it was simple, but there are various methods, and you don't know which method to instruct. - You are unsure if the material you have on hand is suitable for welding. - What is the difference between welding and brazing in the first place? This document aims to address such questions by focusing on two basic points and providing explanations.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Unfamiliar drawings... Cutting? Pressing? It looks like a spring too... It's pipe bending! But how do you do it?" Have you ever had such an experience? We have prepared basic technical materials on the theme of "What is pipe bending?" For more details, please download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The small R pipe bending processing is a technology that allows for compact processing with a smaller bending radius than conventional methods. It enables the compactness of heat exchangers and piping components, contributing to the overall compactness of our customers' products. This technology has also been introduced in aircraft piping components, achieving efficient piping arrangements in limited spaces and contributing to quality improvement. Additionally, we have introduced the Opton NC pipe bender! We will propose the optimal processing methods for pipe processing, not limited to the use of the NC pipe bender.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Amidst the restrictions on the use of "lead" in various environmental laws and regulations, free-cutting brass that contains about 4% lead for the purpose of improving machinability is currently exempted due to the lack of effective alternative materials. However, in light of the potential removal of this exemption in the near future, it is essential for automobile and electronics manufacturers, as well as the parts processing companies supplying them, to respond promptly. Additionally, since some users establish their own environmental standards, it is also necessary to be prepared to respond at any time. At Tsumiya Metal, we can make accurate proposals based on our extensive sales record of lead-free brass alloys, particularly "Eco Brass," and our significant experience and achievements in our own machining division. ● As a material trading company, we have a robust material procurement network. ● Know-how gained from sales experience as a material supplier. + Machining achievements in our processing division! ● Collaborative system with material manufacturers. ● Options available for silicon-based and bismuth-based lead-free copper alloys, as well as low-lead materials (each manufacturer offers variants with silicon or bismuth added as substitutes for lead).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Stainless steel is difficult to machine and expensive, so I dislike it! I can manage for prototypes, but mass production is..." Such voices can still be heard even in today's advanced technological world. If you are struggling with machining on NC automatic lathes, please reach out to us. We have gained high trust through numerous achievements in the fields of pneumatic valve manufacturing and hydraulic equipment. We have established a quality system that can meet high technical demands with 47 NC automatic lathe combination machines and high-precision measuring instruments such as roundness testers and surface roughness profile measuring devices. Additionally, as a company specializing in materials, Tatsumiya Metal offers unique advantages in material procurement, ensuring stable supply and responsiveness to cost requirements. 【Features】 ■ Stainless steel (SUS303, 304, 316, etc.), aluminum ■ Brass, cadmium-free, and lead-free options are certainly available ■ Extensive experience in high-quality demanding fields such as automotive, hydraulic, and gas *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Ecobras" is a lead-free copper alloy that does not use lead. It is a groundbreaking high-performance material that serves as an alternative to conventional lead-containing free-cutting brass, while simultaneously solving issues related to stress corrosion cracking and dezincification corrosion. ● Excellent machinability In conventional free-cutting brass (C3604), the lead in the metal structure improves machinability. In Ecobras, the addition of silicon forms κ and γ layers, which fragment the chips and enhance machinability. ● High strength comparable to stainless steel The tensile strength of Ecobras is 600 N/mm². It is a high-strength material comparable to stainless steel SUS304, with a strength 1.4 times greater than conventional brass materials. This allows for cost reductions through thinner and more compact products. ● Solves dezincification corrosion issues Ecobras has a low zinc content in the alloy and does not contain the electrochemically noble β phase in the matrix, preventing dezincification corrosion. ● Solves stress corrosion cracking issues The reduction of zinc content, along with the addition of silicon, effectively addresses the problem of stress corrosion cracking. ● Excellent hot forgeability (equivalent to forging brass C3771) ● Superior solder wetting, brazing, and plating properties.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Have you ever had such an experience? ○ You created a new drawing, but you're worried if this material really exists in the world... ○ It's a drawing for a shape processed from a rod, yet the alloy number for a plate is specified... ○ The material with the specified alloy number in the drawing cannot be procured. It is indeed listed in the JIS standards, but... Chemical compositions and mechanical properties are easily obtainable. Typically, designers specify the best material among them in the drawings. However, the actual availability of that material when doing the work tends to be overlooked. This is understandable since there are no such references or literature available. Therefore, I hope you can use this "Availability List" as a reference to assist you in your work.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Have you ever had such an experience? ○ You created a new drawing, but you're worried if this material really exists in the world... ○ It's a drawing for a shape processed from a rod, yet the alloy number for a plate is specified... ○ The material with the specified alloy number in the drawing cannot be procured. It is indeed listed in the JIS standards, but... Chemical composition and mechanical properties data are easily accessible. Typically, designers specify the best material in the drawing, often overlooking the availability of that material itself. This is understandable since there are no such references or textbooks available. Therefore, I hope you can use this "Availability Reference Table" as a helpful resource for your work.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our pipe bending processing utilizes existing molds owned by our company and partner factories, allowing for production of one piece without the need for molds if everything goes well. With Tatsumiya Metal, you can expect reliable knowledge of materials and stable procurement and supply. This service is widely adopted for custom parts in prototype and development settings, as well as for repairs of piping in older equipment! For more details, please contact us or download our catalog to take a look.