A compact film thickness gauge that can measure "coatings" and "coating thickness" in a "non-contact and non-destructive" manner! It is also capable of measuring materials such as rubber, ceramics, and metals, as well as curved surfaces.

An application for fully automated complexometric titration of zinc (II) in aqueous solution.

Quantification of copper in an aqueous solution by photometric titration.

Achieving the long lifespan of parts and tools! By using diamond special electroplating, we can dramatically enhance the functionality of tools and medical instruments.

Dry plating (vacuum deposition) can be processed on various materials. It can express vibrant colors and is suitable for everything from small items to large exhibition displays.

Vacuum plating is similar to painting, but fundamentally different!

Significantly improved shielding performance! Coating can be applied to various shapes that cannot be handled by metal foils or sealing materials, achieving weight reduction by switching the base material of the components.

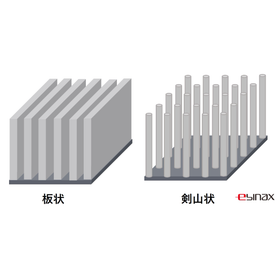

We will introduce points to consider during design and original technologies to enhance cooling effects through plating!

Depending on the shape and quantity of the barrel plating products, we will adjust the hardness of the lead wires and the shape of the contact parts accordingly.

Uniform plating treatment is possible even in deep vias and high aspect ratio through holes!