I would like to briefly introduce the successful exhibition content of FPC.

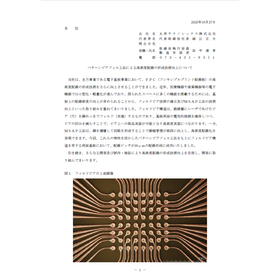

◎Introducing Our Company's "Strengths" in the Processing Engineering >> There are multiple important processing steps in FPC manufacturing. Improving the "strengths" of each step directly leads to advancements in technology and quality, as well as new product development. We have introduced the "strengths" we have cultivated over many years in each process: <Design> Circuit design, artwork, S-parameter analysis <Layer Connection> Build-up FPC, filled vias, small-diameter vias <Circuit Formation> MSAP method, thin copper, thick copper <Insulation Processing> High-precision openings ±20μm, LCP coverlay <Surface Treatment> Standard NiAu to special plating options (Ni-Pd-Au, direct Au, etc.) <Post-Processing> High-precision contour processing ±50μm, a variety of tools <Mounting Assembly> Solder mounting, ACF bonding, wire bonding, ultrasonic joining, EMS support ◎Introducing Samples of Each Processing Step During Manufacturing >> Normally, there are no opportunities to see anything other than the finished product, but we have provided a chance to view the actual samples of the processes involved in FPC manufacturing. *Through-hole drilling, exposure/development, etching, contour processing, etc.

Inquire About This Product

basic information

* Flexible Printed Circuit Board * FA (Factory Automation) * Final Appearance Inspection System For more details, please contact us at the information below. Taiyo Techno-Rex responds to various inquiries from customers. Contact Information: Head Office Wakayama: 073-431-6312 Tokyo Office: 03-6275-0690

Price range

Delivery Time

Applications/Examples of results

Please leave the FPC design, prototype production, small to medium lot mass production, and implementation to us. We propose systems suitable for final appearance inspection of high-precision substrates, ceramics, and more, utilizing material handling and collaborative robots for FA and automation. For detailed information such as photos of the exhibition venue and exhibits, please refer to the catalog "Exhibition Report_JPCAshow2025." https://pr.mono.ipros.com/taiyo-kougyo/catalog/

catalog(21)

Download All Catalogs

News about this product(3)

Company information

Taiyo TechnoRex Co., Ltd. continues to operate in the fields of prototype development of flexible printed circuit boards (FPC) and printed circuit board testing systems. Since FPC is fundamentally related to the structure of hardware, both high precision quality and shortened development time are required. We have extensive experience and know-how in the manufacturing processes of single-sided FPC, double-sided FPC, multilayer FPC, and their advanced types, and we continuously improve and enhance our technology, resulting in consistent evaluations of our delivery times and quality. Additionally, while technically advancing further miniaturization and high density, we are also undertaking new initiatives such as bump-type and special material electroplating. On the other hand, our printed circuit board testing systems mainly consist of electrical inspection systems and final appearance inspection systems, which are adopted in the mass production sites of FPCs and package/module-type substrates. They operate day and night in quality control settings for substrates used in smartphones, automotive applications, and various electronic devices. We will continue to respond to the increasingly diverse market needs. *On December 21, 2023, the company name was changed from "Taiyo Kogyo Co., Ltd." to "Taiyo TechnoRex Co., Ltd."*