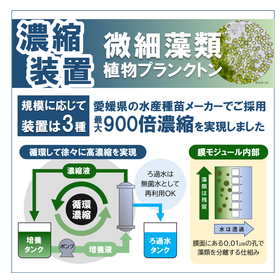

Adopted by a fishery seed manufacturer! Achieving up to 900 times concentration with UF membrane equipment.

For wet centrifugal classification/separation! It is possible to separate (concentrate, remove) submicron particles in a short time.

For the treatment of liquids containing non-volatile components! Suitable for thermally unstable substances due to reduced pressure operations.

No need for large-scale civil engineering work! Introducing a revolutionary system that can handle drainage and dewatering in one process.

Excellent dewatering effect with pressure dehydration using the front section concentration mechanism and the revolutionary filter cloth "IK-Ron Mesh"!

User report presentation! Case study on the introduction of the replacement of the old and new "TurboVap LV".

Non-contact, resistant to contamination, and highly efficient! Maintenance and cleaning are also easy! *Includes explanatory materials that highlight the differences from conventional types.

Non-contact, resistant to contamination, and highly efficient! Maintenance and cleaning are also easy! *Includes explanatory materials that highlight the differences from conventional types.

It is possible to evaporate and separate multi-component solutions and solids! A versatile device that can be widely applied!

Achieving business improvement and reducing environmental impact through concentration technology! Suppressing carbon dioxide emissions.

Katsuragi Industries - Drying Equipment, Cooling and Solidification Equipment, etc. - Comprehensive Catalog Available for Free Distribution

This is a Japanese-made concentrator designed for industrial use. It can be easily introduced due to its simple installation and maintenance.

Ishikawa-type stirring and grinding machine that can stir and crush materials containing molten material while heating.

Can grind even 0.5g of material. Can be used in glove boxes or draft chambers due to its ultra-compact size. Equipped with a timer and speed adjustment function.

![logo1[1].gif](https://image.mono.ipros.com/public/company/image/e0e/2044822/IPROS95786684133903225385.jpeg?w=280&h=280)