It prevents the deposition of powder regardless of the pipe shape, prevents clogging in the pipes through localized concentration, and extends the performance of the pump.

The exhaust line of semiconductor and liquid crystal manufacturing equipment is constantly at risk of contamination and blockage due to large amounts of powder. This product utilizes existing dilution N2 gas to easily and cost-effectively prevent and resolve these issues. Additionally, it significantly improves the overhaul cycle and lifespan of cryopumps, as well as demonstrating excellent effectiveness in purging load lock chambers.

Inquire About This Product

basic information

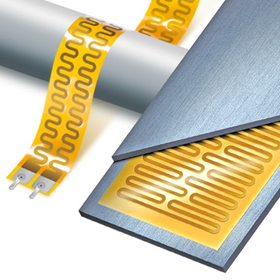

In CVD equipment and vacuum pumps for dry etching devices, issues such as deposition accumulation, vacuum pump failures, and valve blockages frequently occur between the vacuum pumps and the exhaust treatment devices. This product mitigates these problems by locally flowing high-temperature N2 gas through the piping immediately after the pump (or inside the pump), thereby improving the conventional pump life and enhancing the stable operating rate of the equipment. It is easy to install, can utilize existing N2 inlet points, and can be incorporated into the exhaust piping. It has also been adopted as an option by a certain pump manufacturer and specified for particular users, so its effectiveness is expected. The heater has a built-in leakage detection function, ensuring minimum safety measures without the need for a leakage breaker. The nitrogen flow rate is standard at 30-50 L/min, with a temperature range of 100-200°C, input AC 200V, 300W. N2 temperature and flow monitoring, as well as internal and external temperature monitoring of the heater body, are displayed as error messages on an LCD. The above settings can be modified according to customer requests. Additionally, there are types available that cater to large powder materials (for LCD and solar cell applications).

Price range

P4

Delivery Time

P4

Applications/Examples of results

After the pumps such as CENTURA (CVD/ETCH), CONCEPT2, and M308, there is a reduction in deposit accumulation, improved vacuum pump life, decreased exhaust pipe troubles, and reduced valve blockage issues, showing effects of 2 to 5 times or more before and after use (based on actual results).

Company information

Company Name: Evan Reed Co., Ltd. Capital: 11 million yen Headquarters: 1-1-1 Nishi-Shinagawa, Shinagawa-ku, Tokyo, 9th Floor, Sumitomo Realty & Development Osaki Garden Tower Business Overview: 1) Design, development, manufacturing, and sales of cost reduction services for semiconductor manufacturing equipment (from 3 inches to 12 inches) 2) Sales of stainless steel alternative materials (for elevators and escalators) Authorized domestic general sales company for Linopack Co.

![[Technical Information] Thermal Properties of Various Gases](https://image.mono.ipros.com/public/product/image/9a5/2000730272/IPROS74522393126133540607.jpeg?w=280&h=280)