Make pipe wall thickness inspection more efficient with Fujifilm's digital RT system!

Achieving clear images with large aluminum castings.

Clear imaging of 30μm diameter Cu copper wires! A non-destructive X-ray inspection device that keeps the introduction hurdle low with low cost and high performance. Capable of shooting while adjusting the magnification!

From the lab to the fab, from wafers to chips, guiding inspection strategies to the next stage.

[Non-Destructive Testing - RT - IX Series] High-quality X-ray film that meets diverse inspection needs. *Data sheets available!

Make welding inspections more efficient with Fujifilm's digital RT system!

Exploring new possibilities of X-ray imaging! Contributing to the quantification of good products and product development through data accumulation.

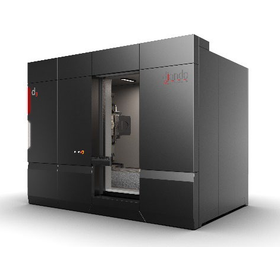

The fusion of cutting-edge technology and high-precision analysis. Clearly visualizing everything from thick components to fine structures, transforming "want to ensure quality" into "can ensure quality."

Proposal for further improvement of inbound and outbound productivity with the "Smart Reel Rack" x "iNsight-2000"!

![Logo_black_with_isolation[1].png](https://image.mono.ipros.com/public/company/pr/image/441/2080629/IPROS13970999704422690263.png?w=280&h=280)