Solve the "challenges" of production technology from upstream concepts. Complete the automation of large, heavy, and diverse products.

Improving machining accuracy of machining centers through numerical correction contributes to solving issues in the manufacturing site, such as "uniformity of processing quality" and "reduction of startup time."

We will cover the gap with our organizational strength as we cannot secure specialized technicians and the increase in personnel is not keeping up! We will respond all at once to machinery, electrical, control, software, and molds.

Consistent support for local exhaust in workplaces handling organic solvents, toxic gases, and dust! Comprehensive services from estimation and construction to reporting to the Labor Standards Inspection Office.

Emergency sanctuary for precision sheet metal processing" - We respond to our customers' "manufacturing" needs in a wide range of processing areas, leveraging "connections between people.

We can provide cross-sectional and integrated design know-how for a wide range of industries, including the creation of various assembly drawings, three-view drawings, perspective drawings, development drawings, and exploded views.

Continuing to meet a wide variety of requests for about 50 years. Providing consistent support from design, processing, and assembly to after-sales follow-up.

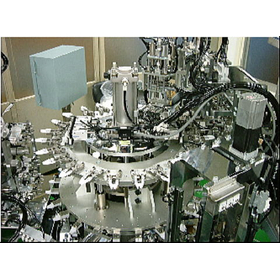

Custom manufacturing of automated machines in all fields! Numerous achievements with major automotive and cosmetics manufacturers!

You can download basic knowledge about CAE thermal analysis for free.

Based on over 20 years of continuous work experience with Japanese companies, we propose a reduction of up to 50% in design time and cost savings through outsourcing design.

Leave the design and manufacturing of production equipment to us! We handle everything from the design, manufacturing, management, and maintenance of inspection devices, testing equipment, and production jigs and tools.

A metal processing industry focused on technical proposals that achieve "one product, one style."

Unmanned operation of processing machines, molding machines, etc.!