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have a large inventory centered around copper and brass at our headquarters coil center. We achieve small lot and short delivery times with four slitting machines of various sizes. <Features> ◆ Stock of various non-ferrous metal materials and plated materials ◆ Immediate delivery system with four slitting facilities ◆ One of the few in the non-ferrous industry to accommodate thick materials up to 3.5 mm ◆ Providing high-quality materials with years of slitting technology ◆ Capable of handling small quantities (basic minimum lot weight kg/mm) ◆ Prototype support available (special cutting and provision of units such as a few centimeters or several meters for prototype purposes)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Chinki Metal's pipe bending processing can accommodate everything from small lots to mass production. We have experience with materials such as stainless steel, copper, aluminum, titanium, and special metals like Inconel and Hastelloy. In addition to bending, we can also handle welding, brazing, heat exchanger coils, and can respond comprehensively from a single prototype. Furthermore, leveraging the regional characteristics of Higashi-Osaka, we meet diverse needs through collaboration with various processing genres. 【Features】 - Supports everything from small lots to mass production - Experienced with stainless steel, copper, aluminum, titanium, and special metals like Inconel and Hastelloy - Capable of comprehensive support for bending, welding, brazing, heat exchanger coils, and from a single prototype *For production examples, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Copper alloys that contain copper, such as copper and brass (the material of the 5 yen coin) and nickel silver (the material of the 100 yen coin), have antibacterial properties. For example, simply using them in areas that are frequently touched, such as handrails and door handles, can provide these benefits. They are particularly noted in hospitals and schools for preventing hospital-acquired infections, being used in bed frames and medical trays, as well as attaching brass tabletops to desks and using ballpoint pens with copper grips, effectively reducing the spread of bacteria.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Pipe parts, elofin tubes used in heat exchangers and piping (pipes with plate-like fins called fins). At Tatsumiya Metal, we can bend pipes with fins just like conventional pipes. We can also provide pipe materials alone. If we have a mold of a similar size, we can save on mold costs. For more details on pipe processing, please download our catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The overseas copper market, LME inventory, domestic and international economic trends, crude oil prices, supply and demand balance, futures speculation, exchange rates... the metal markets, including copper, change dramatically every day due to various factors. Users who utilize various types of copper and copper alloys must be facing daily challenges. (Even we, who handle it somewhat professionally, find it difficult to understand.) Please feel free to use this for analyzing past trends and as reference material for the future.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Chinki Metal offers pipe processing, pipe bending, coil winding, and piping component processing, catering to both small lots and large quantities. We work with materials such as stainless steel, copper, aluminum, titanium, and also have experience with special metals like Inconel and Hastelloy for pipes and various piping. We can handle pipe bending and other pipe-related processing, as well as welding, brazing, heat exchanger coils, piping components, and prototypes from a single piece to a wide range of needs. We can also work with pipe materials alone. Additionally, leveraging the regional characteristics of Higashi-Osaka, we respond to diverse needs through collaboration with various processing genres beyond just pipes. 【Features】 - Pipe processing available from small lots to large quantities - Proven experience with special metals and materials - Capable of handling prototypes from a single piece to a wide range - Collaboration with various processing genres beyond pipes and piping - One-time use is possible when regular suppliers cannot arrange pipe processing or piping components - We can also accommodate pipe materials alone, not just pipe processing or piping components For more details, please contact us or download our catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Chinkiya Metal's pipe bending and coil winding processing can accommodate a wide range of quantities, from small lots to large volumes, and is capable of handling materials such as stainless steel, copper, aluminum, titanium, as well as special metals like Inconel and Hastelloy. 【Features】 ■ Available materials: Stainless steel, copper, aluminum, titanium, and special metals like Inconel and Hastelloy with proven results. ■ Capable of integrated production from bending processing to welding, brazing, and heat exchanger coils! ■ Can respond comprehensively from a single prototype! *For details or production examples, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Numerous achievements in difficult-to-machine stainless materials, including SUS304 and SUS316. Maximize the advantages of material procurement unique to Tatsumiya Metal, which has the face of a materials trading company. Also, if you are considering lead-free brass, please feel free to contact us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Chinki Metal's pipe bending processing accommodates everything from small lots to mass production. Materials include stainless steel, copper, aluminum, titanium, and we also have experience with special metals such as Inconel and Hastelloy. In addition to pipe bending, we can handle welding, brazing, heat exchanger coils, piping components, and more, from prototype production to comprehensive support. Furthermore, leveraging the regional characteristics of Higashi-Osaka, we respond to diverse needs through various pipe processing and collaboration with other processing genres. ● For examples of our work, please download our catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Tatsumiya Metal, with over 80 years of history, combines the face of a manufacturer specializing in pipe bending and NC precision cutting processing, the sale and processing of non-ferrous metal materials, and the sale of ceramic heaters, functioning as a trading company. If you have any issues regarding metal materials or processing, come to Tatsumiya before you encounter problems! ○ We specialize in metal pipe processing. In the world of bending processing, where small lots are common, the presence or absence of molds becomes quite important. We propose a mix of our own molds and equipment, as well as those from partner factories. ○ With 80 years in the non-ferrous metal industry, we have been supported by a wide range of clients, from major corporations to technical professionals in Higashi-Osaka. ○ Tatsumiya Metal's comprehensive capabilities, backed by in-depth knowledge of materials, allow us to demonstrate our proposal power and procurement advantages in the field of precision cutting processing. ○ Although not metal, we also handle ceramic heaters as part of our trading company functions. *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Tatsumiya Metal Co., Ltd. Kyotanabe Factory, we have approximately 30 units of combined CNC automatic lathes and CNC automatic lathes. In addition, we are equipped with quality inspection devices and measurement equipment, including surface roughness and contour measuring instruments, roundness and cylindrical shape measuring instruments, and measuring (optical) microscopes/image measurement systems. We have established a system to meet high demands in quality. ● For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration