Visualize surface foreign substances, dirt, and scratches! It is well-received as a daily management tool for yield management, quality control, cleaning management, and hygiene management. *Demo units available for loan.

China's top-level 6-sided appearance inspection device 【Our company's overseas procurement product】

New model debut: Innovation in heat exchanger small tube inspection using the latest Remote Field Array (RFA) and AI-ECT!

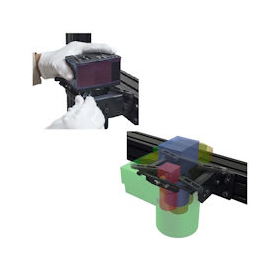

A line scan camera with a variety of shapes and mounting options. Our unique mounting mechanism allows for direct fixation of cameras up to M72 mount.

Non-destructive and non-contact internal inspection of resin, plastic, ceramics, rubber products, and more is possible! It is not affected by transparent or opaque materials, or the color of the product!

With an optical resolution of "1.8μm," it enables very high-precision inspections. It can also accommodate dimensional measurements and inspect two-dimensional punched products, among others.

It is possible to adjust the angle of the optical condition settings, which are important for the operation of the Line Camera, at the appropriate locations. Lighting with different mounting can be securely fixed using a unique mounting mechanism.

Are you struggling with securing cameras and lighting in fixed positions with different angles? Here is an application test stand that achieves angle adjustment, load capacity, and direct fixation of cameras and lighting.

It responds to production speed online and monitors the distance and position between steel cord material wires.

Easily installable on existing lines! A glass edge defect inspection device that uses a special prism to inspect the surface, back, and sides of glass with a single camera.

Causes and countermeasures for 'untapped raw' revealed! High-performance detectors are also available to prevent misrecognition!

"Is it really sufficient to rely solely on inspection and sampling of heat-treated products?" *Explanatory materials are being provided.*

Druck's pressure controller achieves high-speed pressure calibration and control stability simultaneously. There are numerous achievements in quality control and improving production efficiency.

Minimum outer diameter Φ10μm and capable of detecting minimum defects from 2μm! An automatic measurement system for continuous monitoring of surface defects and small diameter irregularities in ultra-fine wires such as monofilaments.

Wavelength 800-1100nm compatible, an ideal near-infrared illumination device for IR transmission imaging.