Achieves both high speed and high precision, allowing for simultaneous work with both hands while holding the workpiece with one hand!

Space-saving! Avoid interference with peripheral devices! An industrial robot that can operate in narrow areas.

Top-level speed and precision! Space-saving! Two units can be installed in the space of one worker! An industrial robot capable of working in narrow areas.

We have received an order for the production of an automated bush pressing device with a minimum estimate of half a day.

Overcoming automation challenges! A clear introduction to how collaborative robots have solved key issues in recruitment and tasks.

Transport, clean, refine, measure! Robot lines will operate for each ordering company!

Resolve labor shortages, quality inconsistencies, and inspection errors with "complete automation"! One-stop support from conceptual design to operational assistance, successfully reducing initial costs through the use of subsidies.

Combo of robot and gripper! Complete the task by performing two different assembly cycles.

Usability has improved further with the version upgrade! Now compatible with industrial networks "Ethernet."

For exterior inspection of automotive components. Achieving multi-point, high-speed inspection through mechanical mechanisms!

Reinforcement assembly by robots! Productivity increases the longer monotonous and repetitive tasks are performed.

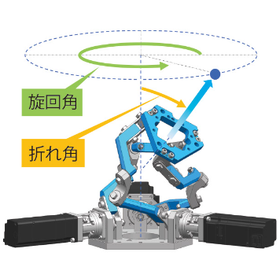

Flexible movement! A powerful 7-axis robot arm from NACHI that enables complex operations with a 20kg payload.

Space-saving design with waterproof specifications! A multipurpose handling robot that can freely perform a wide variety of tasks.

Capable of handling harsh environments! A powerful and compact multipurpose robot.

Pursuing high-speed motion! A compact robot that meets all the needs of production sites at a reasonable price.

Smart cable management! An industrial robot that can be compacted and used in a space-saving manner!

Pursuing high-precision operation with a high-rigidity arm and servo control! A horizontal multi-joint industrial robot!

A low-power type under 80W that does not require safety measures! It is a 4kg portable compact handling robot that can operate in small spaces and tight areas.