[Press Release from Taiyo TechnoRex] Regarding the Improvement of High-Density Wiring Formation Technology Using the Patterned Beer Fill Method

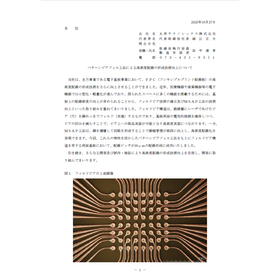

Our company has further improved the technology for forming high-density wiring in our core business of electronic substrates, specifically in flexible printed circuit boards (FPCs). In recent years, electronic devices such as medical equipment and industrial machinery have been advancing in miniaturization and lightweight design. To incorporate many functions into limited space, there is a demand for increased wiring density on the substrate. Therefore, we have been working on establishing filled via technology and improving the M-SAP method. The filled via structure involves filling vias (holes) made by laser in the insulating layer with copper plating, ensuring electrical connections on both sides of the substrate while reducing the recesses of the vias, which allows for component mounting on the vias and leads to high-density mounting. On the other hand, the M-SAP method significantly improves line width management by laminating copper to form circuits, enabling high-density wiring. This time, based on the pattern via fill method that leverages these characteristics, we successfully formed wiring with a pitch of 30μm on a double-sided substrate with a filled via structure. We will continue to aim for further improvements in high-density wiring formation technology through ongoing development, prototyping, and verification.

Inquiry about this news

Contact Us OnlineMore Details & Registration

Details & Registration