Achieves both high speed and high precision, allowing for simultaneous work with both hands while holding the workpiece with one hand!

This is a tabletop circuit board cutting machine that can perform outline processing of circuit boards using a router cutting method. It does not require the installation of a dust collector, allowing for space-saving installation.

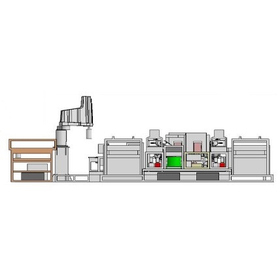

Achieve both efficiency and mistake-proofing through automatic detection! It is possible to build a flexible system with a transport system and dual-arm robots. (FA automation implementation case)

Smart cable management! An industrial robot that can be compacted and used in a space-saving manner!

Pursuing high-precision operation with a high-rigidity arm and servo control! A horizontal multi-joint industrial robot!

From transporting small parts to high-precision assembly work! A horizontal multi-joint industrial robot!

Automating deburring by robots with skilled operators, achieving labor savings and stable quality!

Automate the picking and alignment of fine parts for optical units, replacing the tasks of skilled workers with robots!

We have introduced a high-speed robotic system into the packaging process of the retort food factory, achieving labor reduction and a significant increase in production capacity!

A new robotic system has been introduced in the bento container assembly process at the food factory! Significant reduction in personnel has been achieved! It also alleviates the burden on workers in a chilled environment.

A new robot system has been introduced to the inspection sub-process of tablet molds in a pharmaceutical factory! A system has been realized that performs transportation and palletizing with a single robot!

A new robot system has been introduced in the packaging sorting process of pharmaceutical factory blister packs! Line stoppages have been eliminated, achieving an increase in production capacity!

Increased productivity! Introducing actual robot implementation cases for transportation, packaging, assembly, picking, etc.

Easy to introduce and easy to move with casters! It is an innovative dual-arm scara robot that can work alongside people!

Food-grade grease and hygiene jacket specifications make it a great asset in food factories! Easy to introduce and equipped with casters for easy movement!

A breakthrough in the difficult implementation that had given up on reducing manpower and automation! Development of a soldering robot. Achieving both tact and quality!

What we want is not just a standalone robot, but a total solution! We will introduce our efforts in the robotics business through Hanamaru's case studies!

Protection from flying debris, heat insulation, prevention of deterioration due to abrasion, and prevention of dirt adhesion and corrosion for robots, machinery, wiring, piping, and other high-strength heat-resistant fiber products!

Achieving cost reduction for enclosures: What is deep drawing and large-scale molding that reduces assembly and maintenance labor?

A "coating-specific" package that allows for easy setup with dedicated software and achieves high-precision coating with correction functions!

Completely solve issues such as labor shortages, quality inconsistencies, and barriers to implementation costs! A comprehensive collection of case studies from conceptual design of robot implementation, system construction, to proposals for utilizing subsidies!

A robotic solution to automate the assembly of electrical components and inspection after assembly!

Realizing smart factories! Planning to showcase products such as high-speed transport, human collaboration, and support for a variety of types.

An electric gripper that achieves high-precision control of gripping force, position, and speed through closed-loop control using a stepping motor and a rotary encoder.

![0_logo[1].jpg](https://image.mono.ipros.com/public/company/image/c4c/2006029/IPROS71427954949837207986.jpeg?w=280&h=280)