Achieved an 84% reduction in chocolate stoppage frequency! Improvement, maintenance, equipment management, and development/experimentation all with this one unit! A high-speed camera that visualizes on-site challenges.

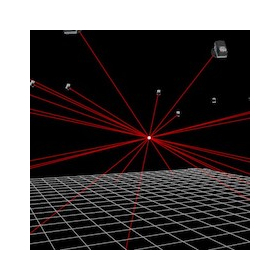

Are you troubled by oil mist, fumes, and foreign substances generated during processing? This is a fine particle visualization system that has solved many problems that are not visible to the naked eye.

It is possible to determine the quality of all prints on a line with a maximum speed of 425 m/min.

Synchronize shooting speed and measurement sampling! Visually verify the mechanism of fatigue destruction.

Low-reflective black anodizing for optical components in high temperatures and special environments to prevent stray light. Capable of withstanding over 300℃!

Low-reflective black anodizing for optical components in high temperatures and special environments to prevent stray light. Capable of withstanding over 300℃! Recommended for sensors and light source devices!

Low-reflective black anodizing for optical components in high temperatures and special environments to prevent stray light. Capable of withstanding over 300℃!

Measures against chocolate stalls have shifted from experience and intuition to a data-driven scientific approach. High-speed cameras that visualize on-site challenges.

![IDS_Logo_RGB_96dpi[1].jpg](https://image.mono.ipros.com/public/company/image/8ed/2067242/IPROS81899547018515056609.jpeg?w=280&h=280)