[Case study available] Significant reduction in component costs through overseas production and process improvements! Specific examples of shortened lead times and enhanced quality are now publicly available.

We needed 20,000 lead processing units in four weeks, but there were no companies available to handle it, so this is a case where we received a request from our company.

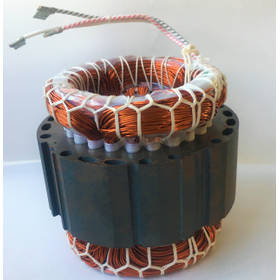

For entrusted design and manufacturing of plastics and electrical/electronic equipment, please leave it to Takawa Electric Industry, known for its trust and proven track record.

Leveraging abundant experience and technical expertise to provide high-quality chemical products. Equipped with a variety of analytical instruments, we also ensure thorough quality control.

The electronic gun is a telefocus type made by pro-beam! Please feel free to consult us when you need it.

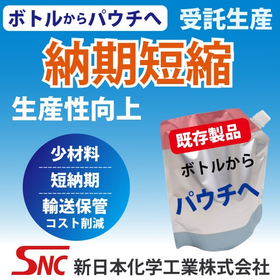

Support from product planning to filling, processing, and shipping for additives, cleaning agents, chemicals, deodorizing and disinfecting agents, etc.! For those who have raw materials but no place to fill them.

Far superior in corrosion resistance and plasma resistance compared to protective films created by thermal spraying or aerosol deposition! Yttrium oxide produced by a unique ion-assisted deposition method.

1 piece or more - production OK / contract processing OK / bring-in OK! Production of acrylic products such as acrylic stands (Acrylic Stand) and acrylic keychains (Acrylic Key)!

A miniature model of a purification tank reproduced at a 1/4 scale. Made of transparent PVC. It replicates the actual water flow and the movement of the fluid carrier due to aeration.

Responding to the impact of dimensional shrinkage rates and mechanical strength with Bakelite processing know-how.

The texture of washi remains the same, and with the technology for making it fireproof, the variations are limitless.

Contract filling manufacturing. Hazardous materials are also acceptable! We fill liquids from small quantities to large lots. We handle everything from processing and packaging to delivery!