Oil-free standard non-conforming guide rails treated with nitriding! We will strengthen measures against galling and grease splatter!

A Taiwanese mold specialist manufacturer of liquid silicone rubber injection molded products and molds.

Aiming to strengthen the automotive industry's supply chain in the Tohoku region: The Ichinoseki factory (Iwate) can handle everything from mold production to emergency repairs locally!

Laser micro-hole processing: microfabrication, micron level, needles, medical industry

Lightweighting of automotive components! We offer a full range of engineering services for product development. *Lightweighting case study materials available.

You can download basic knowledge about "strength design" for free.

You can download basic knowledge about injection molding die design for free.

Surprisingly unknown wide design patterns of embossed processing! An introduction to embossed processing that enhances the design quality of products, such as stitch thread patterns and glossy finishes.

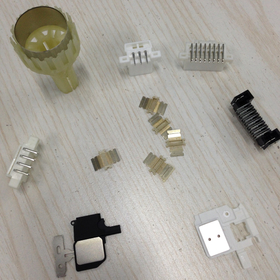

We present materials that clearly introduce the design for processing products made of metal, carbon, and plastic (resin) through photos, featuring the technology of embossed processing.

Responding to customer needs! For any issues with plastic, come to NAP with its flexible production system!