The difficult-to-obtain FCD600 (ductile cast iron) is made available with a short delivery time by leveraging the strengths of steel suppliers with inventory! *Used for sliding surfaces of machinery and wheels, etc.

Free technical materials available! We propose suitable solutions tailored to various substrates!

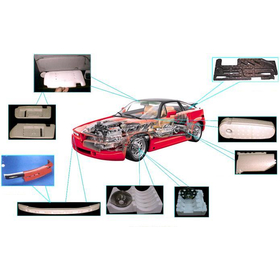

Automotive components made from foamed molded products that allow for lightweight design, low cost, and free design.

Combining the technology cultivated by a car prototype manufacturer, we challenge the production of drones! Achieving sufficient "rigidity" and "lightness" to lift an aircraft with a maximum takeoff weight of 250 kg.

Ideal for vehicle transport at automobile factories, vehicle transport in large parking lots, changing display vehicles at car dealerships, and moving broken-down vehicles (roadside assistace).

Isn't it messy where the forklift has run? Beautify the factory floor with colored tires.

We support "monozukuri" with reliable products and meticulous services!

By developing products tailored to their intended use and situation, and through quality assurance that includes domestic bracket assembly, JIT delivery, and reaction force testing, we achieve overall cost reduction.