High-speed continuous processing of films, substrates, etc. is possible under atmospheric pressure! [Sample tests are currently being accepted!]

It is said to be difficult in ALD, but it is possible to form a powder film at low temperature (room temperature) and atmospheric pressure!

Nozzle widths from 10mm to 70mm can be easily replaced with simple work. One machine can accommodate a wide range of applications.

Multi-layer film formation enables the improvement of load-bearing capacity for low-temperature DLC (Diamond-like carbon) thin film hard coatings!

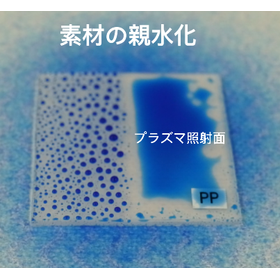

To the 'water-resistant resin,' the power to get wet. With the 'hydrophilization' of plastic, both decoration and adhesion change.

Simultaneously improve quality and efficiency with atmospheric pressure plasma treatment! Suitable for adjusting surface wettability and enhancing adhesion. [Exhibiting at the October 2023 Mechanical Technology Elements Exhibition in Osaka]

Achieving "direct plating without roughening" for difficult-to-plate resins and difficult-to-bond resins, as well as "adhesive-free direct bonding" and "improved adhesion with adhesives"!

Demo units available! We will create samples free of charge for the first time. Inline atmospheric pressure plasma treatment with low-temperature, damage-free using inexpensive gas!

Capable of processing a large amount of powder at once. Approximately 10 kg of powder can be processed in one batch. No restrictions on materials, from metal to resin!

Eliminate surface damage and other issues by using atmospheric pressure and downstream plasma! By changing the type of added gas, surface functionalization molecules can be easily applied!

Compatible with high aspect ratio TGV/TSV. The world's largest chamber size for ALD (1000mm□).

It is now possible to achieve low-temperature DLC (Diamond-like carbon) thin film hard coatings with improved adhesion compared to conventional ta-C!

Atmospheric pressure plasma pre-treatment for coating

It includes various factors such as the variation of the color difference meter and the variation of the equipment (processing) itself!

It is possible to visualize whether the processing status is as intended with a simple change in tone!

[Nationwide Service Available] We can perform thermal spraying on a wide variety of parts! We provide careful support from proposal to thermal spraying, delivery, and aftercare in a consistent system.

Mechanisms of superhydrophobic and superhydrophilic technology, surface modification techniques using coatings, and evaluation of water repellency.